Polycarbonate (PC) lenses exhibit excellent performance, but injection molding tends to generate internal stress, which acts as a latent defect, affecting optical performance and lifespan, and even leading to cracking. Therefore, effectively reducing internal stress in PC lenses is crucial for enhancing product quality.

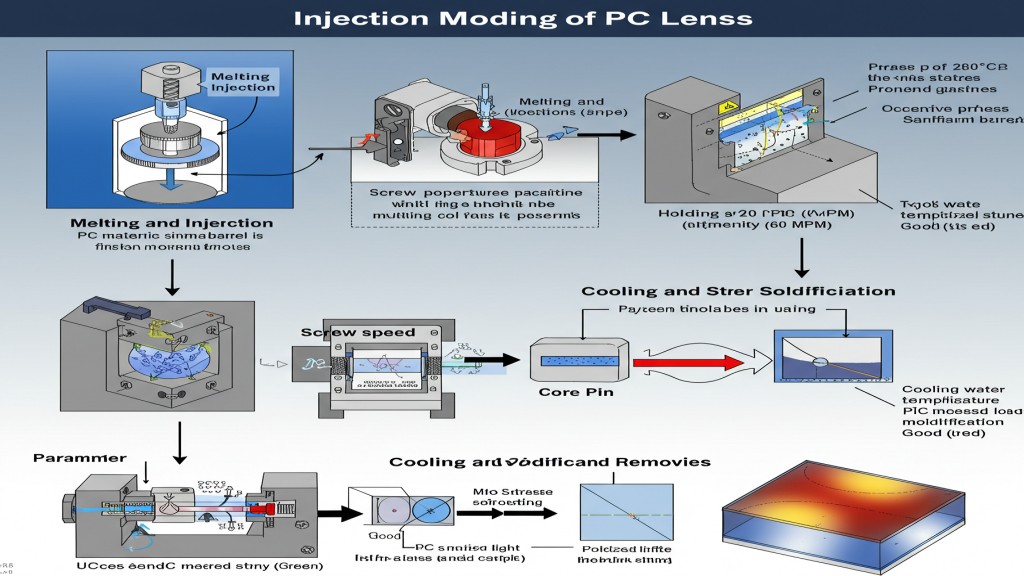

Which injection molding stages are key to the generation of internal stress? What methods can be used to suppress it at the source or release it in the later stages? Next, we will focus on core steps such as injection, holding pressure, cooling, and demolding, and explore optimization schemes to obtain low-internal-stress, high-quality PC lenses.

Which injection molding parameters significantly affect internal stress in PC lenses?

The superior performance of polycarbonate lenses makes them widely used. However, the generation of internal stress during injection molding is a critical factor affecting their final quality. Investigating which core injection molding parameters play a leading role in the formation of internal stress is a prerequisite for achieving high-quality PC lenses.

- Melt Temperature: Inappropriate melt temperature can trigger uneven flow and differences in molecular orientation, thereby exacerbating internal stress.

- Injection Speed: Injection speeds that are too fast or too slow are not conducive to uniform cooling and filling, leading to internal stress problems.

- Holding Pressure and Time: Improper holding pressure and time can excessively affect molecular orientation and shrinkage, increasing internal stress.

- Mold Temperature: Non-uniformity in mold temperature directly leads to differences in cooling rates, generating significant thermal stress.

Which Process Optimization Strategies Can Reduce Internal Stress?

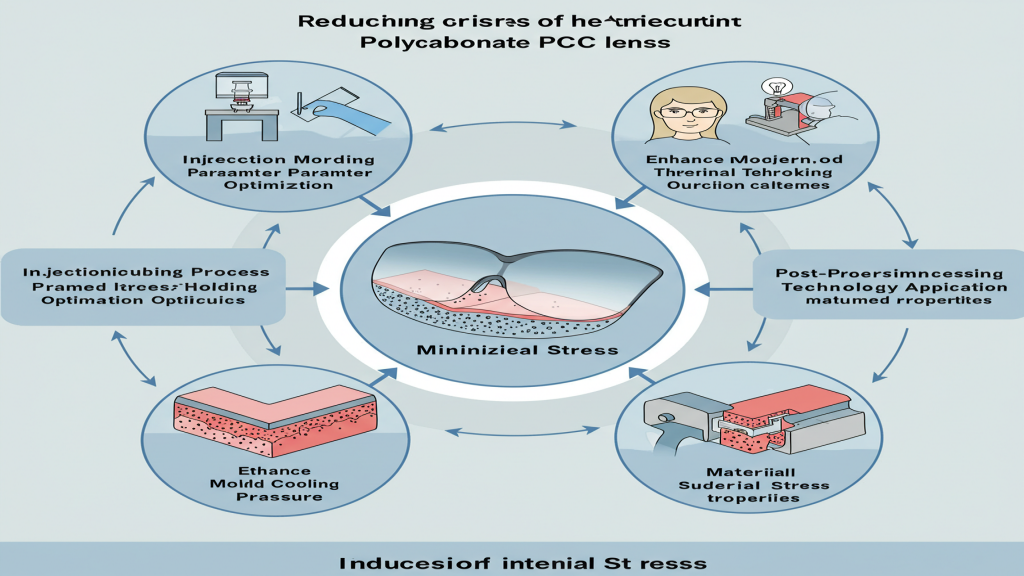

After recognizing the impact of key injection molding parameters on internal stress in polycarbonate lenses, the next step is to explore effective process optimization strategies. By finely controlling various aspects of the injection molding process, we can significantly reduce or even eliminate residual stress within the lenses, thereby improving the overall performance and reliability of the product.

- Precisely Control Melt Temperature: Employ a suitable melt temperature range to ensure uniform flow and reduce differences in molecular orientation.

- Optimize Injection Speed Profile: Implement segmented injection to achieve smooth filling and avoid excessive shear and orientation.

- Reasonably Set Holding Pressure Parameters: Adjust holding pressure and time according to the product and mold to achieve sufficient compensation for shrinkage and avoid over-stretching.

- Maintain Uniform Mold Temperature: Ensure that the mold temperature is stable and uniform to prevent thermal stress caused by differences in cooling rates.

What Additional Methods or Post-Treatments Can Release Stress?

In addition to optimizing process parameters during injection molding, we can also use some auxiliary methods or post-treatment techniques to further release and relieve internal stress in already molded polycarbonate lenses. These methods can improve the molecular structure of the material from different levels, ultimately enhancing the overall performance of the lenses.

- Annealing: By heating and holding at a specific temperature, followed by slow cooling, PC molecular chains are relaxed, reducing orientation stress.

- Thermal Conditioning: Employing specific heating and cooling programs promotes molecular chain rearrangement, releasing internal stress and improving performance.

- Chemical Annealing: Treating the lens surface with specific chemicals relaxes the surface molecular chains to reduce overall internal stress.

- Vibration Stress Relief: By applying mechanical vibration, internal movement of the material is promoted, accelerating the release of internal stress.

Injection molding process and post-treatment method

| Methods to Reduce Internal Stress | Specific Measures |

|---|---|

| Optimize Melt Temperature | Adopt the recommended temperature range for uniform flow. |

| Optimize Injection Speed | Implement multi-stage injection for smooth filling and avoiding excessive shear. |

| Reasonable Holding Parameters | Adjust pressure and time according to the product and mold to avoid over-stretching. |

| Uniform Mold Temperature | Maintain a stable and uniform mold temperature to avoid uneven cooling. |

Measures to Optimize Internal Stress

Recognizing that multiple factors during injection molding can lead to internal stress in polycarbonate lenses, we will focus on how to effectively reduce these adverse effects through refined control of process parameters and the rational application of post-treatment techniques. The following measures are designed to provide specific practical guidance for producing high-quality, low-stress PC lenses.

1.Optimize Injection Molding Process Parameters: Precisely control key injection molding parameters to ensure uniform melt flow and cooling, in order to reduce internal stress.

2.Adopt a Reasonable Mold Design: Optimize the feed system and cooling system to achieve uniform filling and cooling, reducing stress generation.

3.Implement Effective Post-Treatment Processes: Promote molecular chain relaxation and release internal stress within the lenses through annealing or thermal conditioning.

4.Select the Appropriate PC Material Grade: Choose PC materials with lower internal stress sensitivity to reduce stress at the source.

Conclusion

In summary, reducing internal stress in polycarbonate lenses is a systematic project involving multiple factors such as optimization of injection molding process parameters, improvement of mold design, application of post-treatment techniques, and material selection. By precisely controlling melt temperature, injection speed, holding pressure and time, and mold temperature, the generation of internal stress during the molding process can be significantly reduced.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!