Introduction

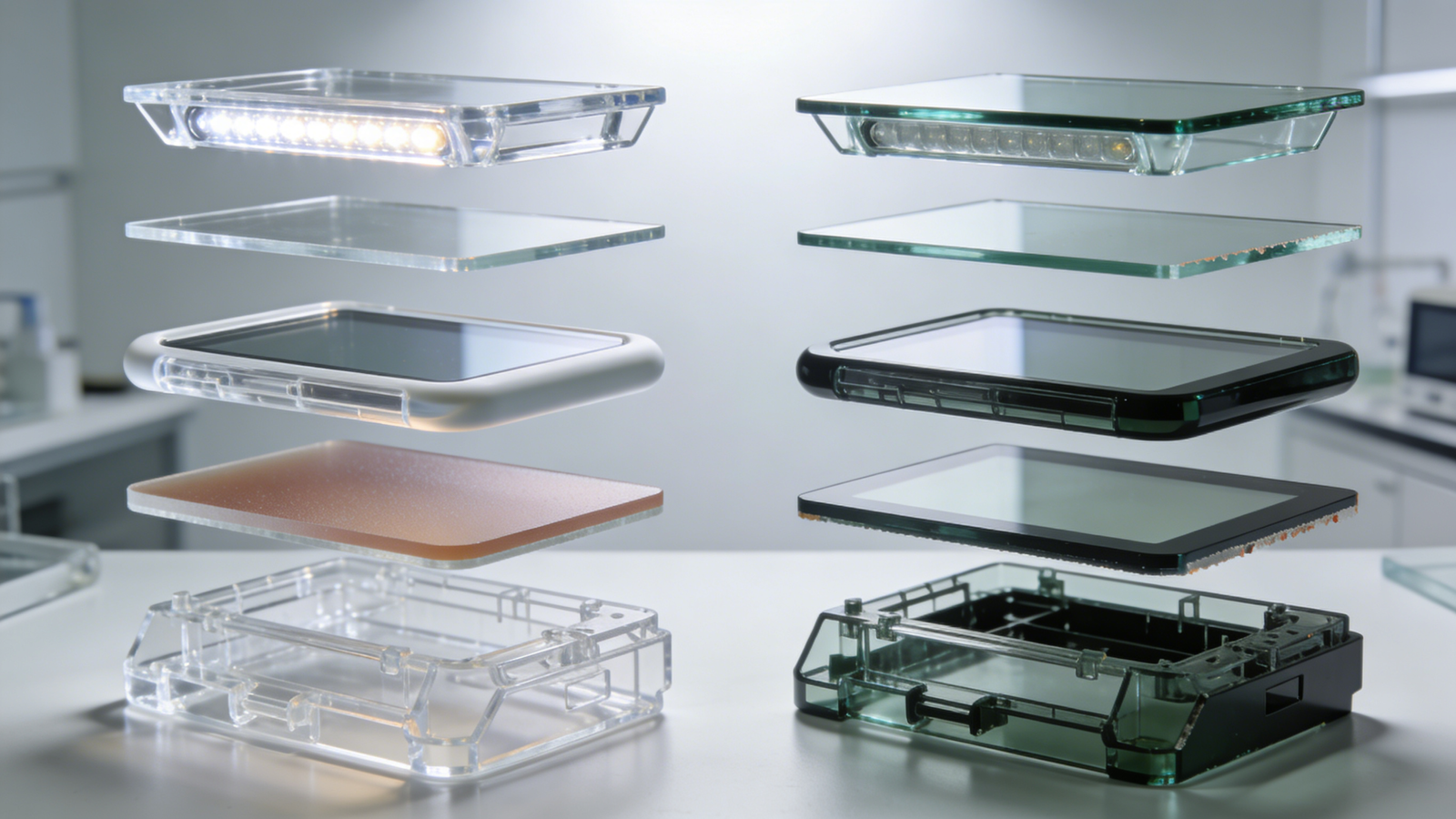

In lighting, display, home appliance, and industrial appearance components, the choice of transparent materials is gradually shifting from traditional glass to engineering plastics, with PMMA transparent injection molding becoming a frequent option. The material itself represents only part of the cost; the real differentiation lies in processing methods, yield rates, and supply chain efficiency.

From Xiamen Ruicheng’s hands-on manufacturing perspective, more customers are no longer focused solely on unit price but are seeking predictable and controllable total costs during mass production. The value of PMMA transparent injection molding is reflected in end-to-end cost optimization from design to delivery.

Is PMMA transparent injection molding really cheaper than glass?

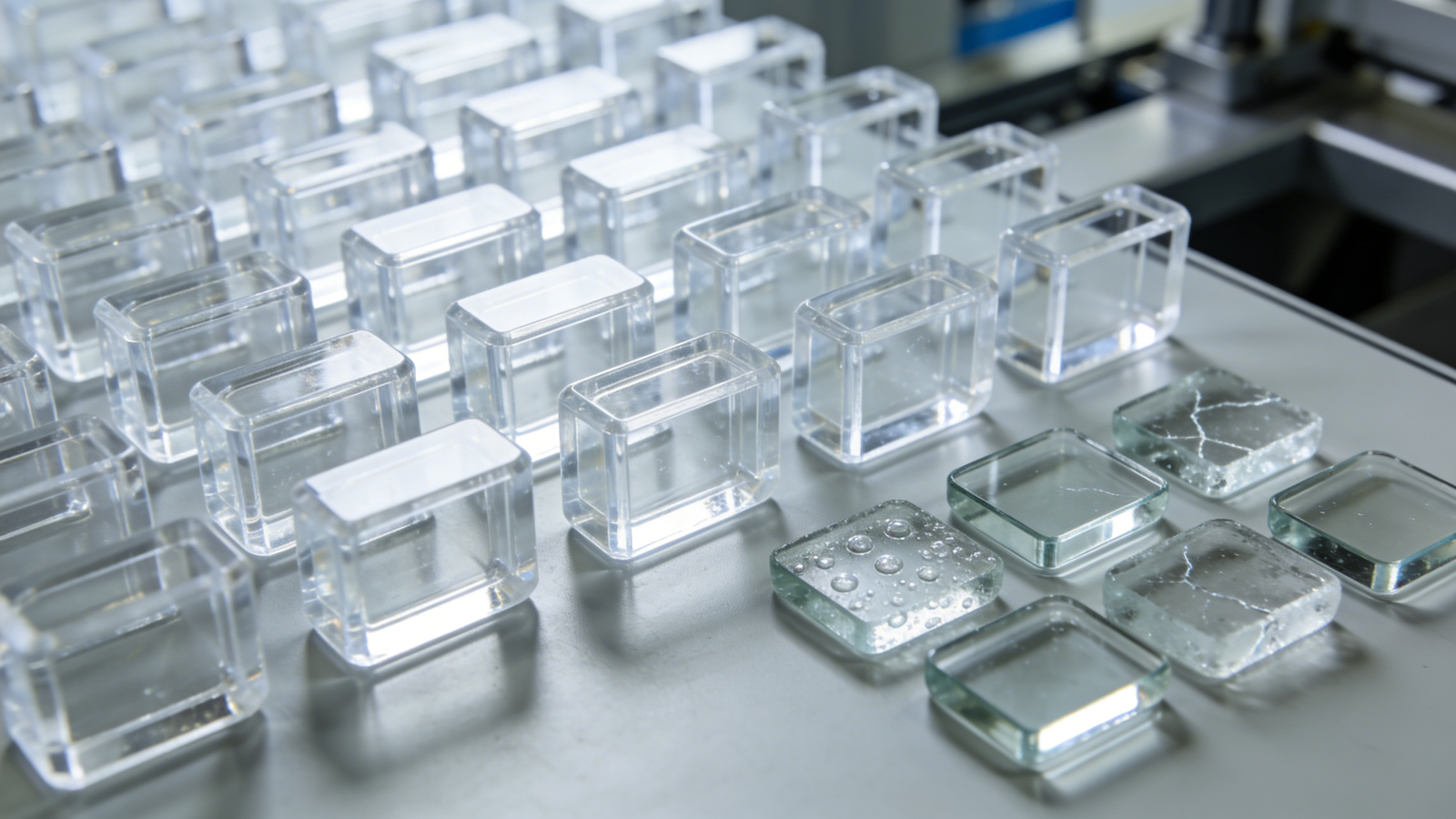

Under equivalent appearance and light-transmission requirements, PMMA transparent injection molding can significantly dilute unit costs after the initial mold investment through high repeatability and automated production, especially for medium- to high-volume projects. Compared with glass cutting, thermal bending, and secondary polishing, PMMA injection molding shows clear advantages in yield stability and cycle time. In practical projects, the combination of PMMA material and injection molding has consistently reduced scrap rates and labor dependency.

Mold amortization: Mold costs are rapidly spread across stable volumes, driving continuous unit cost reduction.

Processing cycle: Injection molding delivers predictable and repeatable cycle times, supporting scalable production planning.

Yield control: High dimensional consistency minimizes rework and cosmetic defects.

Integrated delivery: One-shot molding reduces secondary operations and coordination costs.

📊 Based on Xiamen Ruicheng’s mass production cases, the cost advantage of PMMA injection molding becomes fully evident at scale.

Where do the main cost differences come from?

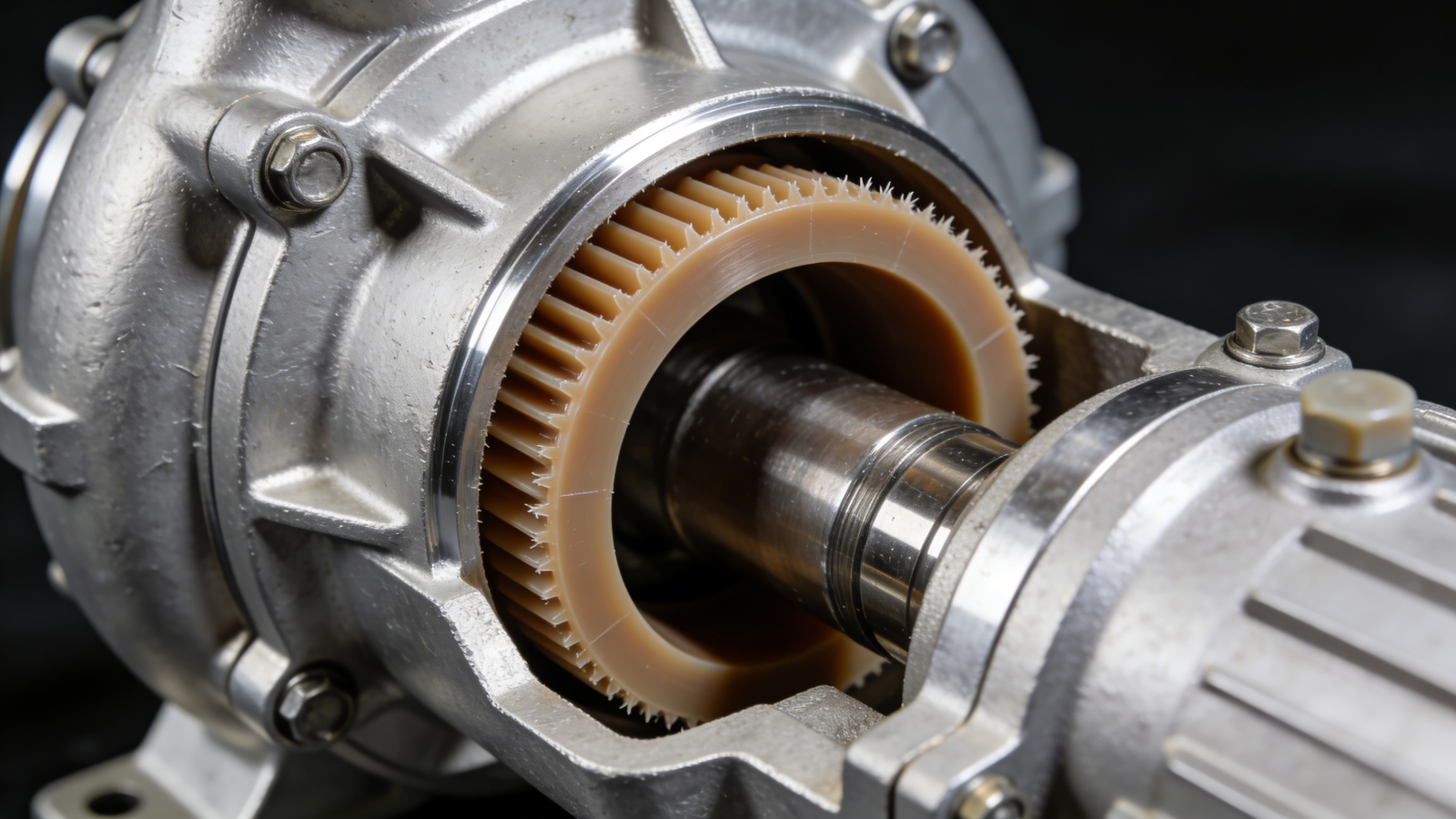

The cost gap between PMMA transparent injection molding and glass processing goes far beyond raw material pricing and extends throughout the entire manufacturing chain. Glass processing relies heavily on manual expertise and process stability, while PMMA injection molding is more suitable for standardized replication. A comparison between transparent plastic parts and industrial glass processing clearly reveals the structural cost differences.

Material utilization: Injection molding allows runner recycling, while glass cutting waste is irreversible.

Process complexity: Glass requires multiple cold and hot processing steps, increasing overall costs.

Logistics and breakage: PMMA is lighter and impact-resistant, reducing transport risks and packaging expenses.

Consistency risk: Injection molding ensures batch stability, minimizing claims and rework caused by variation.

📦 Cost differences are rarely driven by a single factor, but rather by cumulative effects across multiple stages.

Which applications are more suitable for PMMA?

Not all transparent components are ideal candidates for PMMA replacing glass, but in specific applications the advantages are clear. When products emphasize appearance consistency, structural integration, and scalable replication, PMMA transparent injection molding is often more economical. Among Xiamen Ruicheng’s customer projects, lamp covers and display panels are the most common substitution scenarios.

Medium- to high-volume programs: Stable annual demand allows injection molding to outperform glass on the cost curve.

Complex geometries: Features such as clips and ribs that are difficult for glass can be molded in one step.

Lightweight requirements: Weight reduction lowers system-level transportation and installation costs.

Safety considerations: Impact resistance reduces breakage risk, making it suitable for public environments.

💡 The key is not whether PMMA can be used, but whether its system-level value can be maximized.

Key cost comparison between PMMA injection molding and glass processing

| Comparison Dimension | PMMA Injection Molding | Glass Processing | Cost Impact | Buyer Focus |

|---|---|---|---|---|

| Material loss | Recyclable | Non-recyclable | Lower with PMMA | Long-term material cost |

| Processing cycle | Stable and fast | Fragmented steps | PMMA advantage | Delivery predictability |

| Labor dependency | Low | High | PMMA saves | Labor cost |

| Transport breakage | Low | High | PMMA safer | Risk cost |

Wondering whether your product is suitable for this substitution path? Feel free to contact us directly.

How to amplify cost advantages from the design stage

In Xiamen Ruicheng’s project experience, the real cost gap is often determined during early design decisions. Only when structure, wall thickness, and mold concepts are optimized together can the economic value of PMMA transparent injection molding be fully realized. This affects not only unit pricing, but also long-term production stability and maintenance costs.

1.Structural integration: Use injection molding to combine multiple functions and reduce part count.

2.Wall thickness control: Uniform design minimizes internal stress and cosmetic defects.

3.Mold planning: Early DFM evaluation helps avoid costly mold revisions.

4.Mass production validation: Pilot data supports reliable long-term cost forecasting.

Frequently Asked Questions (FAQ)

Question: Where does the core cost advantage of PMMA transparent injection molding lie?

Answer: Buyers should evaluate material utilization, mold amortization, yield rates, and delivery stability together. Xiamen Ruicheng helps quantify these factors through DFM analysis and production data.

Question: What information is required to quickly assess PMMA replacing glass?

Answer: Providing drawings, annual demand, and application scenarios allows Xiamen Ruicheng to deliver feasibility feedback and cost ranges efficiently.Question: Is PMMA injection molding suitable for small-volume projects?

Answer: If the structure is complex or future scale-up is expected, pilot runs and phased tooling strategies can effectively manage early investment risks.

Question: How are quality or delivery issues handled?

Answer: Xiamen Ruicheng operates a clear quality judgment and response mechanism to ensure issues are resolved within agreed timelines.

Question: Do you support customization and ongoing optimization?

Answer: Yes, from material selection to mold and process parameter optimization, we support continuous improvement throughout the product lifecycle.

Conclusion

Whether PMMA transparent injection molding is more cost-effective than glass depends on a system-level evaluation. When volume, structure, and delivery stability are integrated into the decision model, PMMA injection molding often demonstrates more sustainable economic value. From Xiamen Ruicheng’s practical experience, successful substitution is driven by informed early decisions rather than corrective actions later.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!