Introduction

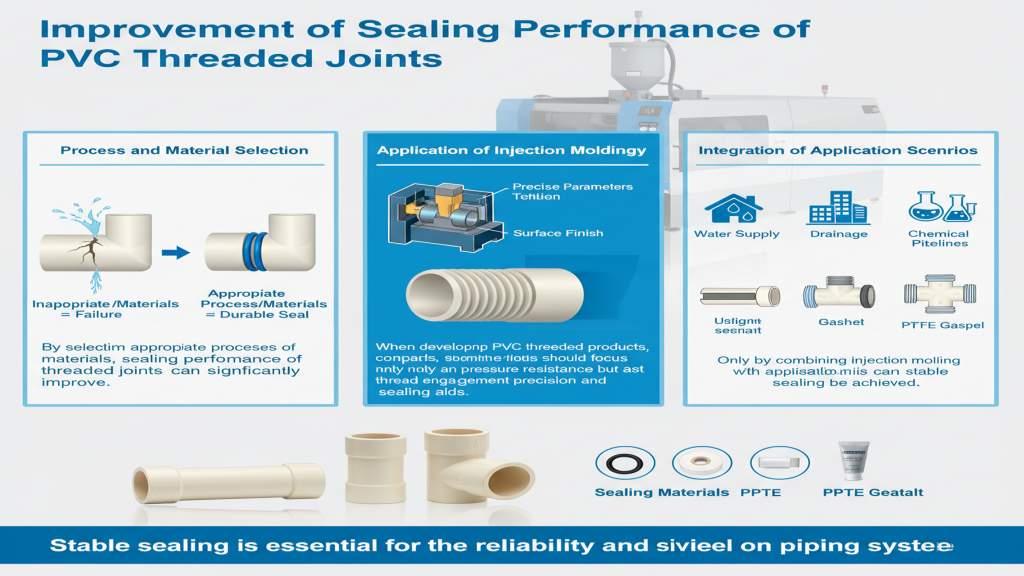

PVC threaded joints are widely used in injection-molded parts, and their sealing performance directly determines the reliability and service life of piping systems. In practice, seal failure often leads to leakage and rework, increasing maintenance costs. By selecting proper processes and materials, the sealing performance of threaded joints can be significantly improved.

When developing PVC threaded products, companies should focus not only on pressure resistance but also on thread engagement precision and sealing aids. Only by combining injection molding technology with application scenarios can stable sealing be achieved.

What process factors affect the sealing of PVC threaded joints?

During injection molding, temperature control, mold design, and molding pressure are key to thread precision and sealing performance. If process parameters are not properly controlled, dimensional deviations and poor fit may occur. Optimizing the process effectively reduces potential sealing risks.

- Mold precision: High-accuracy molds reduce thread gaps

- Injection temperature control: Proper temperature improves molding stability

- Clamping pressure: Ensures complete thread form

- Material flowability: Improves filling and avoids defects

😊 Process optimization is the first step to ensuring PVC thread sealing

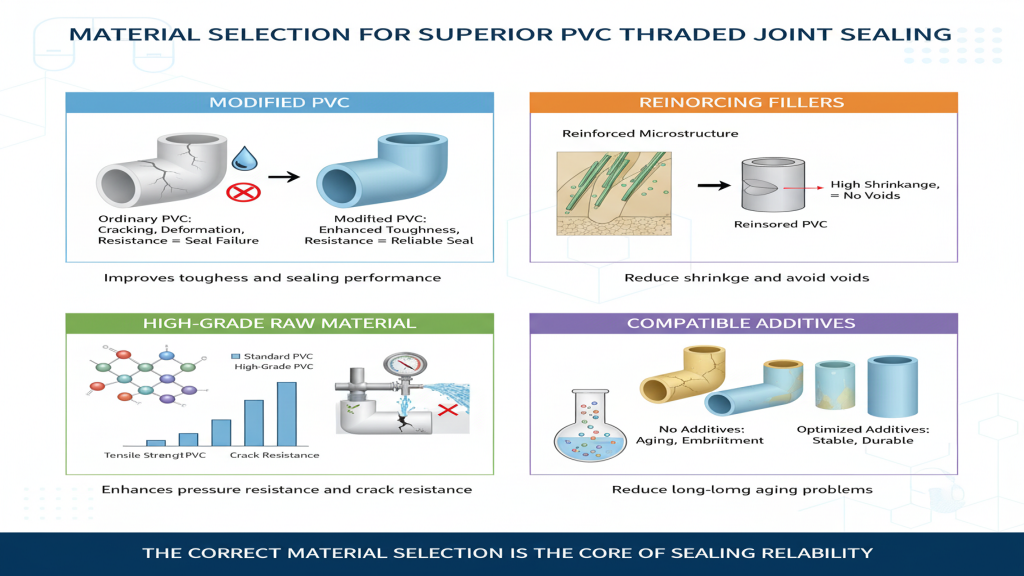

How can material selection improve the sealing of PVC threaded joints?

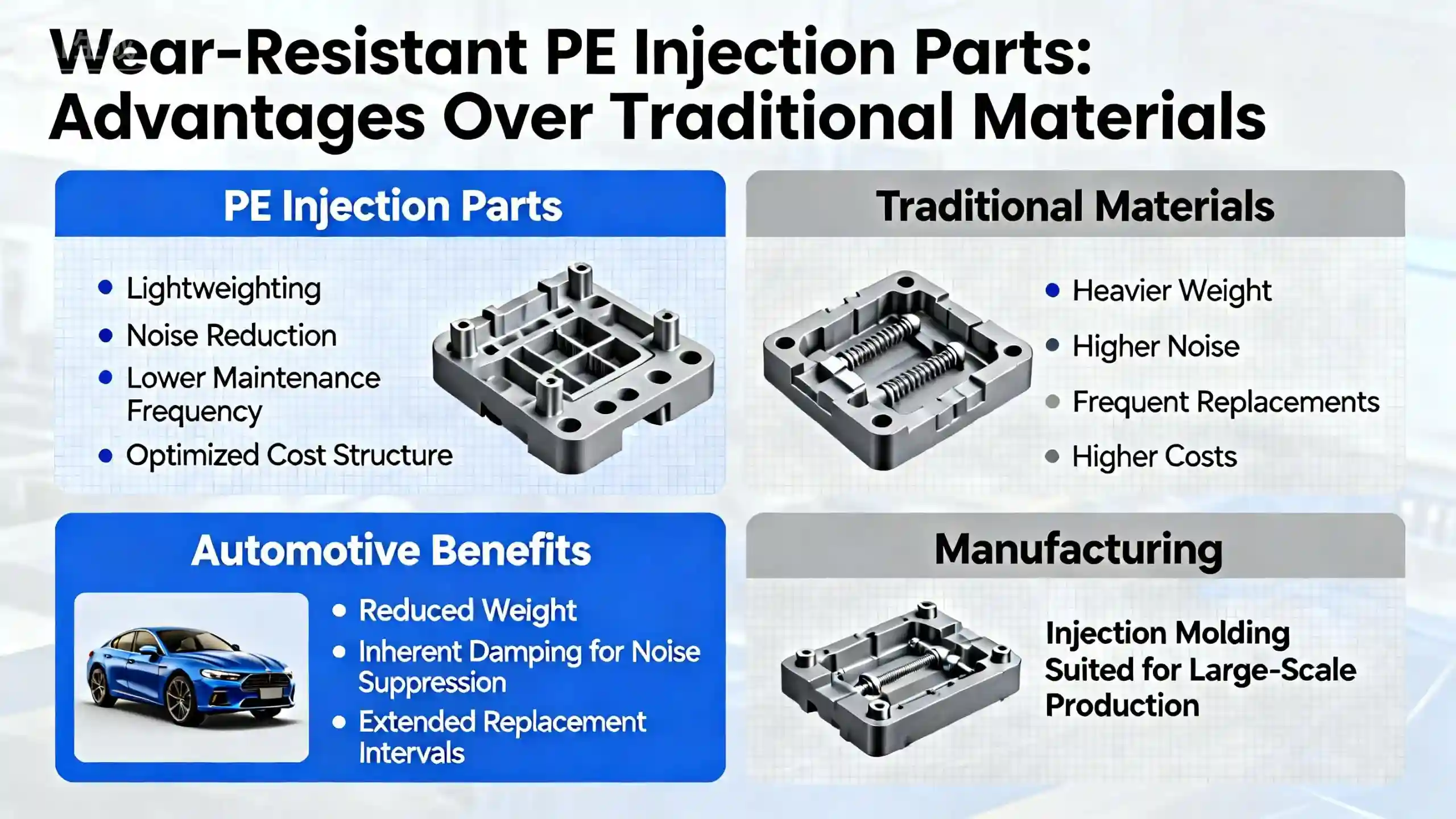

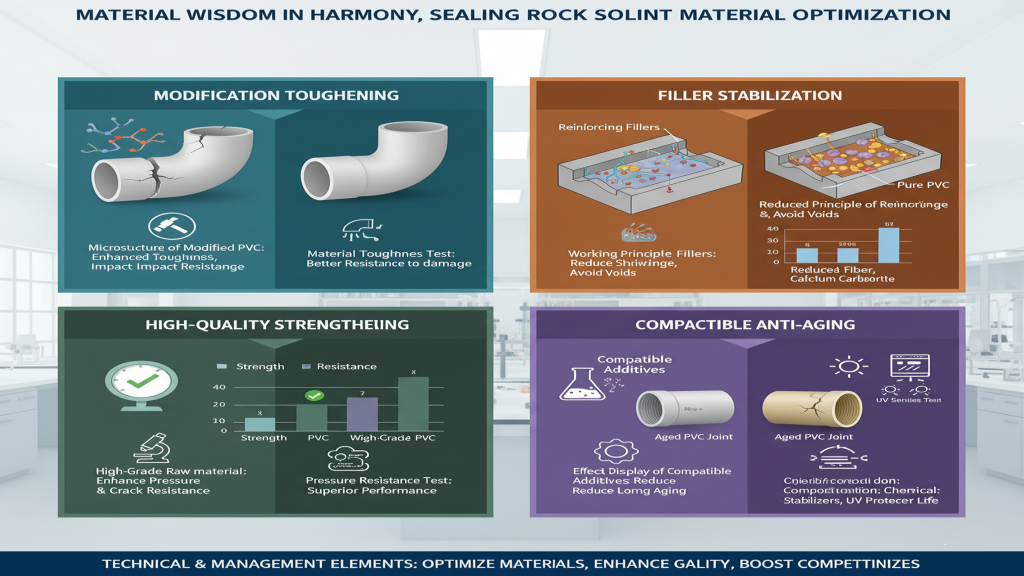

The flowability, shrinkage, and toughness of PVC materials influence the sealing of threads. In specific applications, additives or high-grade PVC can significantly enhance the pressure resistance and sealing of threaded joints.

- Modified PVC: Improves toughness and sealing performance

- Reinforcing fillers: Reduce shrinkage and avoid voids

- High-grade raw material: Enhances pressure resistance and crack resistance

- Compatible additives: Reduce long-term aging problems

🔧 Proper material choice is the core of sealing reliability

What methods ensure stable thread engagement?

Thread engagement stability determines the tightness and durability of the joint. By optimizing thread structure and using sealing tape or sealant, leakage and loosening can be effectively prevented. In injection molding, design and process must complement each other.

- Structural optimization: Scientific thread angle and depth design

- Surface treatment: Increases thread friction

- Sealing aids: Use of sealing tape or sealant

- Assembly precision: Controlled torque ensures stability

🔒 Stable thread engagement is the key safeguard against leakage

PVC Thread Sealing Solutions Comparison

| Solution | Sealing Effect | Cost Control | Ease of Use | Durability |

|---|---|---|---|---|

| High-precision mold | High | Medium | High | High |

| Modified PVC material | High | Medium-High | Medium | High |

| Sealing tape/glue | Medium-High | Low | High | Medium |

| Structural optimization | High | Medium | Medium | High |

For customized PVC threaded solutions, please contact us.

Extended Applications

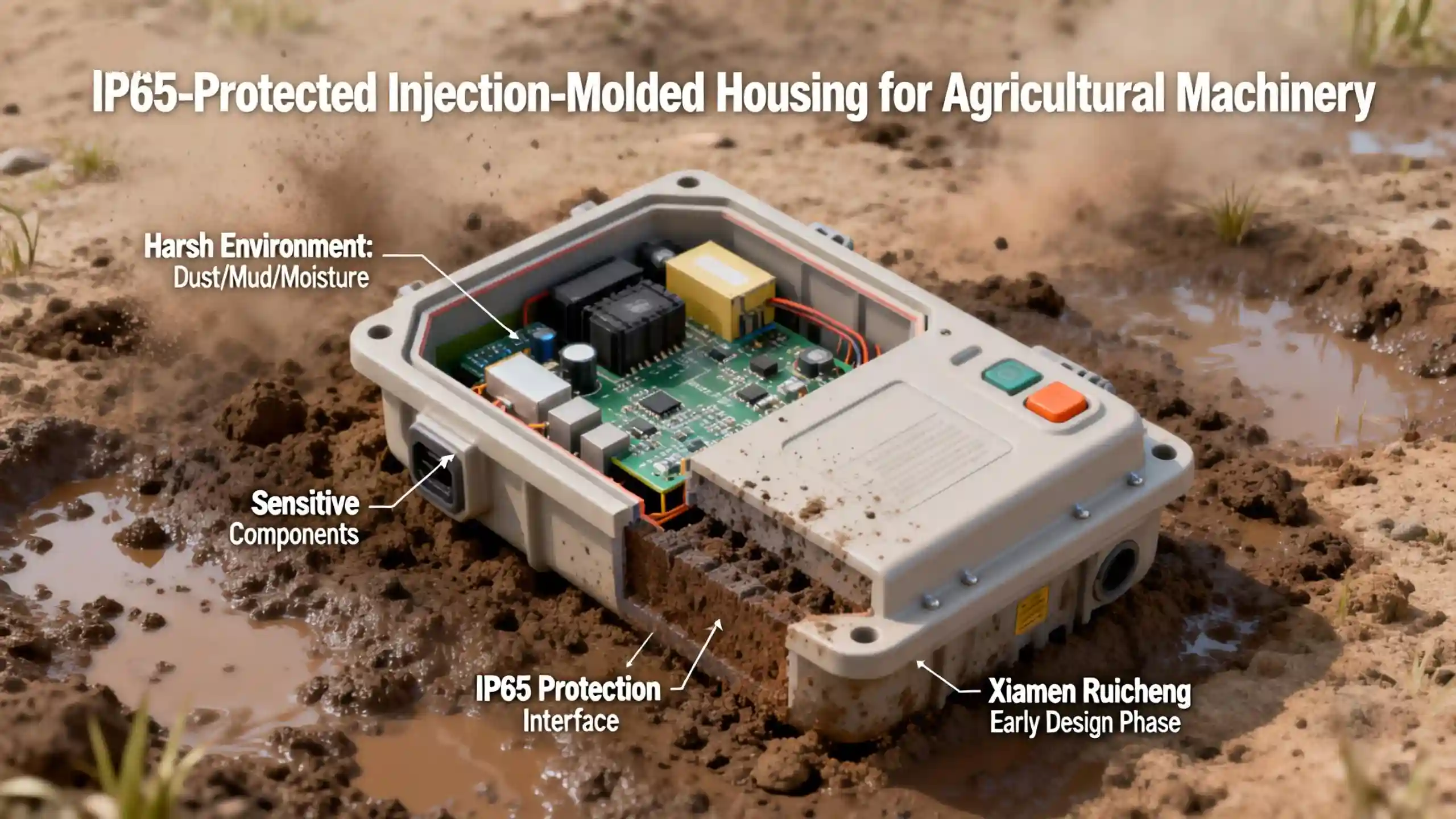

The sealing of PVC threaded joints not only affects household piping but also plays a vital role in industrial fluid systems. In different scenarios, companies need to select sealing strategies according to pressure levels and medium properties. Leveraging injection molding advantages across industries enhances market competitiveness.

1.Household applications: Meets daily water supply needs

2.Industrial transport: Ensures chemical and fluid system safety

3.Agricultural irrigation: Improves connector durability

4.Medical equipment: Provides stable sealed piping interfaces

Conclusion

The sealing of PVC threaded joints depends on a balance of process, material, and structural design. Through scientific control and proper choices, leakage risks can be significantly reduced and service life extended. Companies that adapt solutions to diverse application needs will improve both product competitiveness and customer trust.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!