Introduction

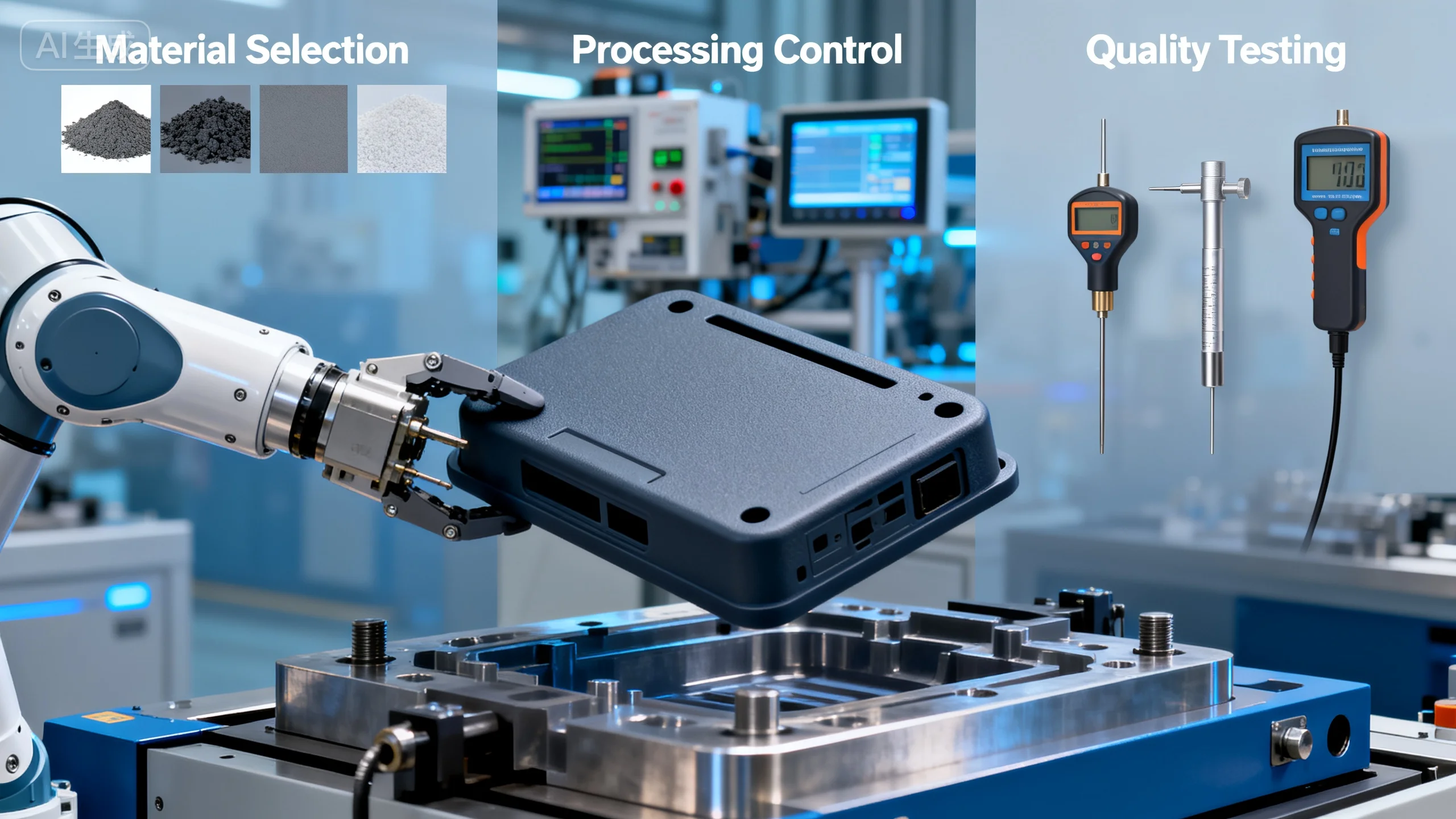

In modern electronics, automotive, and communication devices, stable resistivity defines both performance and safety. Injection-molded components achieve the perfect balance between structure and function through conductive material design and precise molding control. Stable resistivity not only prevents static accumulation but also extends product life.

To achieve consistent conductivity over time, every stage — from material selection and compounding uniformity to mold design — must be managed carefully. A systematic molding process is the foundation of long-term resistivity stability.

What Are the Fundamentals of Conductive Plastic Design?

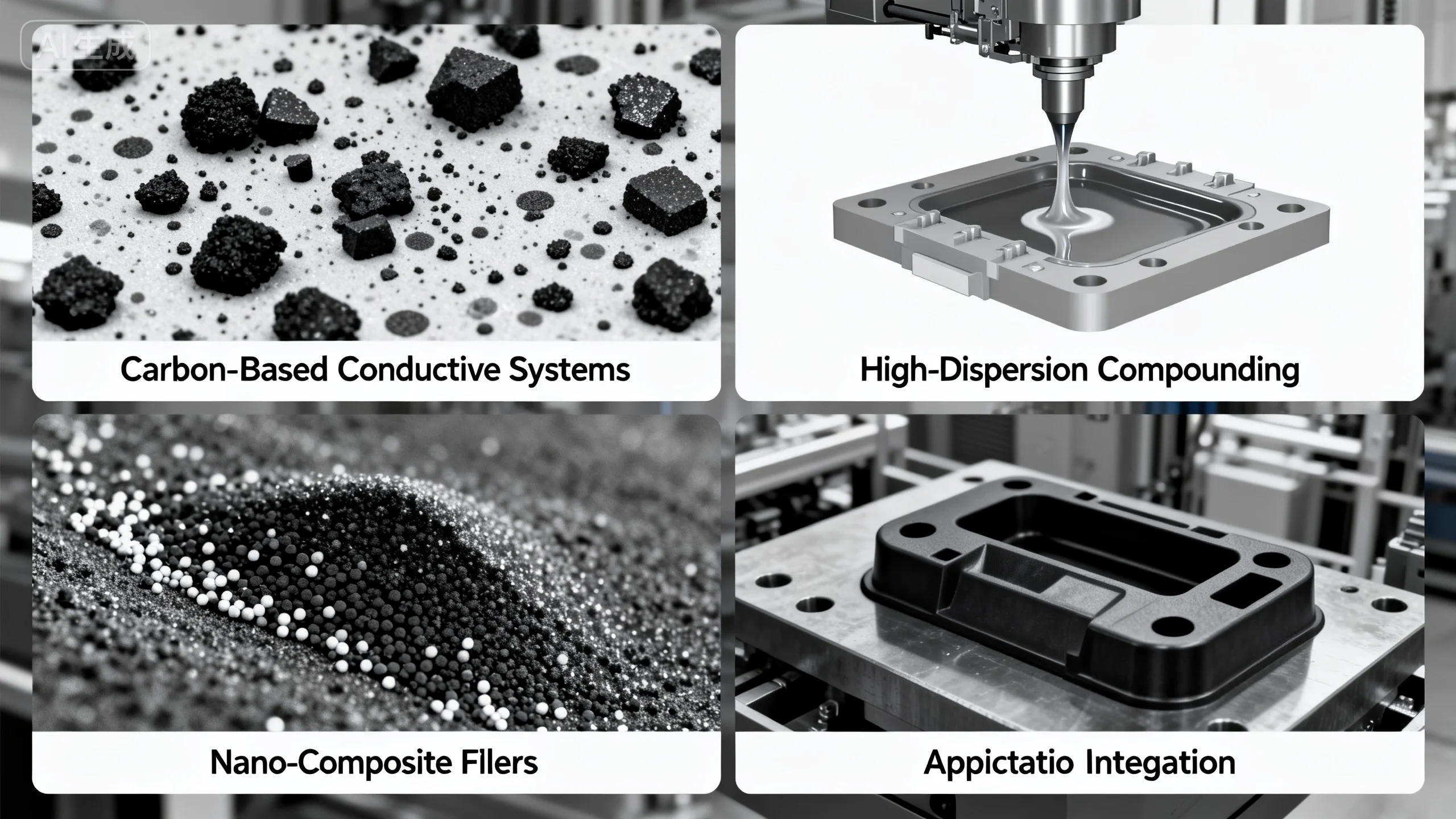

The resistivity of injection-molded parts originates from the conductive plastic formulation. Conductivity is achieved using carbon black, graphite, or carbon nanotube fillers to create charge pathways. The dispersion and concentration of fillers directly determine resistivity stability and repeatability. Precise control of microstructure during formulation is the first step toward achieving reliable electrical performance.

- Carbon-Based Conductive Systems: Use carbon black or graphite for general anti-static applications.

- High-Dispersion Compounding: Optimize melt flow to prevent filler agglomeration and uneven resistivity.

- Nano-Composite Fillers: Utilize CNT or graphene for more uniform conductive networks.

- Material Purity Control: Avoid impurities that cause dielectric loss or micro-discharges.

⚡ Material purity and filler dispersion are the starting points of stable resistivity.

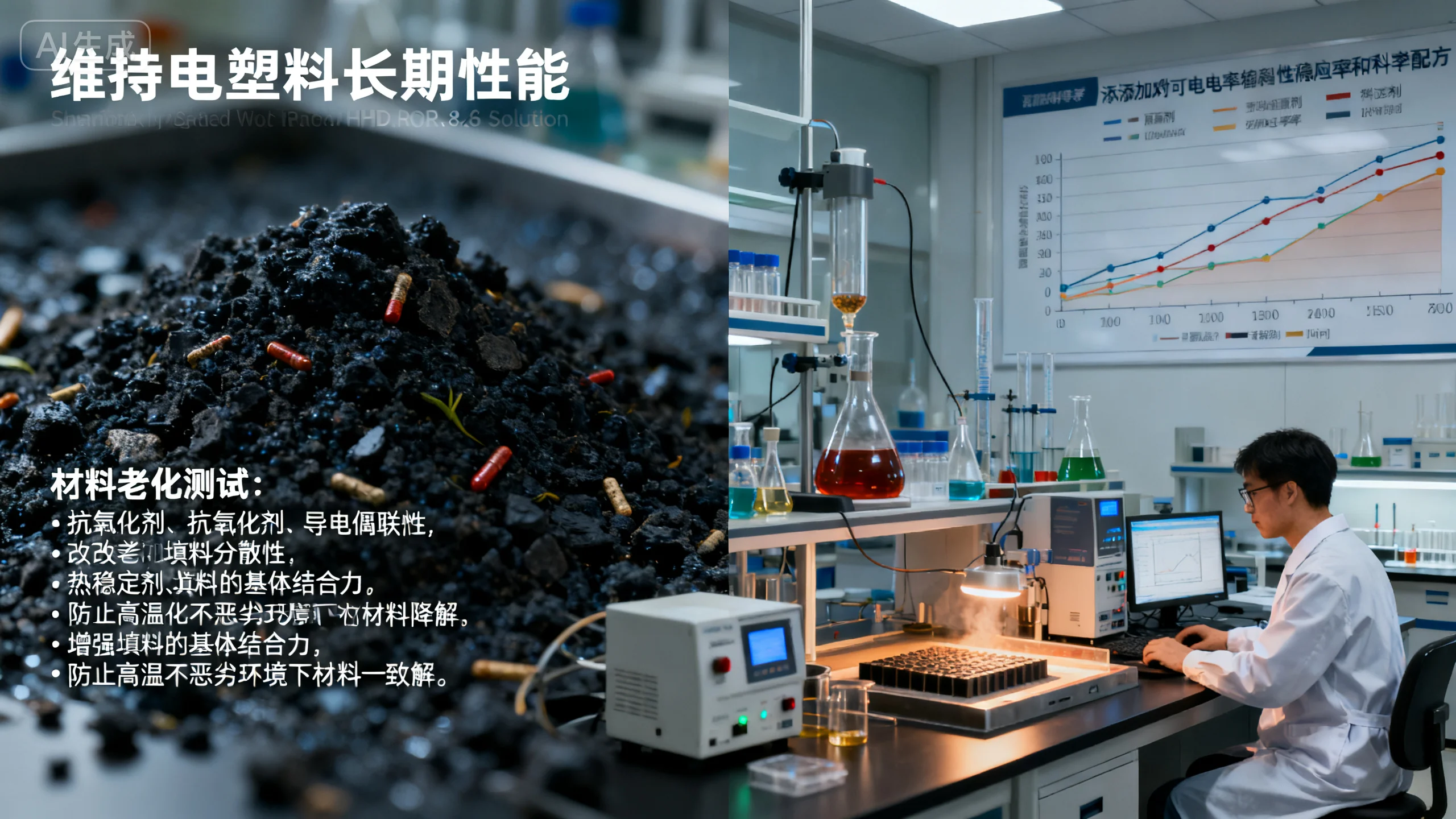

How Do Additives Affect Long-Term Resistivity Stability?

In conductive plastics, additives not only influence processability but can also alter electrical behavior. Certain lubricants or flame retardants may create insulating layers that interrupt conductive pathways. Balanced additive design is critical to maintaining long-term electrical stability.

- Antioxidant Systems: Delay filler oxidation and preserve resistivity uniformity.

- Conductive Coupling Agents: Improve bonding between fillers and resin to prevent migration.

- Thermal Stabilizers: Prevent degradation during molding that could disrupt conductivity.

- Surface Activators: Enhance filler-to-matrix contact to strengthen conduction pathways.

🔋 Scientific formulation ensures that conductivity remains consistent over time.

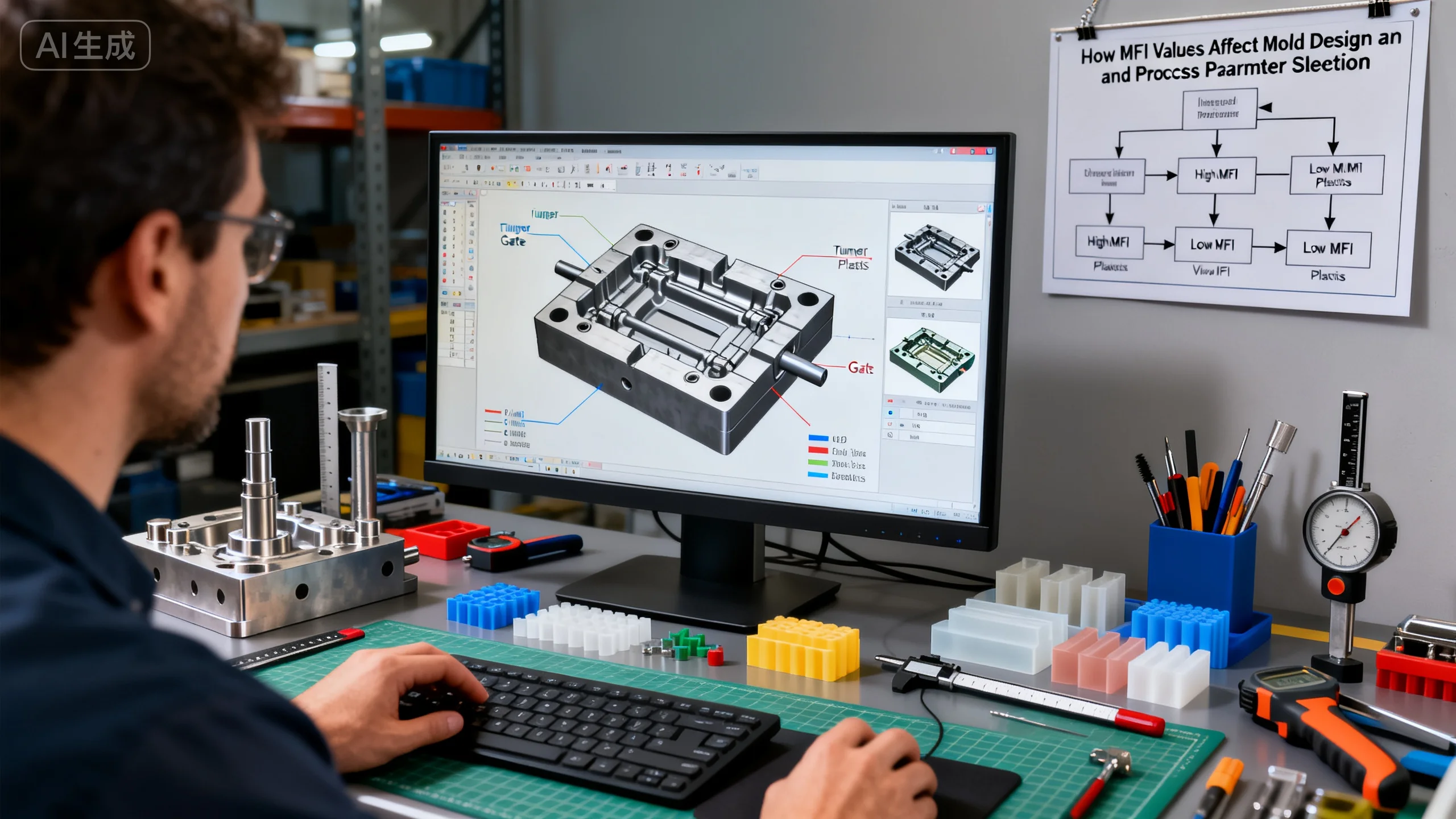

How Does the Molding Process Influence Conductive Networks?

Processing parameters such as temperature, pressure, and cooling speed directly impact filler orientation. If the conductive network is disrupted by shear or uneven flow, resistivity uniformity will decline. Precise process control is the key to consistent electrical performance.

- Temperature Control: Prevent filler segregation or incomplete melting.

- Cavity Pressure Optimization: Maintain continuous filler distribution across the part.

- Cooling Rate Management: Reduce internal stress and preserve network integrity.

- Automated Feedback Systems: Adjust process parameters in real-time using resistance monitoring.

⚙️ Accurate process control keeps the conductive network intact and reliable.

Comparison of Resistivity Control Solutions

| Solution Type | Conductive Medium | Process Complexity | Cost Efficiency | Stability | Application |

|---|---|---|---|---|---|

| Carbon Black | Carbon Black | Low | Excellent | Moderate | General Anti-Static Parts |

| Graphite | Graphite Powder | Medium | Good | Good | Electrical Housings |

| CNT | Carbon Nanotubes | High | Moderate | Excellent | Precision Electronics |

| Hybrid System | CNT + Graphene | High | Moderate | Superior | High-End Automotive Components |

Innovative conductive formulations help manufacturers balance conductivity and mechanical strength — explore the right solution for your needs by contacting us.

Extended Strategies for Resistivity Optimization

Achieving stable resistivity requires more than proper materials and processes — it also depends on robust monitoring and traceability systems. A closed-loop quality control framework ensures long-term conductive performance and product reliability. This is how manufacturers evolve from “qualified parts” to “trusted performance.”

1.Real-Time Resistance Monitoring: Continuously record resistivity data during production.

2.Batch Formulation Traceability: Ensure filler consistency across production lots.

3.Humidity Regulation: Prevent moisture absorption that affects electrical stability.

4.Full-Process Digital Analysis: Apply AI to predict and optimize conductivity performance.

Conclusion

Ensuring stable resistivity in injection-molded parts requires a comprehensive approach — from material design and additive control to precise process tuning. Consistent electrical properties not only showcase technical capability but also define product reliability and competitiveness. As data-driven manufacturing evolves, resistivity control will become more predictive and traceable than ever.

For expert assistance in implementing conductive stability for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!