With digital technology, we can capture key parameters in real time throughout mold design, manufacturing, trials, and mass production. This visibility empowers both clients and production teams to work from a unified source of truth.

Transparent control not only ensures product consistency but also strengthens rapid iteration. When data replaces guesswork, your ABS project moves faster and costs less.

How to Ensure Mold Transparency?

During mold development, digital blueprints, cloud simulation, and real-time monitoring establish an efficient information channel. Clients can monitor mold status and parameters anytime, significantly increasing responsiveness and trust.

- Cloud MES: Consolidates mold dimensions, injection settings, and trial results

- Visual Dashboards: Track molding trials on screens or mobile devices

- Digital Sign-Off: Engineers validate each step online, preventing process gaps

- Customer Portal: Clients join first-article approval and issue tracking

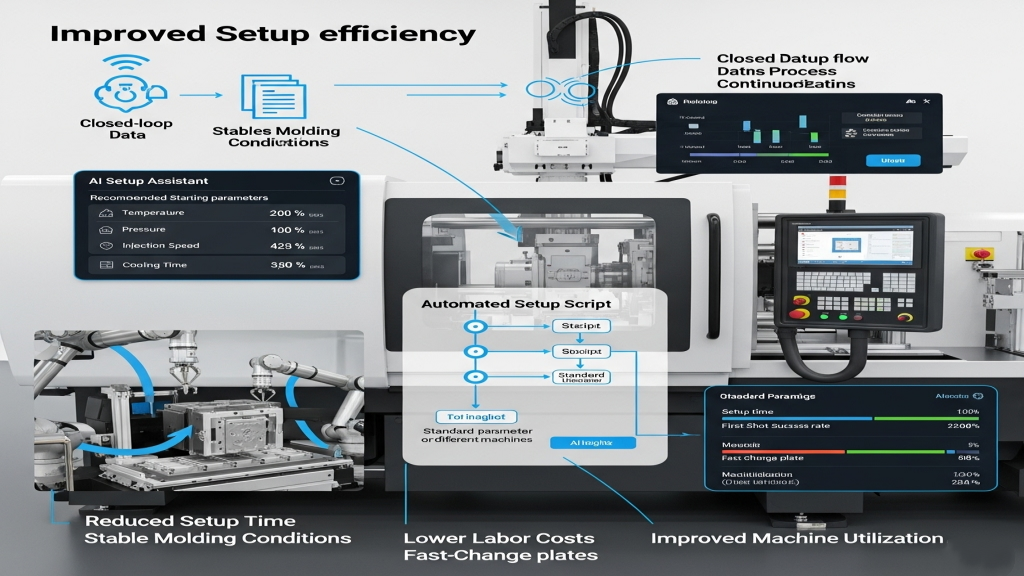

How to Improve Setup Efficiency?

Automated setup scripts and AI optimization algorithms minimize tuning time and stabilize molding conditions. Best process windows are shared across machines, cutting trial-and-error and labor costs.

- AI Setup Assistant: Recommends starting parameters based on past data

- Closed-Loop Data: Each run feeds directly into the process database

- Standard Parameter Library: Shareable across machines, avoiding “knowledge loss”

- Quick Mold Change System: Robotic arms + fast-change plates cut downtime in half

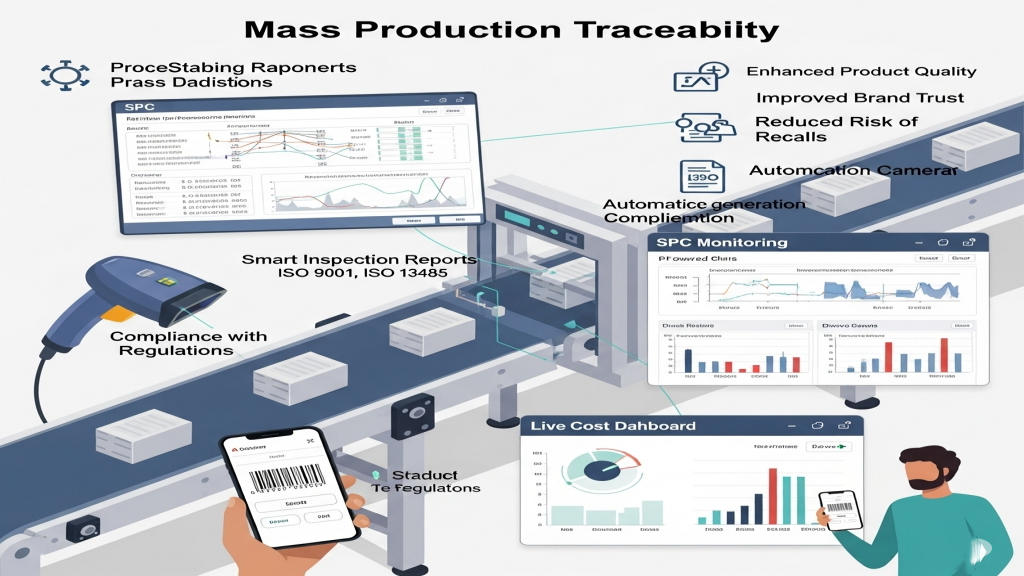

Is Mass Production Traceable?

Barcoding and SPC monitoring ensure traceability and alert for any deviation during production. When customers scan a box and instantly view batch and test records, your brand earns stronger trust.

- Barcode Traceability: Binds batch-product-quality in one link

- Smart Inspection: AI cameras catch visual and dimensional defects in real-time

- Compliance Reports: ISO 9001/13485 evidence archived automatically

- Live Cost Dashboard: Monitors and controls waste in real time

Core Control Solutions Comparison

| Solution | Visibility | Real-Time | Cost | Phase |

|---|---|---|---|---|

| Cloud MES | ★★★★★ | Instant | Medium | Full process |

| AI Setup | ★★★★☆ | Partial | Low | Trial/small batch |

| Barcode Trace | ★★★☆☆ | Partial | Low | Mass production |

| Digital Dashboard | ★★★★☆ | Instant | Low | Full process |

Digital End-to-End Control

Cloud platforms, connected equipment, and data analytics integrate into a digital spine serving design, procurement, production, QA, and customer support. This system not only enhances operations but also upgrades your business model and value chain.

1.Data as Asset: Molding data supports future product design

2.Cloud Collaboration: Real-time cross-departmental access accelerates decisions

3.Predictive Maintenance: Detects equipment issues early, avoids breakdowns

4.Co-Creation with Clients: Supports insight-driven R&D and long-term partnerships

Conclusion

A transparent and controllable ABS production line, anchored in digitalization, transforms traditional experience-based molding into a data-driven system. Breaking information silos fosters agile teamwork and responsive decision-making.With ongoing monitoring, smart optimization, and customer co-involvement, businesses can shorten lead time, reduce costs, and build lasting competitive edges. Success lies in structured planning and consistent execution.

For expert assistance in implementing transparency and control for your ABS production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!