Introduction

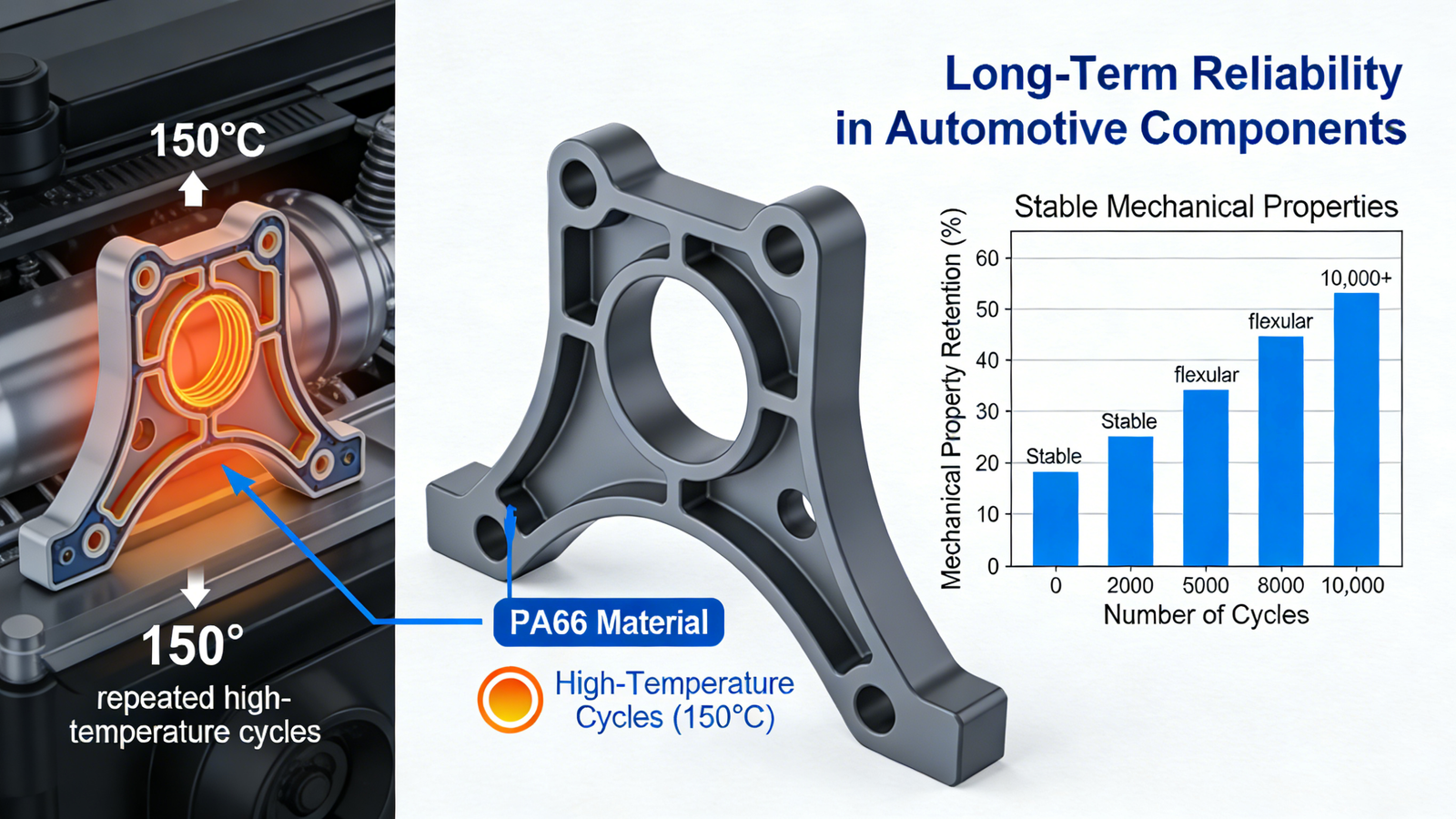

Automotive-grade PA66 with glass fiber plays a structural role in EV battery systems, requiring heat resistance, dimensional stability, and long-term durability. With systemized material control and precision mold engineering, Xiamen Ruicheng ensures that each housing performs reliably even under extreme environments.Dimensional stability under heat, load, and vibration is the core value of automotive-grade housings.

Stable mass delivery depends not only on materials but on consistent process windows, controlled fiber orientation, and a robust QC framework. Through machine capability, molding consistency, and batch-tracking systems, long-term supply stability can be achieved.Durability and batch consistency remain the primary goals of GF-PA66 battery housing manufacturing.

How can molding stability be ensured for automotive-grade GF-PA66 battery housings?

GF-PA66 requires stable melt temperature, packing curves, and fiber-flow consistency to ensure dimensional accuracy and mechanical strength. A controlled processing window keeps thermal behavior predictable, while optimized mold cooling enhances flatness and reduces warpage.Balanced molding parameters significantly improve structural stability and batch consistency.

- Process Window Control: Maintain temperature, pressure, and cooling rhythm to reduce variation.

- Cooling Optimization: Uniform cooling ensures consistent shrinkage.

- Fiber Orientation Management: Improves impact strength and reduces deformation.

- Material Drying Discipline: Prevents moisture-related dimensional issues.

😊 The key is a replicable, long-term stable injection molding parameter system.

How does mold design influence dimensional consistency in GF-PA66 housings?

GF-PA66 is highly sensitive to fiber flow patterns, causing directional shrinkage if mold design is insufficient. Compensation design, optimized gating, and balanced rib structure help achieve long-term dimensional consistency. A well-balanced flow path ensures stable filling and uniform part geometry.Accurate deformation compensation and gating strategy lay the foundation for dimensional stability.

- Deformation Compensation: Modify tooling based on CAE findings.

- Balanced Runner Layout: Reduce stress concentration caused by fiber deviation.

- Optimized Rib Layout: Prevents localized warp.

- Stable Mold Steel: Ensures predictable thermal behavior.

🔧 A mold’s ability to “predict and compensate” defines mass-production dimensional accuracy.

How do manufacturers ensure batch consistency in mass delivery of GF-PA66 battery housings?

Batch consistency relies on material traceability, controlled molding limits, and a complete inspection system. Xiamen Ruicheng enforces barcode tracking, full-line parameter logging, and in-process inspection to ensure each batch maintains reliable performance and geometry.A rigid traceability system is essential for stable mass delivery.

- Batch Traceability: Full-process tracking covering material and parameters.

- Parameter Recording: Ensures execution stability.

- Inline Measurement: Detects early deviation trends.

- Batch Mechanical Testing: Verifies consistent strength.

📦 Consistency is achieved through disciplined tracking, inspection, and process monitoring.

Key Factors for Stable Mass Production of Automotive-Grade GF-PA66 Housings

| Category | Process Stability | Mold Consistency | Material Reliability | Batch Delivery |

|---|---|---|---|---|

| Core Focus | Window control | Gate/Cooling | GF ratio control | QC discipline |

| Common Risks | Warpage/Sink | Dimensional drift | Moisture shift | Strength variation |

| Controls | Temp-pressure curve | CAE compensation | Drying & batch control | Trace & inspect |

| Automotive Needs | Repeatable | Long lifespan | Structure-stable | Fully traceable |

Want to shorten your mass-production ramp-up time? Connect with us now through contact us and Xiamen Ruicheng will support your customized solution needs.

What Enables True Mass-Production Stability for Automotive-Grade GF-PA66 Housings?

Stable production requires synergy between materials, molds, equipment, and QC, forming a repeatable production model for long-term delivery. Xiamen Ruicheng uses structural reviews, locked process windows, and automated monitoring to keep consistency across shifts.Standardized manufacturing workflows greatly reduce variation in mass production.Supply-chain upgrades, backup tooling, material alternatives, and process reserves help maintain production even under fluctuations. These foundations enable manufacturers to scale production while ensuring long-term reliability for EV platforms.

1.Material Evaluation: Ensures suitability for real-world environments.

2.Mold Life Management: Prevents batch drift from tool wear.

3.Automation Monitoring: Reduces operator-induced variation.

4.Line Replicability: Ensures cross-batch consistency.

FAQ

1. What are the core quality standards for automotive-grade GF-PA66 battery housings?

Dimensional tolerance ±0.05 mm, stable fiber distribution, and heat-impact performance supported by a controlled molding window and full QC validation.

2. How can I connect with a GF-PA66 housing supplier and request a quotation?

Submit STEP/IGES 3D drawings; Xiamen Ruicheng provides DFM review and quotation within 12 hours, plus optional sample confirmation.

3. What are the MOQ and lead time for GF-PA66 battery housing production?

MOQ starts at 100 pcs for small batches; mass orders scale to tens of thousands. Samples ship in 5–7 days, production in 10–20 days with delivery tracking and backup tooling.

Conclusion

Stable mass production of automotive-grade GF-PA66 battery housings requires integrated control across materials, molds, processes, and QC—not isolated optimization. With its long-term production experience and standardized workflows, Xiamen Ruicheng ensures consistently high-quality housing delivery.System-level production management is the true foundation of stable delivery.Looking ahead, EV suppliers need reliable partners capable of sustained production and scalable performance as battery structures evolve.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!