Introduction

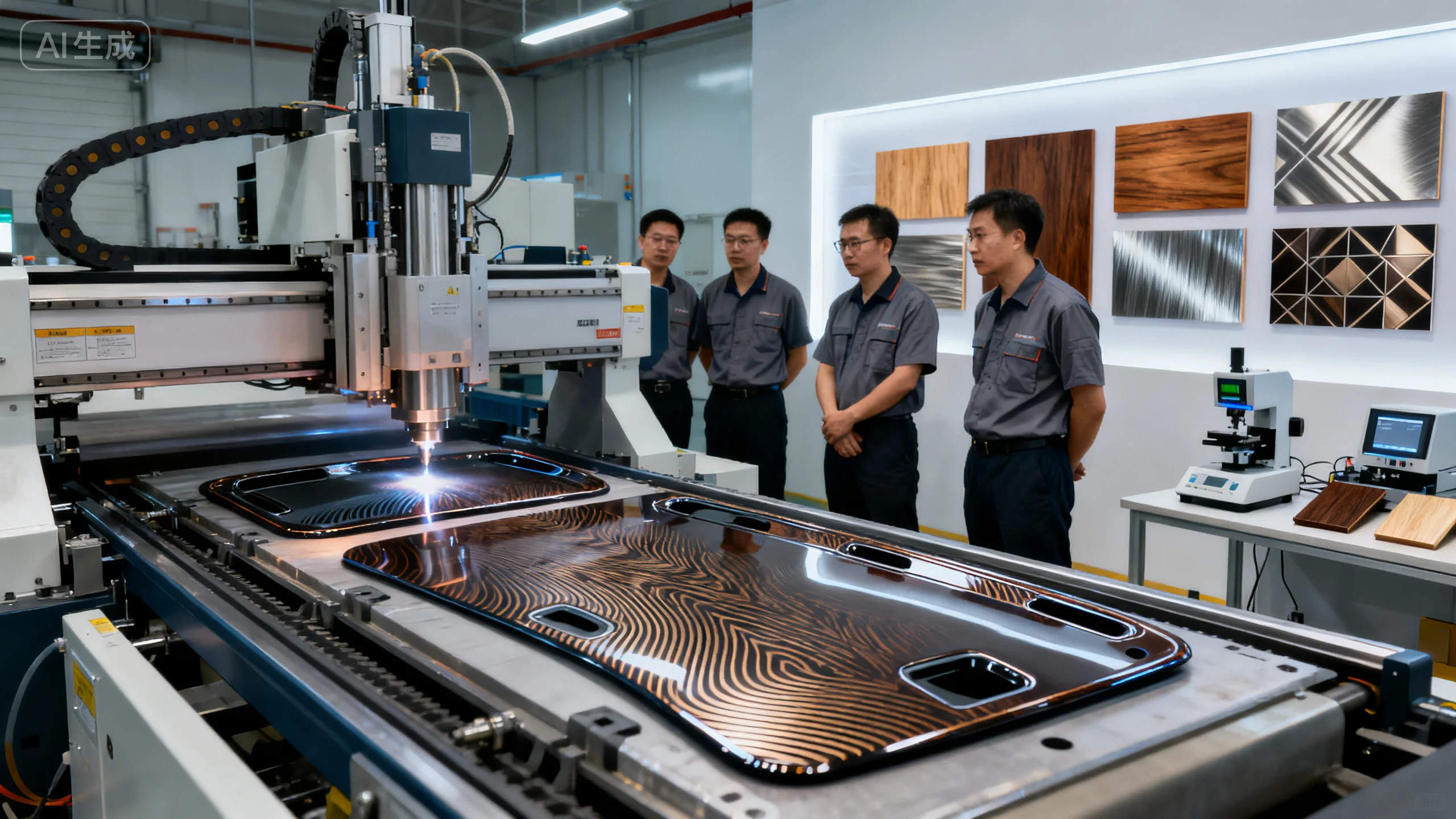

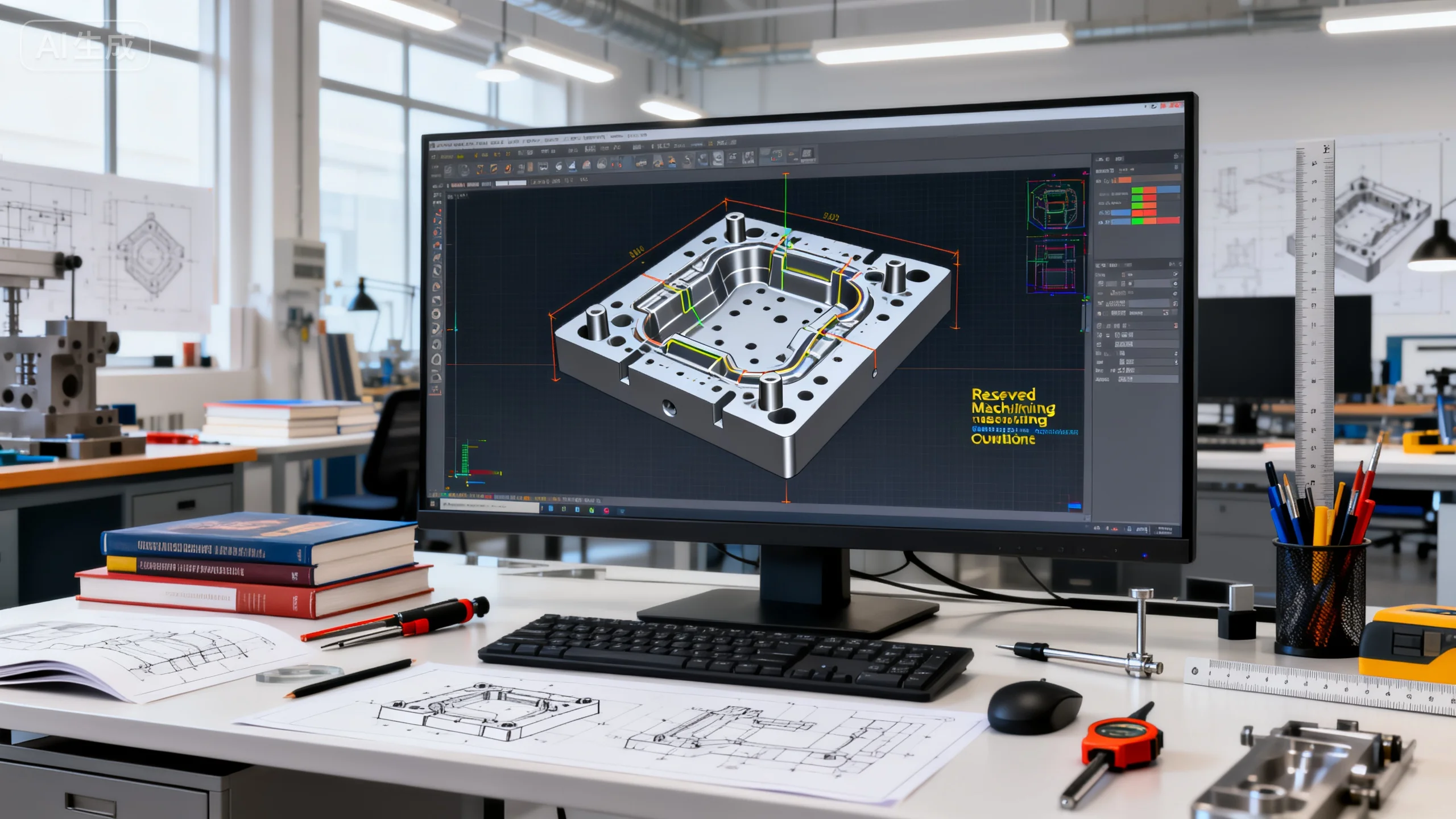

In modern injection molding, pre-designed allowances are not only a key factor in cost reduction but also a cornerstone for optimizing production rhythm. By reserving machining spaces during the mold design stage, manufacturers can effectively minimize secondary operations like CNC machining and drilling. This proactive approach enhances automation and consistency across mass production.

At the same time, well-planned allowances ensure assembly compatibility and dimensional precision, reducing the need for manual rework or adjustment. This not only lowers labor dependency but also significantly improves product yield and quality stability.

How to achieve proper allowance design at the mold stage?

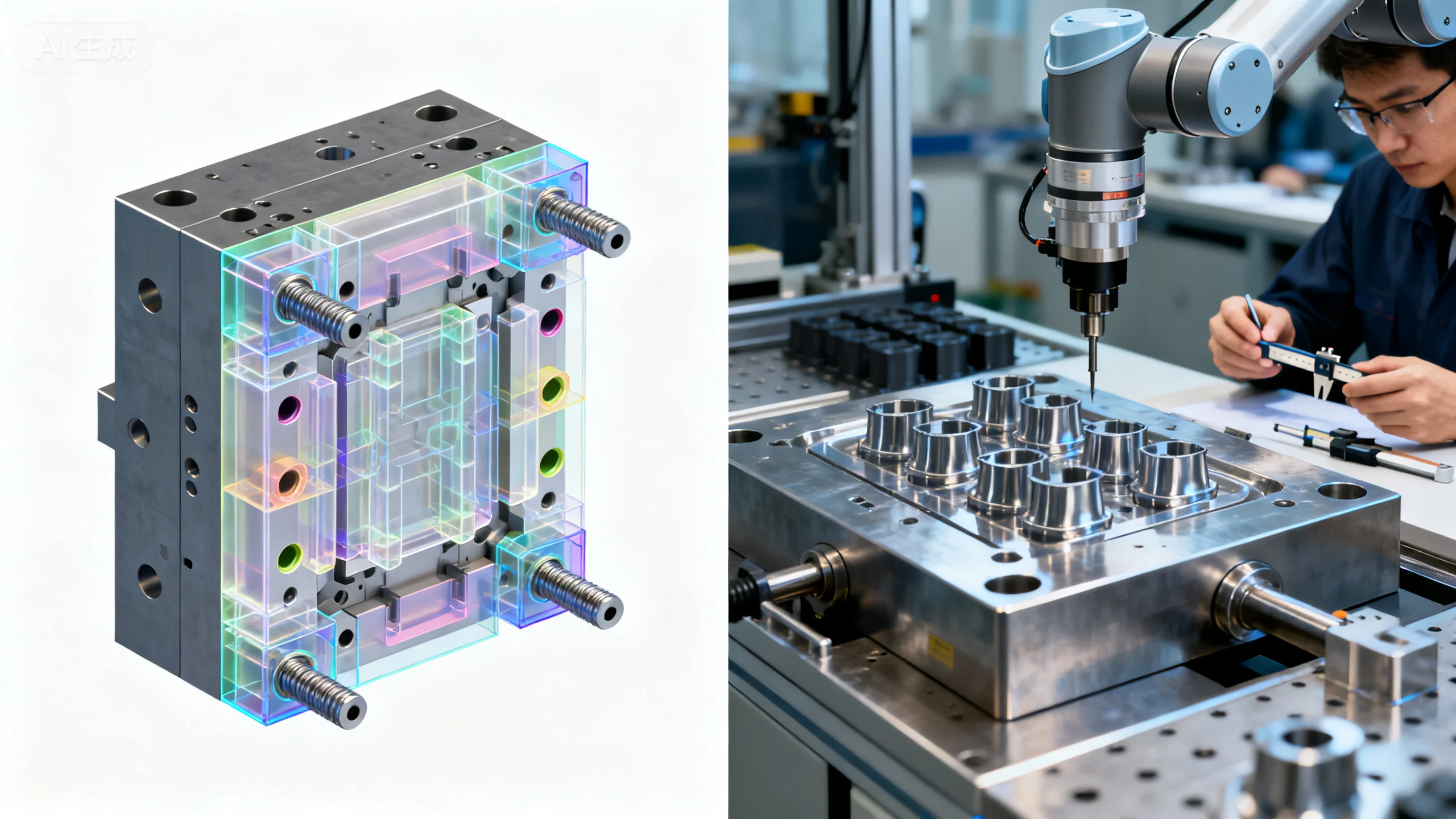

In mold design, the distribution of allowance areas directly affects the complexity of post-processing. By reserving machining tolerances at critical holes, bosses, or locating surfaces, secondary finishing becomes more efficient. This “design-first” mindset shortens machining paths and minimizes accumulated errors.

- CAD Modeling Optimization: Define allowance zones early in the CAD environment to enhance mold precision.

- Allowance Control: Use data simulation to determine optimal material margins and avoid overcutting.

- Mold Maintainability: Incorporate modular structures to facilitate secondary machining or adjustments.

- Process Simulation: Validate molding flow behavior beforehand to reduce later-stage corrections.

💡 Smart allowances lead to less machining and higher dimensional precision.

Which allowance structures reduce post-processing costs the most?

Typical molded parts like electronic housings, automotive components, and mechanical brackets often require post-machining such as drilling or threading. By adding insert seats, open channels, or guide grooves in the mold, these secondary operations can be minimized. This reduces machining cycles and prevents stress concentration or deformation.

- Insert Molding: Integrates metal and plastic in one molding cycle, eliminating drilling steps.

- Positioning Features: Built-in alignment aids improve assembly accuracy.

- Reinforcement Allowances: Reduce the need for post-added structural supports.

- Preformed Hole Design: Mold-in holes directly instead of manual drilling.

🧩 Optimized allowances mean every skipped step saves time and money.

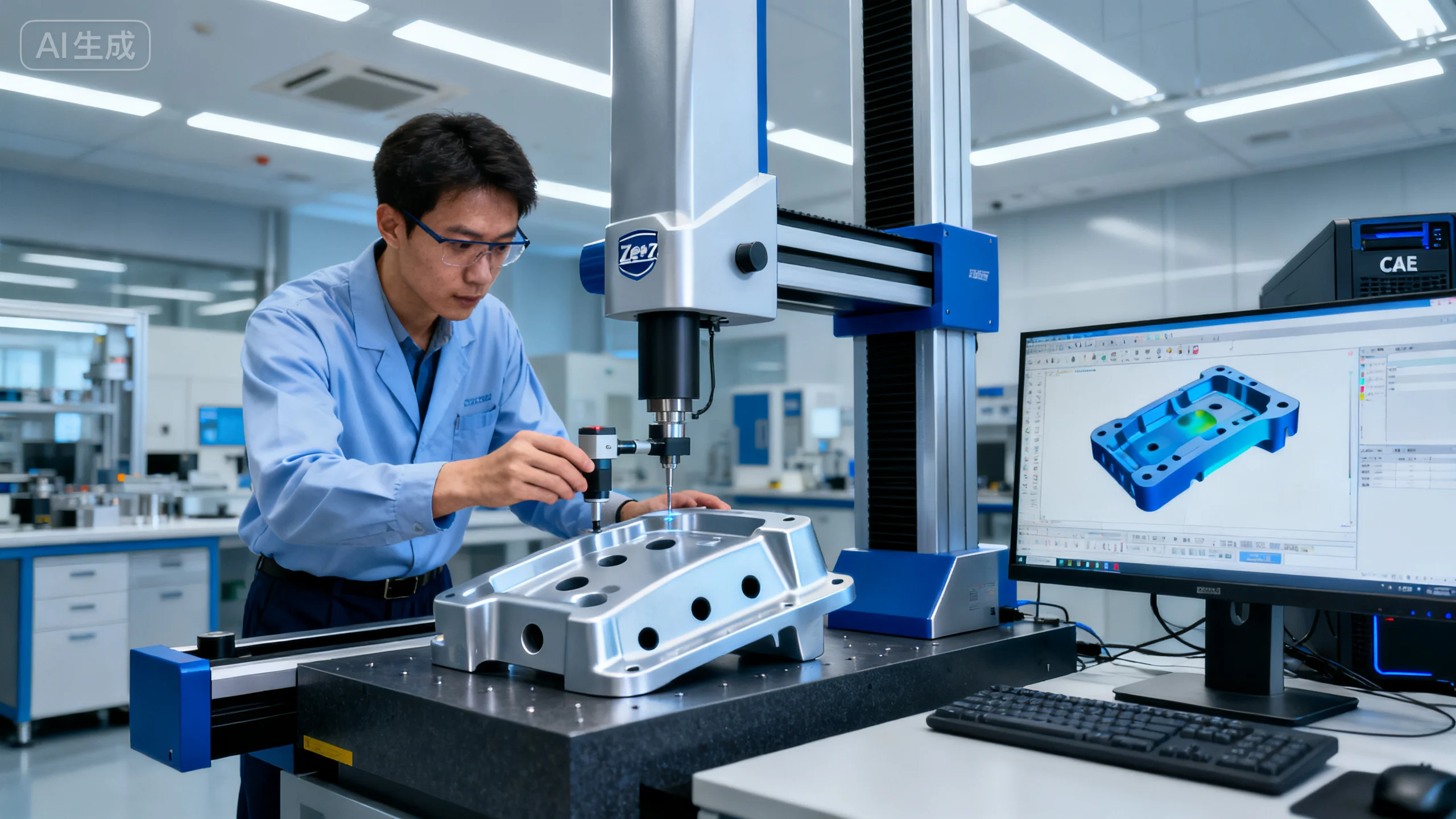

How to ensure dimensional accuracy after secondary machining?

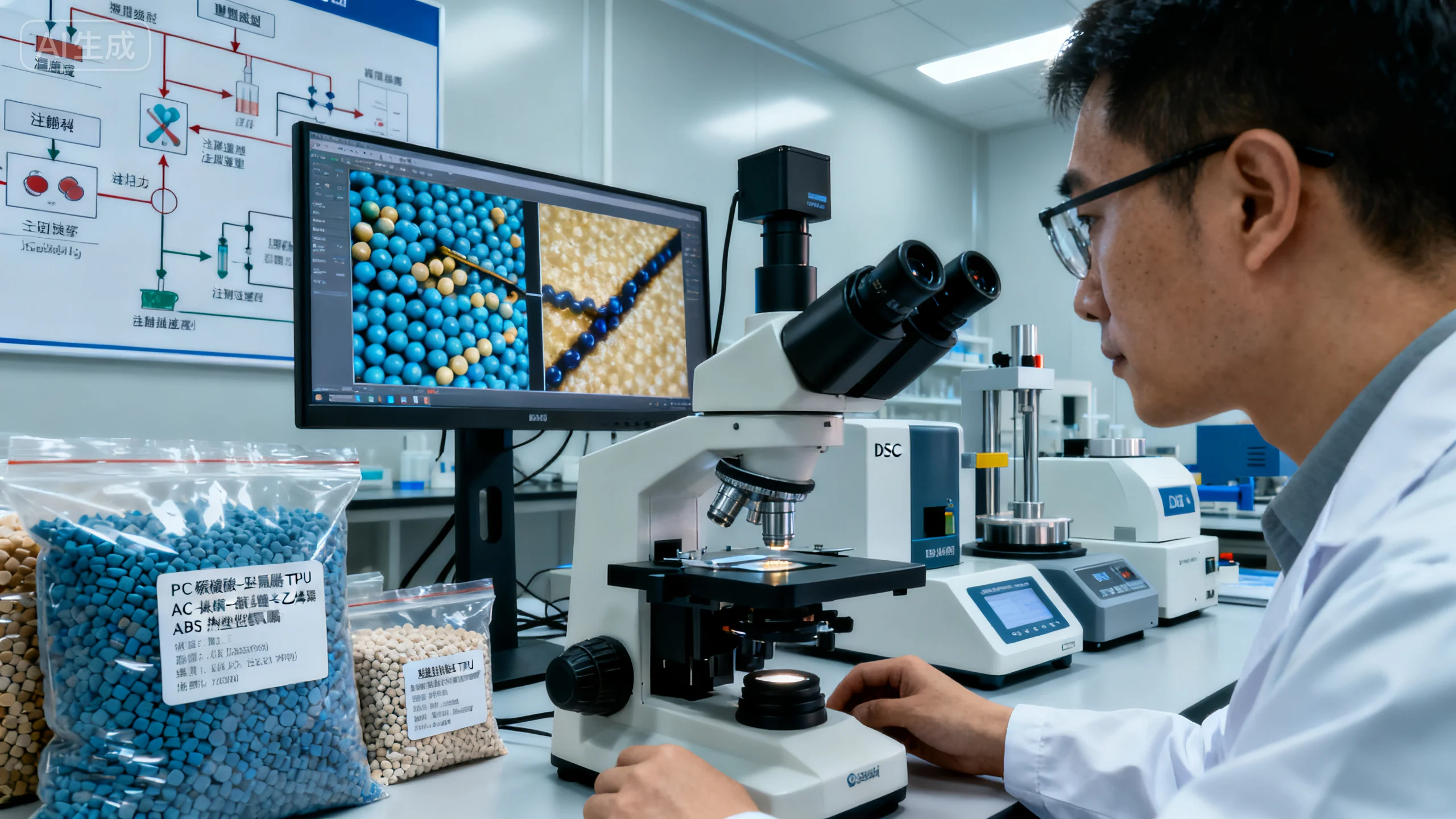

Dimensional accuracy in allowance-based injection molding depends on shrinkage compensation and mold precision. Designers must anticipate material behavior during flow and cooling to ensure machining reference surfaces remain consistent. Only by predicting deviations early can secondary processing achieve zero-tolerance outcomes.

- Shrinkage Compensation: Use CAE software to forecast material shrinkage and adjust allowance geometry.

- Precision Fixture Design: Employ high-accuracy jigs to stabilize machining positions.

- Thermal & Cooling Control: Manage temperature gradients to prevent deformation.

- Inline Inspection: Continuously monitor dimensions to ensure consistency after machining.

📏 Precision forecasting is the key to seamless secondary integration.

Comparison of Allowance Strategies and Post-Processing Complexity

| Strategy Type | Allowance Approach | Machining Steps | Dimensional Stability | Cost Trend | Cycle Time | Best Use Case |

|---|---|---|---|---|---|---|

| No Allowance | None | Multiple | Fluctuating | ↑ | Long | Basic Parts |

| Partial Allowance | Boss/Hole Zones | -30% | Stable | ↓ | Medium | Structural Parts |

| Full Allowance | Key Surfaces | -60% | Consistent | ↓↓ | Short | Enclosures |

| Insert Integration | Metal Inserts | -80% | Excellent | ↓↓↓ | Shortest | Automotive Components |

💬 Want to explore how optimized allowances can streamline your mold design? contact us.

The Role of Allowances in Automated Assembly

With automation becoming the new norm, allowance design has become crucial for robotic assembly and inline inspection. By precisely defining geometric interfaces during mold design, manufacturers can ensure smoother integration into automated workflows. This forward-thinking approach empowers companies to transition toward smart manufacturing.

1.Robotic Compatibility: Allocate pick-up and alignment spaces.

2.Modular Interface Design: Reduce equipment setup time.

3.Inspection Points Pre-Defined: Simplify dimensional validation.

4.Smart Feedback Loops: Enable data-driven process improvements.

Conclusion

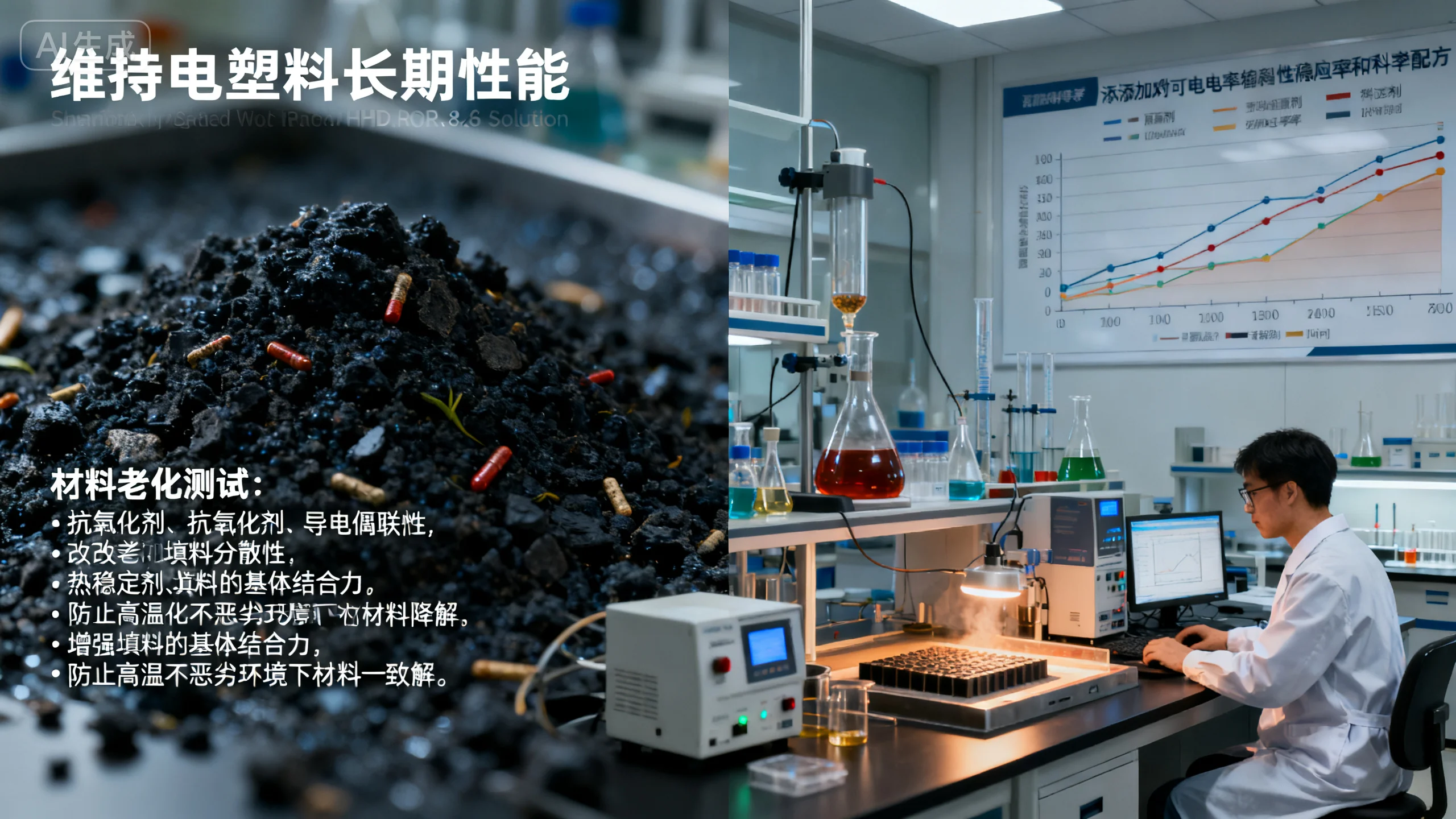

Implementing smart allowances during injection molding not only simplifies secondary processing but also enhances tool longevity and part uniformity. It shifts the traditional “fix it later” mindset into a “design it right first” approach, driving the transition toward digital manufacturing.Optimized allowance design isn’t just a cost-saving measure — it’s a competitive edge that defines the future of efficient, precise, and intelligent production.

For expert assistance in implementing injection molding optimization for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!