Introduction

In injection molding, plasticizer residue often affects the physical properties and service life of products. By adjusting formulation and process parameters, manufacturers can significantly reduce residue levels and improve overall quality. Minimizing plasticizer residue is the key to enhancing product stability.

At the same time, choosing suitable raw materials and additives can help achieve higher environmental standards. Optimized processes not only improve appearance and performance but also create market advantages in green manufacturing. Companies that resolve plasticizer residue issues will stand out in competition.

How can process optimization reduce plasticizer residue?

In injection molding, process optimization directly influences the volatilization and residue levels of plasticizers. By precisely controlling temperature, pressure, and cooling speed, manufacturers can minimize incomplete plasticization and excessive residue. Process optimization is the most direct way to reduce plasticizer residue.

- Temperature Control: Proper temperature ensures full dispersion of plasticizers

- Pressure Management: Reasonable injection pressure prevents localized excess residue

- Cooling Speed: Stable cooling helps plasticizers evaporate uniformly

- Mold Optimization: Well-designed flow channels reduce stagnation zones

😊 Optimizing process conditions is the key to reducing plasticizer residue

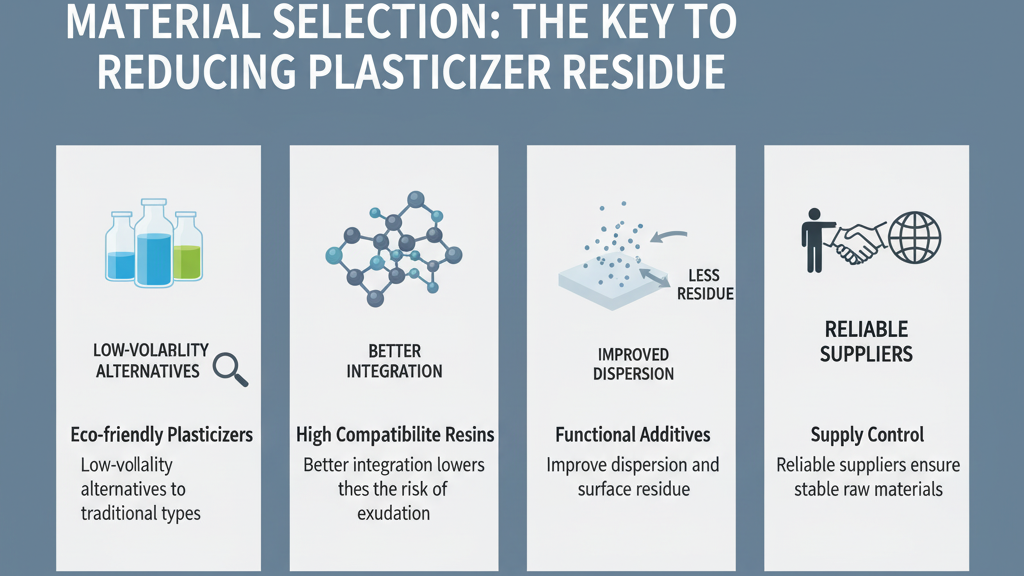

Can material selection reduce residue?

Material choice is a decisive factor in plasticizer usage. Using low-migration plasticizers and highly compatible resins can reduce residue at the source. Raw materials determine dispersion efficiency and volatilization of plasticizers.

- Eco-friendly Plasticizers: Low-volatility alternatives to traditional types

- High Compatibility Resins: Better integration lowers the risk of exudation

- Functional Additives: Improve dispersion and reduce surface residue

- Supply Chain Control: Reliable suppliers ensure stable raw materials

🔍 Choosing the right material effectively prevents excessive residue

What testing methods ensure residue control?

Testing methods provide assurance for controlling plasticizer residue. With infrared spectroscopy, gas chromatography, and other techniques, manufacturers can measure plasticizer levels precisely. Testing is essential to ensure compliance with quality and environmental standards.

- Gas Chromatography: Accurately measures residual compounds

- Infrared Spectroscopy: Quickly detects residue trends in materials

- Solvent Extraction: Quantifies plasticizer release levels

- Batch Sampling: Ensures stable residue levels during production

🧪 Testing methods help establish a reliable quality control system

Comparison of Plasticizer Residue Solutions

| Method | Cost | Durability | Difficulty | Eco Performance |

|---|---|---|---|---|

| Process Control | Mid | High | Mid | High |

| Material Change | High | High | Mid | High |

| Additives Use | Mid | Mid | Mid | Mid |

| Residue Testing | Mid | High | High | High |

Choosing the right solution will quickly improve product quality and competitiveness, contact us

The Business Value of Residue Control

In injection molding, controlling plasticizer residue is not only a quality requirement but also a market-driven demand. With increasing environmental regulations, low-residue products can enter premium markets more easily. Reducing residue translates into stronger brand image and larger market share.

1.Eco Certification: Increases access to international markets

2.Customer Trust: Low-residue products strengthen long-term partnerships

3.Brand Differentiation: Residue control adds competitive advantage

4.Market Expansion: Meets stricter industry-specific environmental requirements

Conclusion

Plasticizer residue issues in injection molded products can be resolved through systematic improvements in process, materials, and testing. While addressing this challenge, companies also create stronger market barriers and enhance brand value. Reducing residue is not just a product improvement but a step toward strategic business growth.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!