Injection molding is crucial for nylon processing. However, surface defects such as ripples and silver streaks often plague the industry, affecting aesthetics and performance. In-depth analysis of the causes and effective solutions are essential. This article will focus on materials, molds, and processes to explore solutions to surface problems in injection molded nylon.

To solve the surface problems of nylon injection molding, it is necessary to explore the root causes. The hygroscopicity, flowability, and shrinkage of nylon are key factors. At the same time, poor mold design and improper process parameters can also lead to defects.

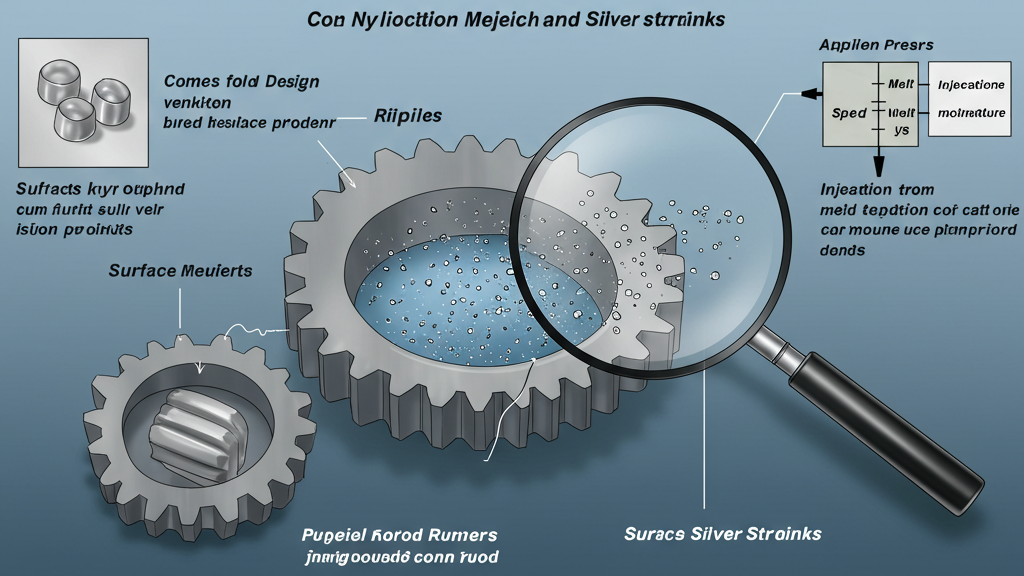

What are the common surface problems in nylon injection molding?

Injection-molded nylon products can exhibit a wide variety of surface defects. Understanding the specific forms of these common problems is the first step in effectively diagnosing and resolving them.

- Ripples: The surface exhibits linear or wavy traces, commonly found at melt confluence points.

- Orange Peel: The surface is covered with tiny pits, with a rough texture similar to orange peel.

- Silver Streaks: Slender, silvery-white streaks appear on the surface, often distributed along the melt flow direction.

- Cracks: Linear fractures or fissures exist on the surface or inside the product.

What are the main causes of surface problems?

Various factors contribute to the generation of surface defects in injection-molded nylon products. In-depth analysis of these root causes is a key prerequisite for developing effective prevention and control measures.

- Material Properties: The inherent characteristics of nylon, such as hygroscopicity and flowability, can affect surface quality.

- Mold Design: Unreasonable feed system, and venting, and other mold defects are important causes of surface problems.

- Process Parameters: Improper process settings, such as injection pressure, temperature, and speed, directly affect surface quality.

- Operating Environment: Factors such as raw material contamination and non-standard operations can also lead to surface problems.

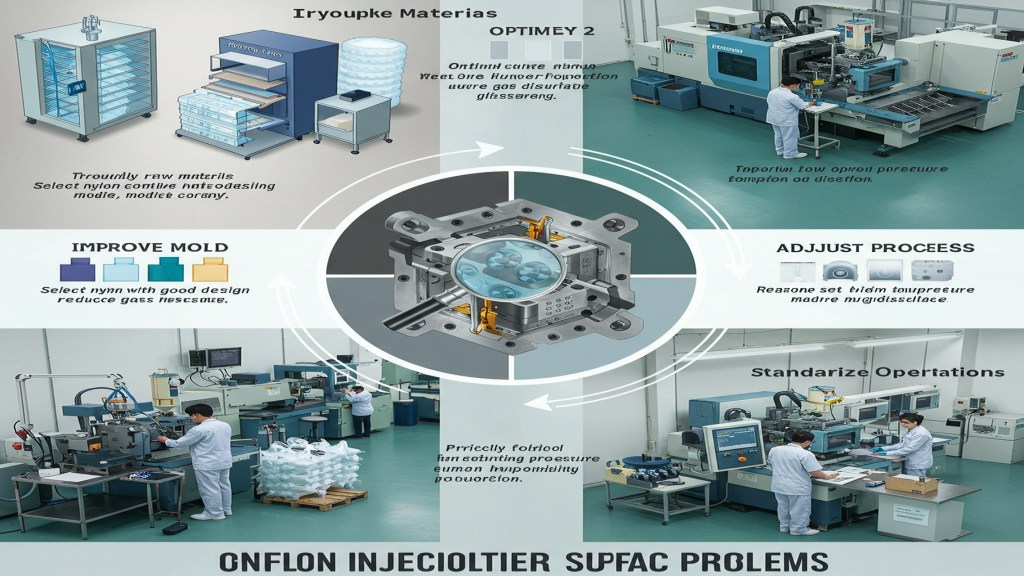

What are the effective solutions?

Solving surface problems in injection molded nylon requires targeted strategies. Understanding the causes of different defects is a prerequisite for choosing effective methods, enabling improvements from multiple aspects, including materials, molds, and processes.

- Optimize Materials: Thoroughly dry the raw materials, select nylon with good flowability, and modify it if necessary.

- Improve Mold: Optimize the feed and venting system, and regularly maintain the surface finish of the mold.

- Adjust Process: Finely adjust key parameters such as injection pressure, temperature, and speed.

- Standardize Operations: Strictly implement operating procedures, control environmental humidity, and standardize demolding.

Summary of nylon surface lifting

| Influencing Factors | Common Issues | Recommended Improvement Strategies | Precautions |

|---|---|---|---|

| Raw Material Management | Excessive Moisture, Impurities, Batch Instability | Strict Drying Process, Establish Raw Material Inspection System, Select Qualified Suppliers, Implement FIFO Principle | Ensure Good Performance of Drying Equipment, Regularly Calibrate Testing Instruments, Establish a Sound Traceability System |

| Mold Design | Uneven Cooling, High Runner Resistance, Poor Venting | Optimize Cooling Channel Design, Enlarge Runner Cross-sectional Area, Add Effective Venting Grooves/Pins, Consider Hot Runner System | Mold Processing Accuracy is Crucial, Regularly Clean and Maintain Cooling Channels, Venting Effectiveness Needs Mold Trial Verification |

| Injection Molding Process | Insufficient Holding Pressure, Fluctuating Injection Speed, Inaccurate Temperature Control | Extend Holding Time, Optimize Injection Speed Profile, Precisely Control Melt and Mold Temperature, Adopt Closed-loop Control System | Parameter Adjustment Should Be Gradual, Consider Material Properties and Mold Structure, Record and Analyze the Impact of Process Parameter Changes on Quality |

| Equipment Maintenance | Decreased Injection Molding Machine Performance, Screw Wear | Regularly Maintain Injection Molding Machine, Inspect and Replace Worn Parts (e.g., Screw, Barrel), Ensure Stable Hydraulic System | Establish a Sound Equipment Maintenance System, Operators Should Be Proficient in Equipment Performance, Regularly Perform Equipment Accuracy Testing and Calibration |

| Environmental Control | Excessive Workshop Humidity, Dust Contamination | Control Workshop Humidity Within a Reasonable Range, Implement Effective Dust Removal Measures, Keep Production Area Clean | Humidity Control Needs to Consider Seasonal Changes, Dust Removal Equipment Needs Regular Maintenance, Strengthen Personnel Hygiene Management |

| Post-processing | Concentrated Internal Stress, Surface Scratches | Consider Annealing or Tempering and Other Post-processing Techniques, Standardize Product Handling and Packaging Processes, Adopt Appropriate Surface Protection Measures (e.g., Protective Film) | Post-processing Parameters Need to Be Determined Based on Material and Product Characteristics, Handle with Care During Transportation, Packaging Materials Should Avoid Causing Secondary Damage to the Surface |

Prevention, Control, and Quality Improvement

Improving the quality of injection-molded nylon products and preventing and controlling surface problems is not just an isolated application of a single strategy. It requires comprehensive consideration and organic integration. Strengthening equipment maintenance and environmental control provides a stable and reliable guarantee for production. Ultimately, by establishing a sound quality monitoring system to strictly inspect the production process and final products, and by promptly identifying and resolving problems, we can effectively prevent and control surface defects in injection-molded nylon, thereby comprehensively improving product quality and production efficiency.

1.Full-Process Quality Control: Establish a sound quality management system to strictly control every production stage.

2.Standardized Operations: Promote standardized operating procedures and systematic training to reduce human-induced quality fluctuations.

3.Data-Driven Monitoring: Implement data acquisition and analysis to monitor process parameters and quality data in real-time.

4.Cross-Department Collaboration: Strengthen interdepartmental collaboration and continuous improvement to jointly enhance product quality and efficiency.

Conclusion

Addressing surface problems in injection-molded nylon requires a systematic approach. Common defects, such as ripples and pock marks, stem from materials, molds, and processes. Targeted strategies include optimizing materials, improving molds, and adjusting process parameters. A full-process quality control system should be established, standardized operations should be promoted, data-driven monitoring should be utilized, and cross-departmental collaboration should be fostered. By comprehensively applying these methods, surface problems can be effectively prevented and controlled, ultimately improving product quality.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!