The lightweighting trend is driving the widespread use of ABS materials in injection-molded products, especially in automotive and appliance sectors. With reduced wall thickness and simplified structure, the processing window narrows, requiring higher molding precision. This makes defect control a key competitive factor.

By optimizing design and process parameters, manufacturers can not only boost productivity but also avoid rework or scrap. Companies that identify and resolve lightweight ABS molding issues early will gain a cost and efficiency edge.

How to Effectively Identify Bubbles and Sink Marks?

Lightweight ABS often accumulates internal stress during molding, resulting in bubbles and sink marks. These defects are usually hidden inside the part and require CT scanning or ultrasonic testing to detect. Bubble-prone zones are typically associated with uneven wall thickness or inconsistent cooling.

- Insufficient venting: Entrapped air forms bubbles due to poor vent design.

- Injection too fast: Can create air pockets in the mold cavity.

- Uneven cooling: Leads to localized shrink marks and voids.

- Unbalanced wall design: Thicker sections cool slower and cause voids.

How to Optimize and Control Warpage?

Lightweight ABS parts tend to warp more easily after demolding, especially long and thin-walled items. Temperature gradients and cooling asymmetry cause residual stress to release and deform the part. Mold temperature and gate location significantly affect warpage and must be addressed early.

- Low mold temperature: Traps residual stress inside the part.

- Unbalanced flow: Causes uneven shrinkage and bending.

- Poor draft angle: Adds demolding resistance and deformation risk.

- Too thin structures: Lack strength and tend to warp microscopically.

How to Tackle Surface Defects through Process Control?

Surface issues like flow marks, silver streaks, and dull finishes are common in lightweight ABS parts, affecting both aesthetics and fit. These problems stem from improper shear, mold contamination, or thermal imbalances. A stable thermal system and melt management can greatly enhance surface quality.

- Low injection temperature: Leads to flow lines and weld marks.

- Rough mold surface: Magnifies visual defects.

- High resin moisture: Causes bubbles or silver streaks.

- Over-shearing: Creates dull and layered surface textures.

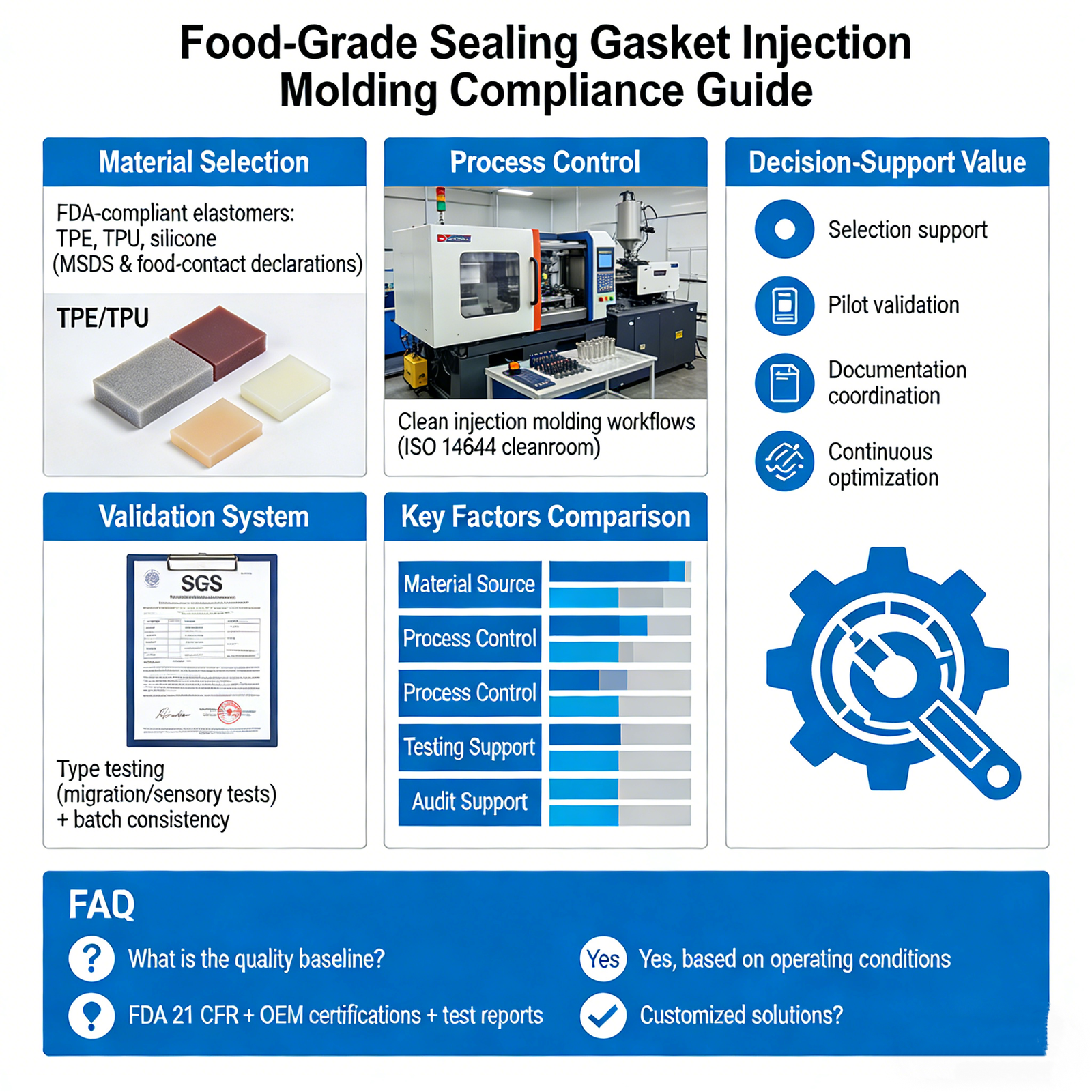

Lightweight ABS Defects vs. Control Strategy

| Defect Type | Root Cause | Detection | Severity | Control Method | Equipment | Cost Impact | Recommended Fix |

|---|---|---|---|---|---|---|---|

| Bubbles | Insufficient venting | Medium | High | Optimize vent design | Medium | High | Improve flow channels |

| Sink Marks | Uneven cooling | High | Medium | Balance wall design | High | Medium | Upgrade cooling system |

| Warpage | Uneven flow/shrink | Low | High | Mold temp/gate tuning | Medium | Medium | Simulation support |

| Surface | Thermal/shear issues | Low | Medium | Melt flow management | Medium | Low | Mold surface polishing |

How to Avoid Defects with Digital Tools?

The push for lightweighting accelerates automation and digitalization in injection molding. Moldflow simulations, process data tracking, and AI-based monitoring enable early defect prediction and proactive optimization. Digital tools are becoming essential for consistent quality and higher yields.

1.Moldflow simulation: Predict defects during flow/cooling/warpage.

2.Data tracking system: Records every molding parameter for traceability.

3.AI visual inspection: Detects and categorizes surface anomalies.

4.Smart mold temp control: Auto-adjusts to maintain thermal balance.

Conclusion

While lightweight ABS molding presents several challenges, high-quality parts can be consistently produced through precise design and advanced processing. Common defects like bubbles, warpage, and surface issues can be addressed early with digital tools and real-time monitoring. Mastering defect identification and resolution is the key to maintaining competitive injection molding operations.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!