Reducing maintenance is a continuously pursued goal in the industry. Traditional lubrication methods bring extra work and potential failures. Delrin (Polyoxymethylene, POM), with its self-lubricating properties, provides a new approach to reducing maintenance. This article will explore the self-lubricating mechanism of Delrin and its applications in reducing maintenance needs from a professional perspective.

Delrin's self-lubricity stems from its unique material properties. So, how can this advantage be effectively utilized in practical applications to reduce maintenance requirements? Next, we will explore key design and application strategies, and analyze its potential in maintenance-free or low-maintenance designs through case studies.

How Does Delrin Achieve Self-Lubrication?

Delrin (Polyoxymethylene, POM) possesses excellent self-lubricating properties thanks to its unique molecular structure, which endows the material with an inherent low coefficient of friction and wear resistance. Compared to other engineering plastics, Delrin can more effectively reduce energy loss and material wear during sliding friction, giving it a significant advantage in various oil-free or low-oil lubrication applications.

- Delrin's Self-Lubricating Mechanism and Characteristics: Delrin's unique molecular structure and high crystallinity give it an inherent low coefficient of friction and excellent wear resistance, allowing it to exhibit tribological properties superior to many other engineering plastics under oil-free or low-oil lubrication conditions.

- Applications Benefiting from Delrin's Self-Lubrication: Various mechanical components and application scenarios such as sliding bearings, gears, and guide rails can significantly reduce the need for external lubrication through Delrin's self-lubricating properties.

- Design Considerations for Achieving Low Maintenance: Rational material selection, component clearance, surface finish, load distribution, and consideration of PV values are key to maximizing the self-lubricating advantages of Delrin.

- Additional Benefits of Delrin's Self-Lubrication: In addition to reducing maintenance, Delrin's self-lubricity can also extend equipment life, improve operating efficiency, reduce noise, improve cleanliness, and reduce long-term operating costs.

Which Components/Applications Benefit Most from Delrin's Self-Lubrication?

In mechanical design considerations, the performance and reliability of certain critical components and specific application scenarios can be significantly enhanced by using Delrin (Polyoxymethylene, POM) materials with self-lubricating properties. By utilizing Delrin's low coefficient of friction and wear resistance, designers can effectively reduce or even eliminate the dependence on traditional external lubrication systems, thereby simplifying structures and reducing maintenance needs.

- Light to Medium Load Sliding Bearings and Bushings: Delrin significantly reduces friction and wear in light to medium load sliding applications, reducing the need for lubrication and making it suitable for a variety of industrial equipment.

- Low-Noise and Smooth-Running Gears: Delrin can be used to manufacture low-noise, wear-resistant gears, especially suitable for light to medium load applications where cleanliness is required.

- Sliding Components in Humid and Corrosive Environments: Delrin's moisture and corrosion resistance make it an ideal sliding material for reducing lubrication needs in harsh environments.

- Linear Motion with High Cleanliness Requirements: Delrin's self-lubricating properties make it effective in avoiding lubrication contamination in linear motion components with high cleanliness requirements such as medical and food industries.

How to Design and Select Delrin for Low Maintenance?

To fully exploit the self-lubricating potential of Delrin (Polyoxymethylene, POM) and achieve low-maintenance or even maintenance-free goals in practical applications, engineers need to consider carefully and adopt best practices in multiple stages, including material selection, component design, and manufacturing. Through refined design and manufacturing processes, the inherent properties of Delrin can be maximized, improving equipment reliability and long-term operational efficiency.

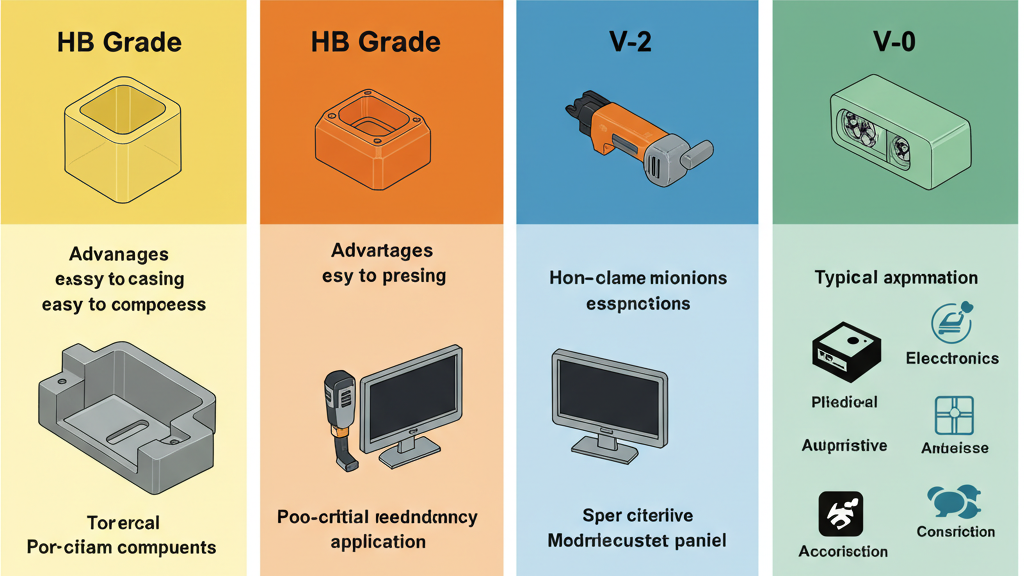

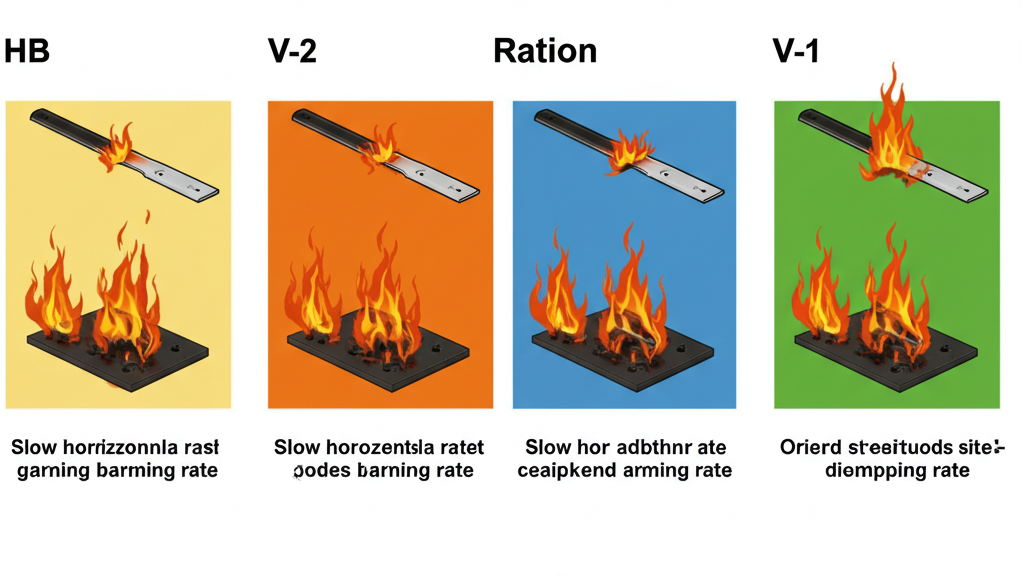

- Precise Material Selection Adapts to Working Conditions: Accurately selecting the appropriate Delrin grade and mating materials according to actual working conditions is the basis for leveraging the self-lubricating advantages.

- Optimize Design to Promote Lubrication: Rational component geometry design and surface treatment can effectively promote the self-lubricating performance of Delrin.

- Precision Manufacturing Ensures Quality: Precise machining and manufacturing processes are key to ensuring that Delrin components have excellent tribological properties.

- Comprehensive Consideration of Operating Conditions: Fully considering the operating environment and taking protective measures helps to maintain the self-lubricating effect of Delrin and extend its service life.

Characteristics and its maintenance advantages

| Key Self-Lubricating Properties of Delrin | Resulting Maintenance Advantages | Typical Application Examples |

|---|---|---|

| Inherent Low Coefficient of Friction | Reduced friction, lower heat generation, extended component life | Sliding bearings, guide rails |

| Excellent Wear Resistance | Reduced material wear, longer replacement intervals | Gears, chain guides |

| No or Reduced External Lubrication | Avoids lubricant maintenance and contamination, lower maintenance costs | Food machinery, medical devices |

| Good Moisture/Corrosion Resistance | Maintains self-lubrication in harsh environments, reduced environment-related maintenance | Components in humid/corrosive environments |

Additional Advantages of Self-Lubricating Delrin

Delrin's (Polyoxymethylene, POM) self-lubricating properties not only significantly reduce the need for external lubrication in mechanical components, thereby reducing maintenance workload and costs, but also demonstrate multiple advantages in improving overall equipment performance. By reducing friction and wear, Delrin helps to extend the life of equipment, improve operating efficiency, and reduce noise.

1.Extends Equipment and Component Life: Delrin's low friction and wear resistance directly reduce wear, significantly extending the service life of equipment and components.

2.Improves Operating Efficiency and Reduces Energy Consumption: Lower frictional resistance makes equipment run more smoothly, requiring less energy, thereby improving efficiency and reducing energy consumption.

3.Enables Quieter and Smoother Operation: Delrin's self-lubricity reduces friction noise and vibration, making equipment run more quietly and smoothly.

4.Suitable for High Cleanliness Applications: Eliminating or reducing the use of lubricants makes Delrin suitable for application scenarios that are highly sensitive to contamination.

Conclusion

Leveraging Delrin's self-lubricating properties can also extend the lifespan of equipment and components, improve operational efficiency, reduce energy consumption, enable quieter and smoother operation, and meet the stringent requirements of high-cleanliness applications. A deep understanding and effective utilization of Delrin's self-lubricating characteristics are of significant strategic importance for optimizing mechanical designs, reducing long-term operating costs, and enhancing overall equipment performance.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!