Introduction

Precision mold processing and core pulling mechanisms are crucial elements in modern injection molding. As product demands become increasingly complex, the precision and complexity of molds continue to rise. The advancement of precision processing technologies enables mold production to meet higher standards, while efficient core pulling mechanisms allow for the successful production of molds with complex shapes. The design and processing of molds directly determine the quality and production efficiency of the final product.

How to improve the precision of molds?

To improve the precision of molds, accurate processing technologies and equipment are essential. Precision processing technologies ensure that each mold component meets high dimensional standards through meticulous control. High-precision CNC machines and advanced laser technologies are the core of precision processing, enabling them to meet increasingly stringent manufacturing standards.

- Precision processing technology: Ensures that every part of the mold is precisely accurate with high-precision equipment.

- Application of CNC systems: Modern CNC technology offers higher precision processing capabilities.

- Importance of material selection: Using high-precision materials can enhance the mold's service life.

- Advanced inspection technology: The application of advanced inspection technology ensures precision control during the processing.

Precision processing technology effectively improves the quality and efficiency of mold production.

How does the core pulling mechanism optimize the mold production process?

The core pulling mechanism plays a key role in mold design, especially in the production of injection parts with complex structures. By properly designing the core pulling mechanism, mold production efficiency can be greatly improved. Innovative core pulling technologies not only reduce production cycles but also ensure the smooth forming of parts with complex shapes.

- Automated core pulling systems: Automated core pulling shortens production cycles and increases efficiency.

- Multi-point core pulling design: Multi-point core pulling technology ensures smooth demolding of parts with multiple angles.

- Compatibility of sliders and guides: Accurate slider and guide design enhances mold stability.

- Optimized core pulling angles: Optimizing core pulling angles helps reduce mold wear.

Optimized core pulling mechanisms enhance production efficiency and reduce costs.

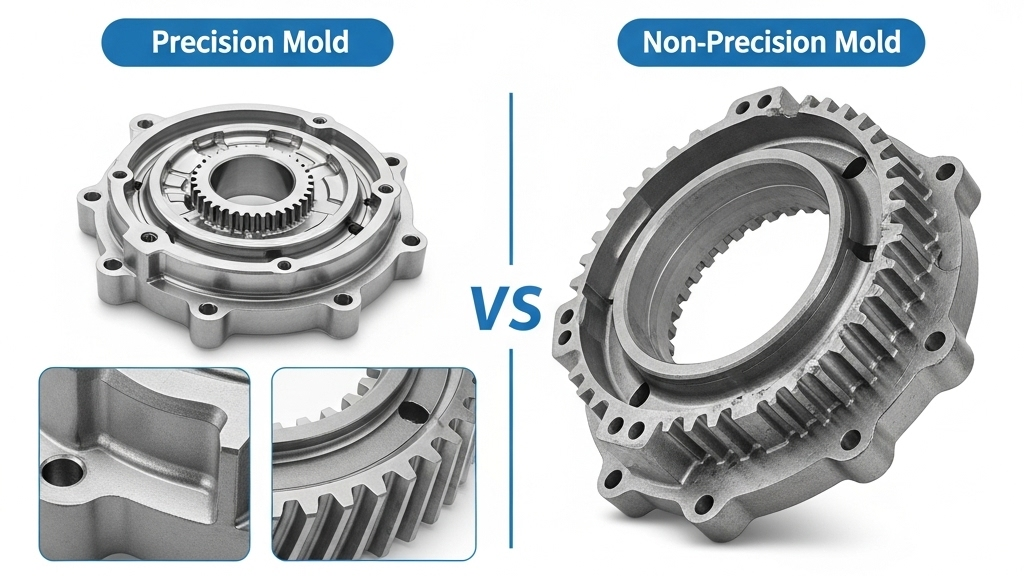

How does precision mold processing affect the final product quality?

Precision mold processing directly affects the final product quality, especially for products requiring high precision and complex shapes. Precision processing ensures the accuracy of mold dimensions, which in turn affects the dimensional stability and surface quality of the injection parts. Through precision processing technology, the details and structure of the product are perfectly presented.

- Precision and stability: Precision processing ensures consistency and stability of the product.

- Material compatibility: Precision processing materials influence the product's durability.

- Detail control: Accurate control of every detail of the mold ensures the final product's quality.

- Long-term stability: Precision processing ensures the mold's long-term stability and production capability.

Precision processing ensures the high quality and long-lasting performance of products.

Comparison of Precision Mold Processing Technologies

| Technology | Equipment Required | Precision Control | Application Range | Advantages | Disadvantages |

|---|---|---|---|---|---|

| CNC Processing | High-precision CNC machines | Ultra-high precision | High-demand molds | Improved production precision | High equipment cost |

| Laser Processing | Laser equipment | Ultra-high precision | Fine structures | High precision, versatile | Slower speed |

| EDM Processing | EDM machines | High precision | Hard materials | High precision, complex shapes | High consumption |

| 3D Printing | 3D printer | High precision | Rapid prototyping | Short production cycle | Lower precision |

Title

Precision processing and core pulling technologies are closely related. With the continuous development of technology, the precision requirements for molds are increasing, and core pulling mechanisms are continuously optimized to meet the needs of complex production. Efficient precision processing technology and advanced core pulling design are the foundation of modern mold manufacturing. By adopting advanced technologies, not only can the precision and efficiency of mold production be improved, but production costs can also be reduced.

- Technological Advantages of Precision Processing: Improving mold production precision through accurate control.

- Optimization Path of Core Pulling Technology: Effectively reducing production cycles and improving efficiency.

- Innovation in Mold Design: Ensuring the smooth forming of complex structures.

- Improvement in Production Efficiency: Proper design extends the mold's service life.

Conclusion

Precision mold processing and core pulling mechanisms play a critical role in the injection molding industry. Through precision processing technologies and efficient core pulling designs, high-quality molds and production efficiency can be ensured. Optimizing these two elements significantly enhances the precision and efficiency of production, bringing greater market competitiveness to enterprises.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!