Introduction

Injection molding of complex structures often faces sink mark issues due to uneven wall thickness, inconsistent cooling rates, and intricate flow paths. Sink marks not only affect surface appearance but can also compromise mechanical strength, leading to product reliability concerns. Therefore, preventive measures during the design and molding stages are essential.

We minimize sink mark occurrence through optimized runner design, precise pressure control, and the use of high thermal conductivity mold materials. Scientific process management ensures balanced filling and cooling, effectively preventing localized volume shrinkage.

What Are the Main Causes of Sink Marks in Complex Structures?

Complex geometries often feature multiple thick sections and irregular flow paths that create internal stress and temperature gradients. This structural complexity leads to uneven shrinkage and localized voids or surface depressions. Understanding material flow behavior and synchronized cooling is key to reducing sink marks in production.

- Flow Path Control: Ensures even melt flow and minimizes stagnation zones.

- Material Optimization: Selects low-shrinkage, thermally stable engineering plastics.

- Holding Phase Adjustment: Extends holding time to fully compensate for material shrinkage.

- Cooling Channel Design: Manages temperature uniformity across mold zones, reducing stress buildup.

😊 Understanding the cause of sink marks is the first step toward solving complex molding challenges.

How Can Process Optimization Reduce Sink Marks?

In complex injection molding, fine-tuning process parameters often determines part density and quality. Controlling injection speed, holding time, and mold temperature is the key to preventing sink marks. Improper injection speed or unbalanced cooling can interrupt material flow or create insufficient packing.

- Injection Speed Control: Moderate speeds help avoid premature solidification and flow dead zones.

- Holding Pressure and Time: Maintains continuous material compensation during shrinkage.

- Cooling Rate Matching: Uses zone-based cooling to ensure uniform temperature reduction.

- Mold Venting Design: Removes trapped gases to avoid voids and burn marks.

💡 Fine-tuning parameters is the core of solving sink mark issues.

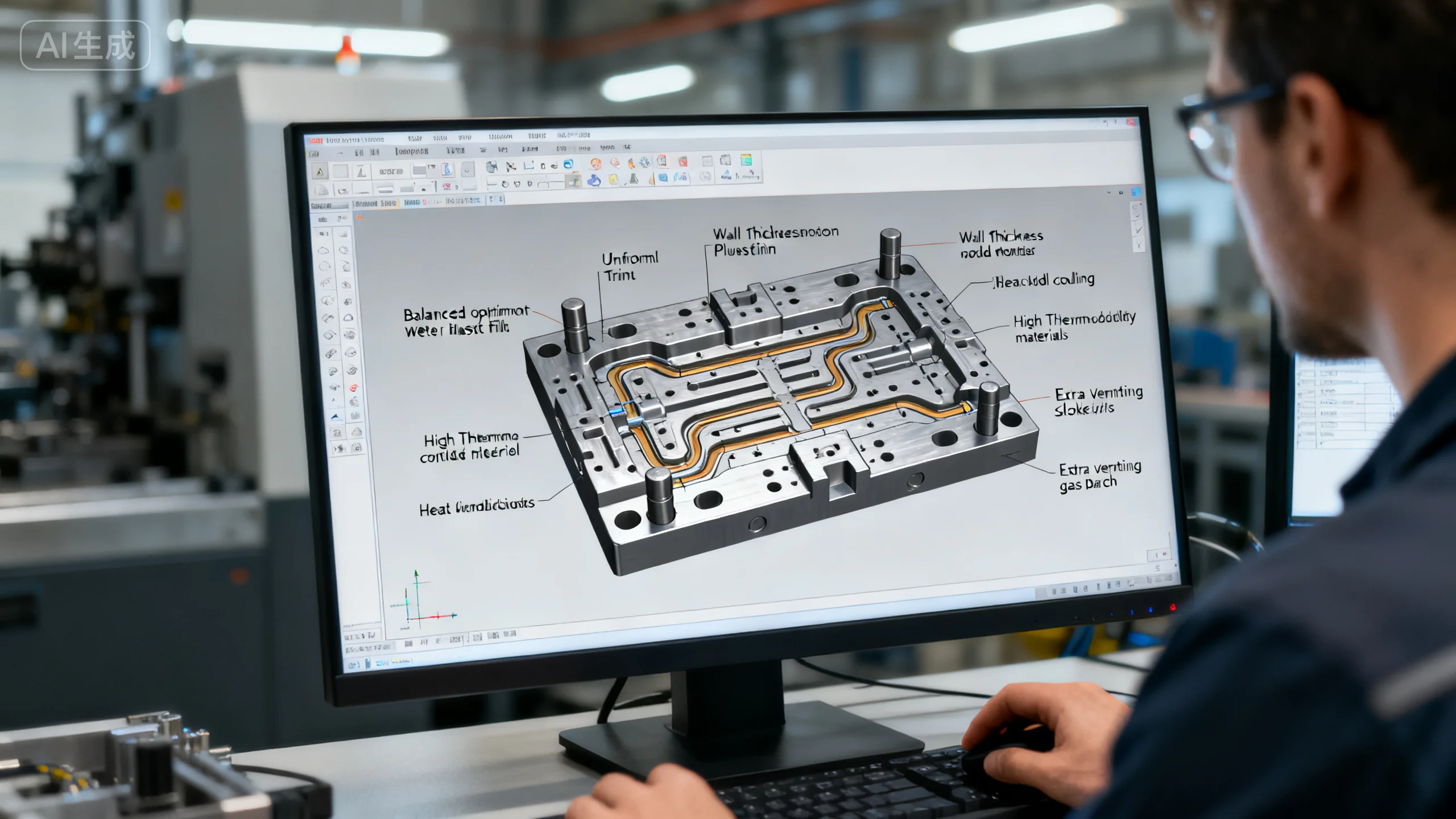

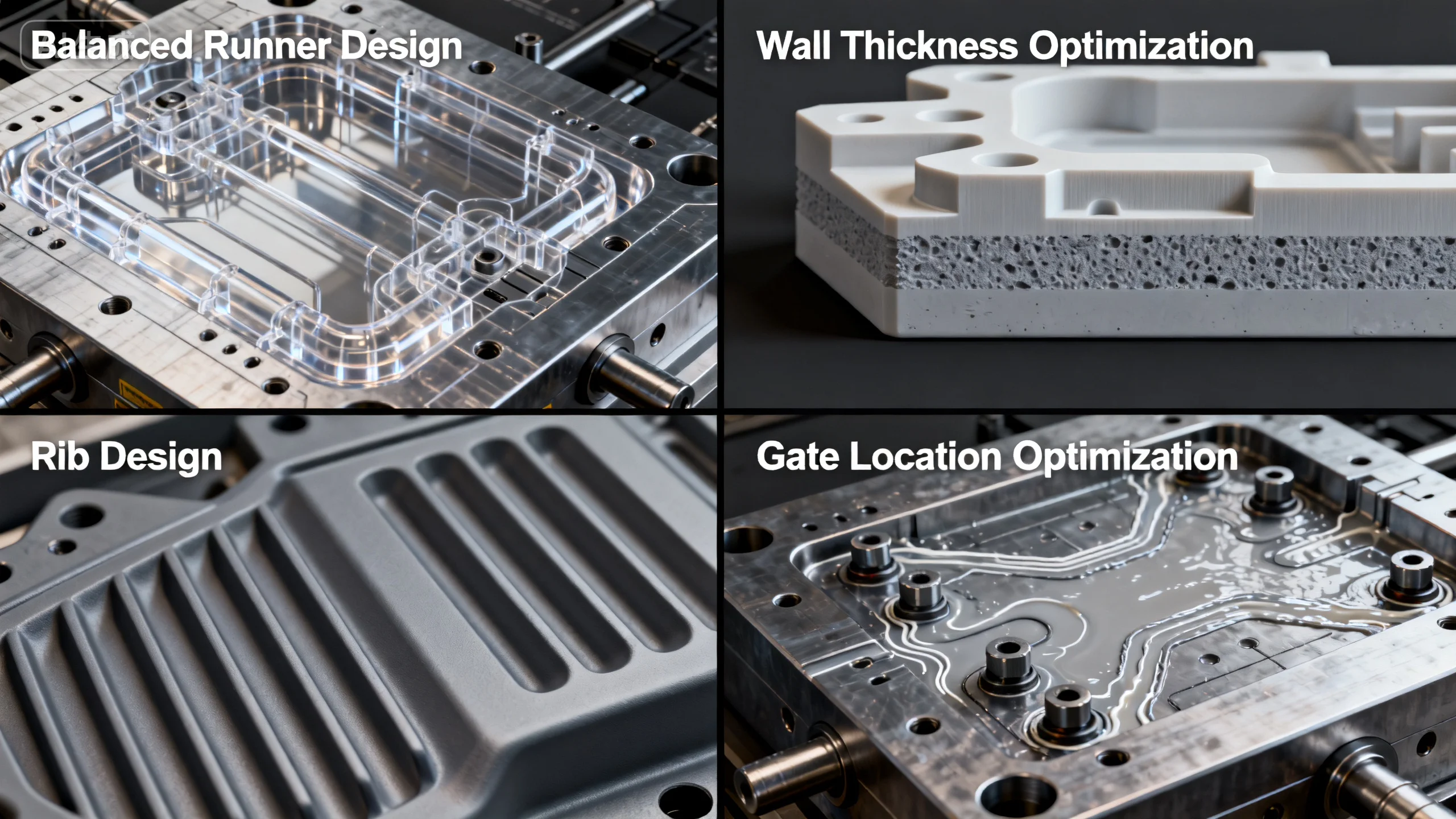

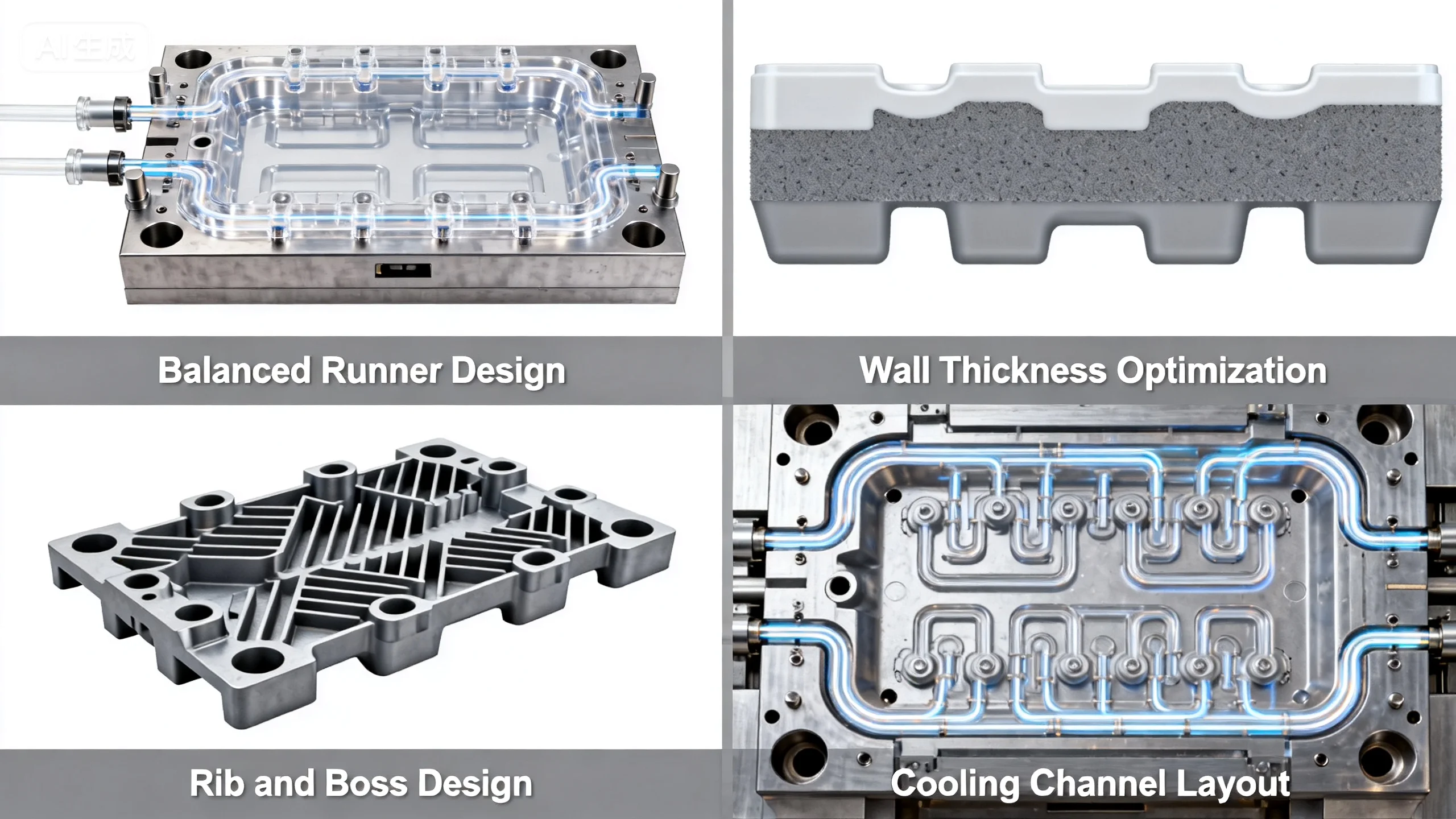

What Design Strategies Can Prevent Sink Marks from the Source?

Mold design plays a decisive role in avoiding sink marks for complex components. Uniform wall thickness, strategic packing zones, and adjustable cooling systems can eliminate early-stage shrinkage risks. Optimizing runner layout and gate positions based on flow simulation ensures even melt distribution.

- Balanced Runner Design: Minimizes flow path differences and ensures uniform filling.

- Wall Thickness Optimization: Prevents uneven cooling between thick and thin sections.

- High-Conductivity Mold Materials: Improves heat transfer and shortens cycle time.

- Additional Venting Slots: Removes trapped air to avoid local depressions.

🧩 Preventing sink marks from the design stage is the most effective stability strategy.

Sink Mark Control in Different Molding Methods

| Comparison Item | Standard Molding | High-Holding Molding | Zoned Cooling Molding | Smart Thermal Mold |

|---|---|---|---|---|

| Sink Mark Probability | High | Medium | Low | Very Low |

| Surface Flatness | Fair | Good | Excellent | Excellent |

| Mold Cost | Low | Medium | High | Higher |

| Production Efficiency | High | Medium | Medium | High |

The key to competitive complex molded parts lies in controllable quality and density. We provide tailored anti-sink-mark molding solutions for your complex designs. 👉 contact us

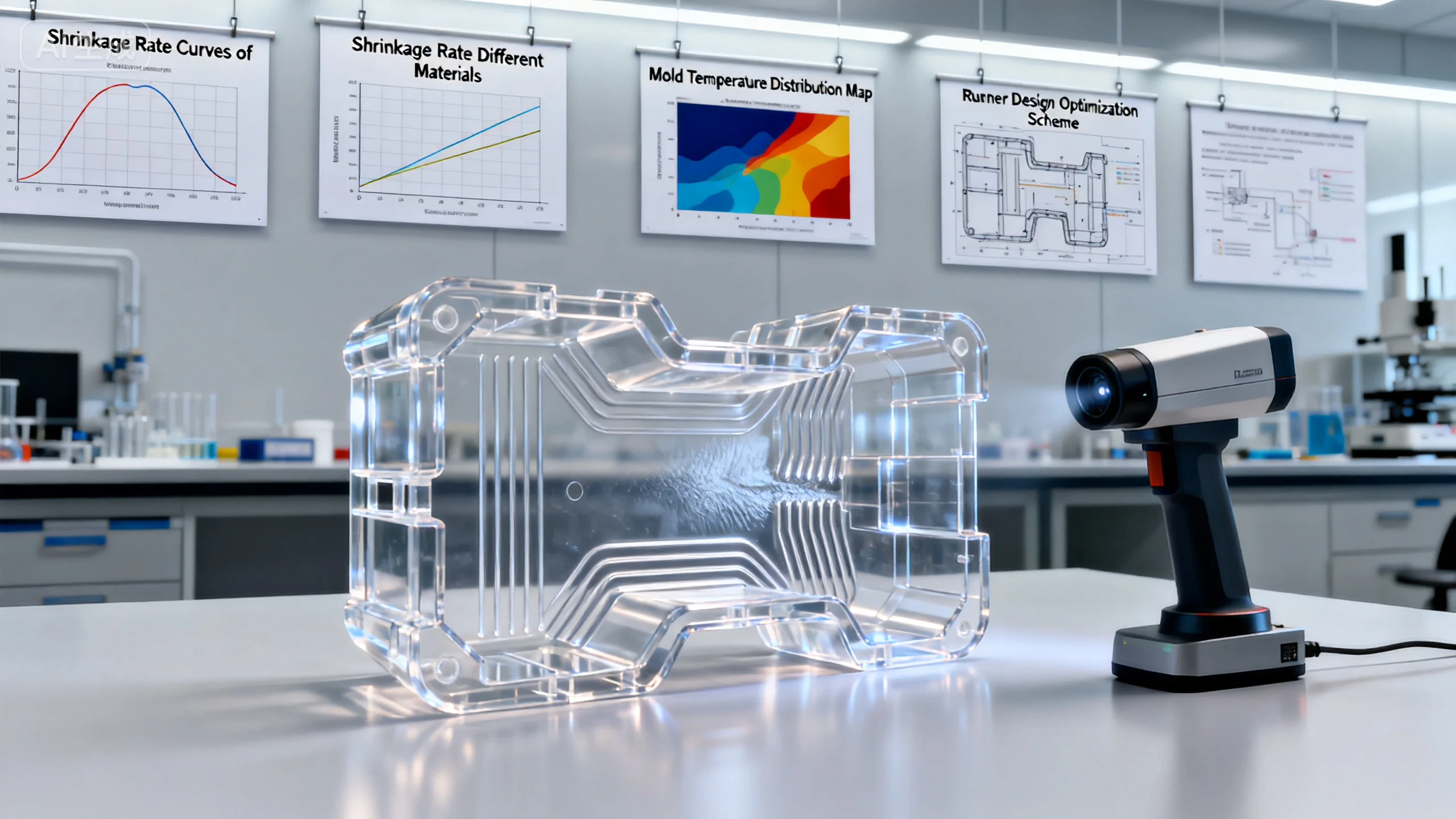

How Smart Molding Monitoring Improves Sink Mark Control

Through real-time data collection and closed-loop control, smart injection molding can automatically adjust process parameters for consistent quality. Monitoring pressure, temperature, and flow rate helps detect potential sink mark risks in advance. The system can modify holding curves dynamically to ensure uniform density.

1.AI Quality Prediction: Uses machine learning to predict sink mark risks.

2.Dynamic Parameter Control: Automatically adjusts temperature and pressure.

3.Process Traceability: Records every cycle for data-driven improvement.

4.Adaptive Cooling: Adjusts coolant flow based on thermal field mapping.

Conclusion

Sink marks in complex structures require coordinated optimization of design, materials, and process. By managing flow, cooling, and holding pressure scientifically, manufacturers can eliminate shrinkage defects at the root. Integrating smart monitoring enhances molding stability and repeatability, ensuring both aesthetic and structural excellence in every part.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!