Introduction

In the injection molding industry, the stability of HDT performance determines whether products can maintain their shape and function under high-temperature conditions. We have accumulated numerous HDT success stories, and this expertise directly helps businesses shorten their development cycles. Every case proves the critical importance of stable HDT.

Our team combines lab testing with real-world applications to develop practical solutions. These cases not only demonstrate technical strength but also deliver tangible market advantages for clients. Turning experience into customer value is what drives us forward.

How Can HDT Cases Enhance Injection Molded Part Reliability?

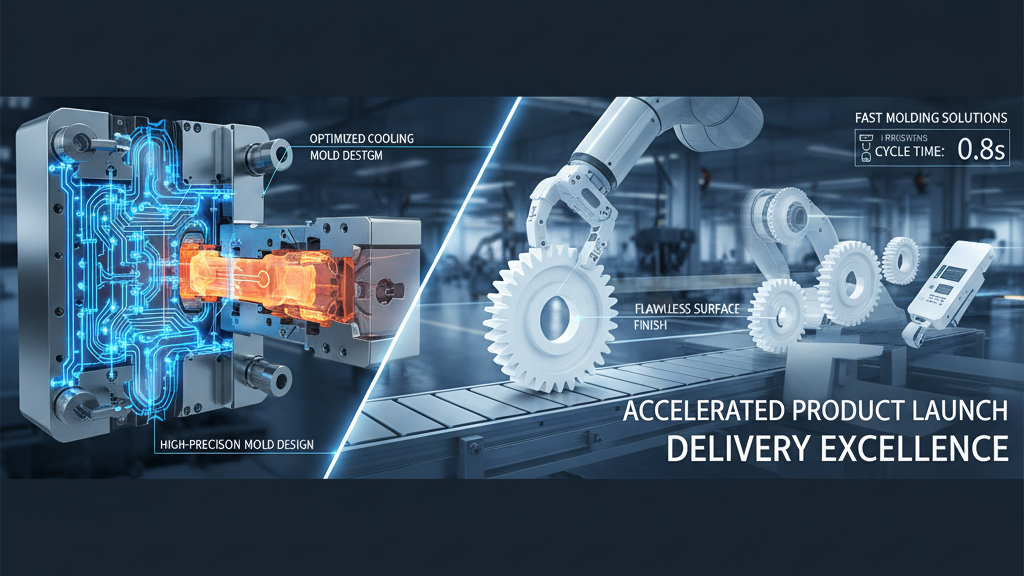

HDT cases showcase effective methods for improving heat deflection temperature across different engineering plastics. By optimizing mold design and process control, products remain stable under high heat. This reliability translates directly into durability and customer trust.

- Mold Optimization: Proper cooling design reduces thermal stress.

- Process Stability: Maintaining consistent temperature and pressure ensures HDT performance.

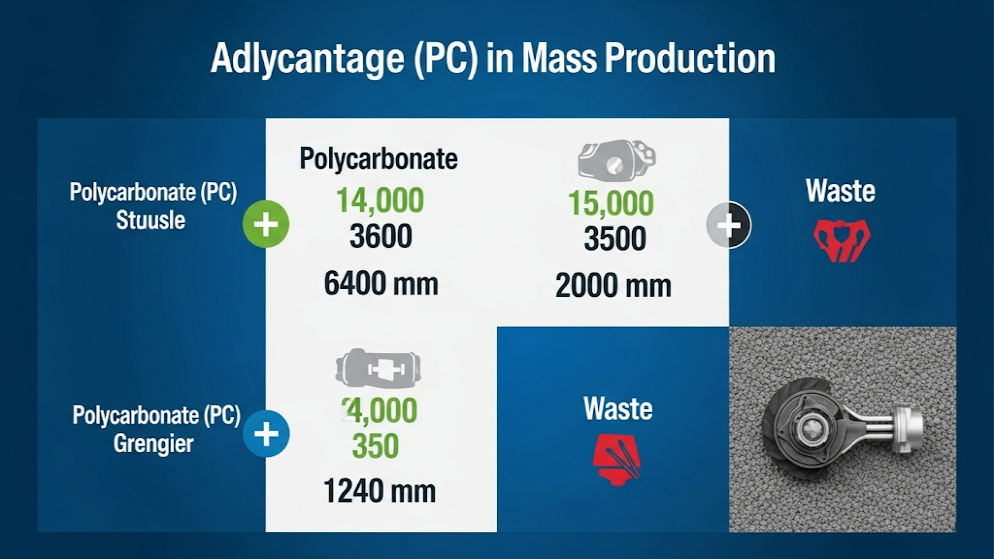

- Material Selection: Choosing the right polymer systems for specific uses.

- Customer Validation: End-user feedback further confirms reliability.

😊 HDT cases keep products stable in demanding environments.

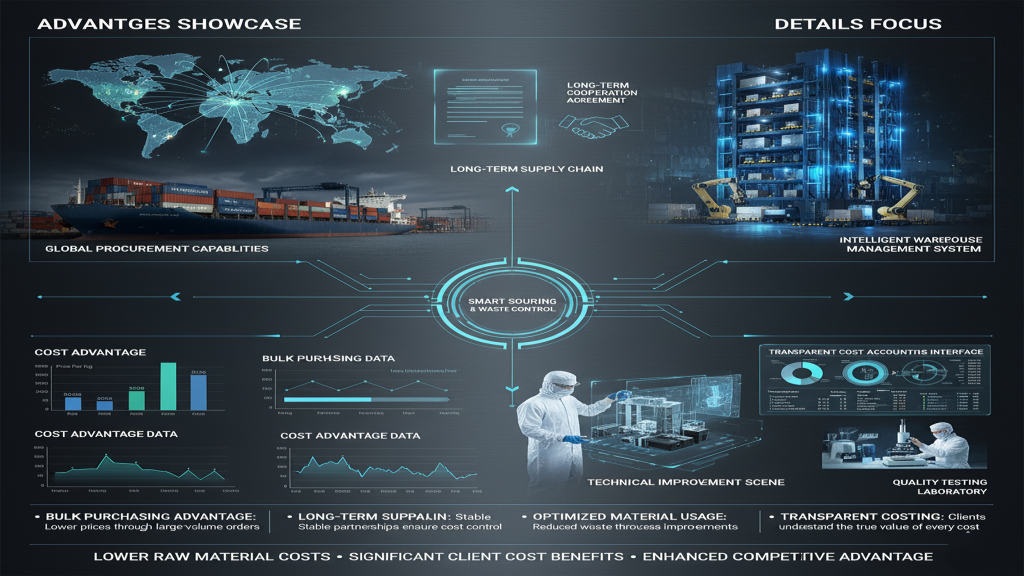

How Do HDT Solutions Drive Cost Optimization?

In our cases, HDT optimization is not just about performance but also a key to cost control. By reducing part failures and rework, overall production efficiency is significantly improved. Lower costs come hand-in-hand with stronger market competitiveness.

- Process Improvements: Lower defect rates directly reduce costs.

- Extended Mold Life: Optimized designs minimize tool wear.

- Better Material Utilization: Smart formulations reduce waste.

- Higher Productivity: Shorter cycles boost output.

💡 HDT cases create a balance between performance and cost savings.

How Do Our HDT Cases Accelerate Your Time-to-Market?

Successful HDT cases mean risks can be predicted and avoided early in development. Our tailored solutions help clients shorten development timelines, enabling faster product launches. Quick market entry leads to faster returns.

- R&D Guidance: Minimize trial-and-error during development.

- Prototype Validation: Early simulations accelerate evaluation.

- Mature Processes: Reduce uncertainties in mass production.

- Supply Chain Support: Synchronized progress shortens delivery schedules.

🚀 HDT cases give clients a faster path to market success.

Comparative Value of HDT Case Applications

| Application Area | Cost Advantage | Reliability | Speed to Market | Competitiveness |

|---|---|---|---|---|

| Mold Optimization | High | High | Medium | High |

| Material Upgrade | Medium | High | High | Medium |

| Process Refinement | High | Medium | High | High |

| Integrated Flow | High | High | High | High |

How Do HDT Success Stories Empower Multiple Industries?

Our HDT cases go beyond automotive parts, extending into electronics, appliances, construction, and consumer goods. By leveraging cross-industry expertise, we can quickly replicate proven solutions. This broad experience helps clients face diverse market challenges with confidence.

1.Automotive: Ensure parts remain reliable under prolonged high temperatures.

2.Electronics: Support performance needs of heat-exposed devices.

3.Construction: Deliver more durable plastic components.

4.Consumer Products: Balance aesthetics with long-term durability.

🌍 HDT success stories are scaling across more industries worldwide.

Conclusion

HDT success stories are not just technical showcases but proven tools for solving real production challenges. The lessons we’ve learned are helping clients reduce risks, control costs, and accelerate product launches. The true value of HDT cases lies in keeping businesses ahead in competitive markets.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!