Introduction

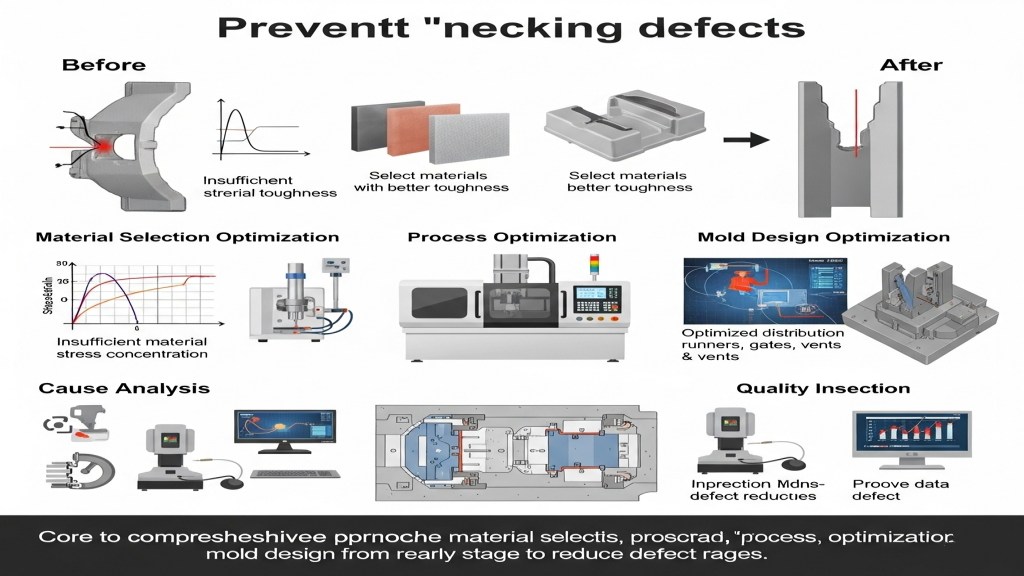

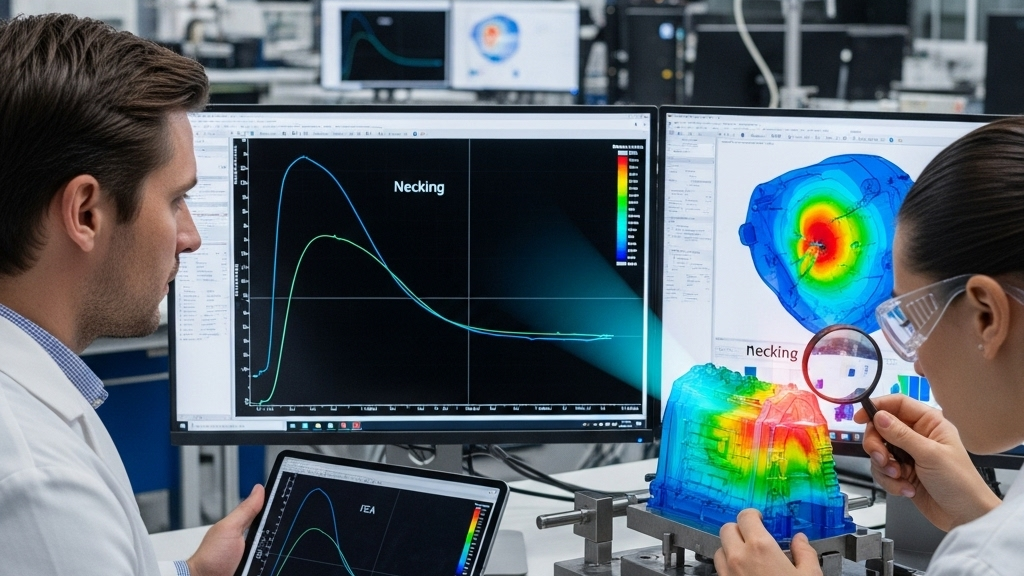

In the stress-strain curve of injection molded parts, "necking" refers to the sudden reduction in local cross-sectional area, which leads to decreased part strength and surface quality. In mass production, this defect not only affects performance but can also cause serious quality risks. The causes are often linked to insufficient material toughness, stress concentration, and improper process control.

To avoid necking, it is necessary to consider material selection, process optimization, and mold design together. By distributing stress evenly and controlling molding parameters, the risk of localized deformation can be greatly reduced. Introducing these optimization measures early in the project can significantly reduce defect rates during production.

How to reduce the risk of necking at the material selection stage?

Material toughness and ductility are the foundation for preventing necking. Choosing materials with higher yield strain and fracture elongation can improve a part’s ability to resist localized strain concentration. Adding toughening agents or using blend modifications are common approaches to improve overall plasticity and crack resistance.

- Toughening Modification: Improves a material’s deformation ability under stress.

- Fiber Reinforcement: Balances material strength and toughness.

- Molecular Weight Adjustment: Controls ductility through chain length.

- Adding Stress-Relief Additives: Reduces microcracks during processing and use.

😊 Material selection is the first step to preventing necking.

Which process parameter adjustments help suppress necking?

Temperature, pressure, and holding time in injection molding directly affect stress distribution. By optimizing these parameters, localized strain concentration can be reduced, lowering the probability of necking. Proper melt flow and cooling rates are also key to ensuring uniform molding.

- Temperature Control Optimization: Keeps the melt in optimal flow state.

- Segmented Holding Pressure: Slows internal stress build-up.

- Injection Speed Adjustment: Avoids uneven filling from excessive speed.

- Balanced Cooling: Prevents excessive local shrinkage differences.

⚙️ Process parameter adjustments can significantly improve stress distribution.

How can mold structure design reduce necking?

Mold design directly affects stress transfer and distribution in the part. Optimizing gate location, runner layout, and cavity wall thickness reduces localized stress concentration areas. At the same time, proper venting and cooling system layouts improve part consistency.

- Gate Position Optimization: Prevents excessive stress in a single area.

- Balanced Runner Design: Ensures uniform melt distribution.

- Wall Thickness Consistency: Minimizes necking from uneven shrinkage.

- Enhanced Cooling Layout: Reduces residual molding stress.

🛠️ Mold structure optimization is a key method for necking prevention.

Comparison of Different Measures for Necking Prevention

| Measure Type | Cost | Prevention Effect | Applicable Scope |

|---|---|---|---|

| Material Toughening | Medium | High | General |

| Process Optimization | Low | Medium-High | Mass Production |

| Mold Improvement | High | High | Long-Term Projects |

| Cooling Optimization | Medium | Medium-High | Precision Parts |

Long-Term Performance Assurance

During the long-term service of injection molded parts, performance stability is a core competitive advantage for enterprises. By integrating stress management strategies throughout the design and production process, the product lifespan can be significantly extended. This preventive quality control not only reduces rework and scrap rates but also improves customer satisfaction and brand reputation.

1.Full-Process Stress Monitoring: Continuously track material and process performance during production.

2.Structural Durability Testing: Ensure product reliability under extreme conditions.

3.Customer Feedback Tracking: Feed back usage data to design and process improvements.

4.Continuous Improvement Mechanism: Keep optimizing production and design strategies.

Conclusion

Preventing necking in the stress-strain curve requires coordinated optimization of materials, processes, and molds. Only by controlling the entire chain from the source to the finished product can the mechanical performance and appearance quality of parts be ensured. When formulating production strategies, enterprises should take preventive design and long-term quality management as core elements to achieve higher production efficiency and stronger market competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!