Packaging is a crucial aspect of modern industry, where rapid mass production is paramount. Polypropylene (PP), due to its excellent properties and cost-effectiveness, has become a common material in the packaging field. Injection molding technology, with its high efficiency, is perfectly combined with polypropylene and serves as the core method for achieving rapid mass production of packaging. This article will focus on the advantages and key technologies of polypropylene injection molding in rapid mass packaging production.

Polypropylene and injection molding processes are crucial in packaging production. So, how does polypropylene injection molding achieve rapid mass production while ensuring quality? This is attributed to the synergy of precision molds, advanced equipment, optimized processes, and automated workflows. Next, we will delve into these core elements to reveal the technical system of polypropylene injection molding for efficient packaging production.

How does PP material adapt to rapid injection molding production?

Polypropylene (PP), as an important thermoplastic resin, possesses a series of unique physical and chemical properties that are highly compatible with the requirements of injection molding processes, laying a solid foundation for the rapid mass production of packaging. It is these inherent material advantages that allow polypropylene to exhibit excellent moldability and production efficiency in an efficient injection molding process.

- Excellent Flowability: Molten PP has good flowability, which allows it to quickly fill complex molds and shorten the molding cycle.

- Rapid Cooling and Solidification: PP crystallizes quickly, allowing the product to solidify rapidly and accelerate the production pace.

- Good Demoldability: PP injection molded parts are easy to demold, reducing resistance and ensuring smooth production.

- Wide Modification Adaptability: PP is flexible in modification, which can optimize processing performance and improve production efficiency.

How does injection molding process optimization speed up packaging production?

In the injection molding process of polypropylene packaging, a series of key technologies and refined process optimization are the core drivers for achieving significant improvements in production efficiency. By precisely controlling injection parameters, optimizing mold design, and employing advanced auxiliary technologies, production cycles can be significantly shortened, and output per unit time can be increased.

- Adopting Hot Runner System: Hot runners can maintain the melt temperature, shorten the cycle, reduce waste, and improve efficiency.

- Optimizing Mold Design: Multi-cavity, fast cooling, and efficient venting molds can increase single-cycle output and production stability.

- Precisely Controlling Injection Parameters: Precise adjustment of injection parameters ensures fast and high-quality filling, shortening the cycle.

- Applying Quick Mold Change and Automation: Quick mold changes shorten downtime, and automation reduces manual labor, improving efficiency.

What is the role of advanced equipment and molds?

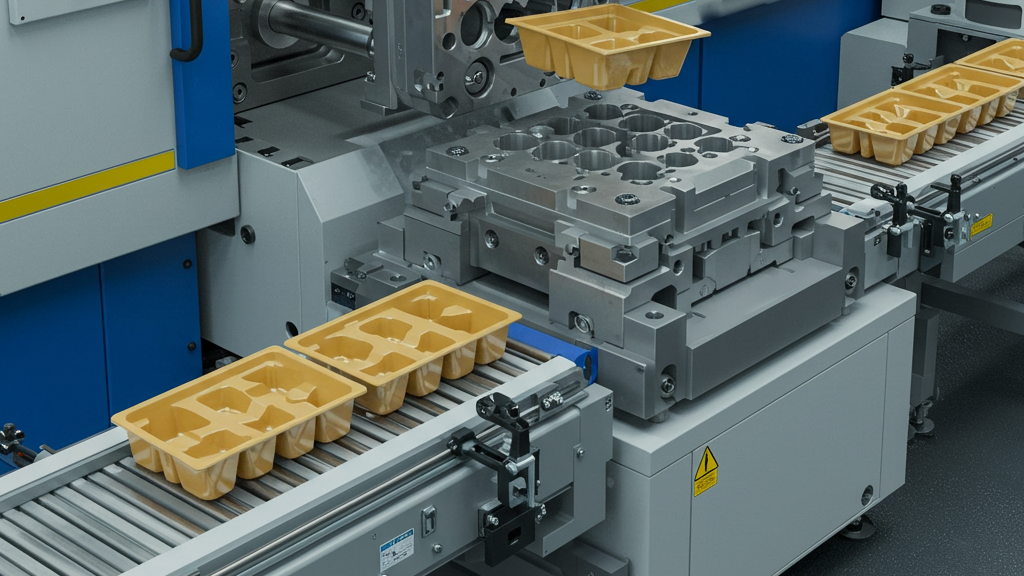

In the rapid mass production of polypropylene packaging, advanced injection molding equipment and precision mold design constitute a solid hardware foundation for efficient production. High-performance injection molding machines can provide stable and precise power and control, while excellent molds directly determine the molding efficiency and quality level of the products.

- Stable and Efficient Molding Capability: Advanced injection molding machines provide precise and rapid injection, ensuring continuous and efficient production.

- Realizing Complex and Precise Designs: Precision molds can form multiple complex packages in one cycle, improving single-cycle efficiency and quality.

- Shortening Production and Mold Change Time: Fast cooling and mold change technologies significantly reduce non-production waiting time, improving equipment utilization.

- Enhancing the Level of Automated Production: Advanced equipment is easy to integrate with automated systems, achieving efficient and low-cost production.

Technology and craft

| Technology/Process Step | Specific Measures | Efficiency Improvement Manifestation |

|---|---|---|

| Material Property Optimization | Selecting PP grades with good flowability; Enhancing PP processability through modification | Shortens filling time, reduces injection pressure, decreases molding defects |

| Hot Runner System Application | Using runnerless or short runner designs; Precisely controlling melt temperature | Eliminates runner scrap processing, shortens injection and holding times, reduces material waste |

| Mold Design Optimization | Employing multi-cavity molds, stack molds; Optimizing cooling systems (conformal cooling); Designing efficient venting systems | Molds more products per cycle, accelerates cooling, reduces molding defects, improves productivity and product quality |

| Precision Injection Parameter Control | Accurately controlling injection speed, pressure, melt temperature, mold temperature, holding time, etc. | Ensures fast and high-quality filling, shortens cycle time, reduces reject rate |

Production Process Management

Efficient production process management and optimization are critical for the rapid mass production of polypropylene injection molded packaging. Combining advanced technologies with scientific management is essential to truly unlock the enormous potential of polypropylene injection molding in the field of rapid mass packaging production.

1.Optimizing Production Planning and Scheduling: Precise scheduling ensures material supply, reduces changeovers, and increases equipment utilization.

2.Shortening Material Flow and Work-in-Process Cycle: Efficient logistics and layout can reduce handling and waiting time, speeding up the production cycle.

3.Strengthening Quality Control and Process Monitoring: Strict quality control and online monitoring can reduce defective products and rework, ensuring stable production.

4.Promoting Lean Production and Continuous Improvement: Lean management can eliminate waste, optimize processes, and improve production efficiency and flexibility.

Conclusion

Polypropylene (PP) is very suitable for injection molding processes due to its excellent fluidity and rapid solidification characteristics, laying the foundation for rapid mass production of packaging. Rational scheduling, smooth logistics, and strict quality control can minimize the waste of time and resources in the production process.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!