Polycarbonate is widely used due to its excellent performance, but its lack of antibacterial properties poses a challenge in fields with high hygiene and safety requirements. The adhesion and reproduction of microorganisms not only brings the risk of infection but also affects the material performance. Therefore, imparting antibacterial properties to polycarbonate is crucial, which can significantly expand its application scope. This article will explore various strategies for imparting antibacterial properties to polycarbonate and analyze their principles and prospects.

To impart antibacterial properties to polycarbonate, there are mainly two strategies. One is to add antibacterial agents to the polycarbonate matrix, achieving antibacterial effects by releasing active substances. The other is to modify the polycarbonate surface to construct a contact-killing antibacterial structure or introduce antibacterial groups. Next, we will introduce and analyze these two main antibacterial methods in detail.

What are the methods for making PC antibacterial?

Imparting antibacterial properties to polycarbonate (PC) is crucial for enhancing its applications in hygiene-sensitive areas. Currently, researchers have developed various strategies to inhibit the growth and reproduction of microorganisms on polycarbonate surfaces.

- Blend Modification with Antibacterial Agents: By adding antibacterial agents into the polycarbonate, these agents exert antibacterial effects either within the material or on its surface.

- Surface Coating Technology: Covering the polycarbonate surface with a coating containing antibacterial substances to inhibit microbial growth.

- Surface Grafting Modification: Directly fixing antibacterial groups or molecules onto the polycarbonate surface to form an antibacterial layer.

- Physical Surface Structure Construction: Utilizing micro/nano structures to alter the surface morphology of polycarbonate in order to inhibit bacterial adhesion.

How do antibacterial methods work?

Understanding the mechanisms of action of different antibacterial methods is crucial for optimizing the antibacterial properties of polycarbonate. These methods interfere with the growth, reproduction, or adhesion processes of microorganisms through various pathways, thereby achieving antibacterial effects.

- Blend Modification with Antibacterial Agents: By releasing toxic antibacterial components, they interfere with the key physiological processes of microorganisms.

- Surface Coating Technology: Utilizing the antibacterial substances in the coating to directly contact and disrupt or inhibit the growth of microorganisms.

- Surface Grafting Modification: Through the interaction of surface-fixed antibacterial groups with microorganisms, their structure or function is disrupted.

- Physical Surface Structure Construction: Utilizing special micro/nano morphologies to physically damage bacteria or reduce their adhesion.

How to Choose an Antimicrobial Method?

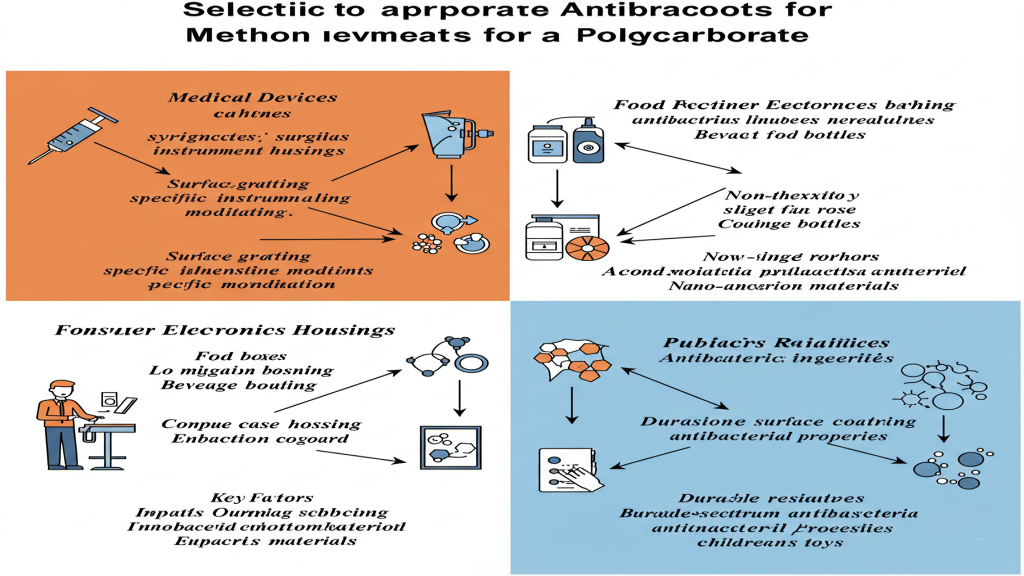

Selecting the appropriate polycarbonate antimicrobial strategy is crucial for different application needs. Factors such as the material's usage environment, requirements for antimicrobial performance, and cost considerations will all influence the final method selection.

- Medical Device Field: Durable and safe antimicrobial properties are key. Surface grafting or specific blending modification are more suitable.

- Food Packaging Field: Ensuring non-toxicity and no impact on food quality is necessary. Antimicrobial methods with low migration should be selected.

- Consumer Electronic Product Housings: Balancing cost and impact on original performance, blending or surface coatings can be considered.

- Public Facilities and Daily Necessities: Abrasion resistance and broad-spectrum antimicrobial properties are important. Surface coatings or grafting modification can be considered.

Technical path and characteristics

| Technology Path | Antibacterial Principle | Advantages | Disadvantages | Potential Application Scenarios |

|---|---|---|---|---|

| Blend Modification with Antimicrobial Agents | Antimicrobial agents release antibacterial components, interfering with microbial growth or reproduction. | Relatively simple operation, potentially lower cost, can impart bulk antibacterial properties to the material. | Antimicrobial agents may migrate and leach out, limited durability, may affect the original properties of the material, potential safety risks with some agents. | Mass consumer goods, scenarios with moderate antibacterial requirements and less emphasis on durability. |

| Surface Coating Technology | Antibacterial substances in the coating directly contact and kill or inhibit microorganisms. | Wide selection of antibacterial substances, relatively flexible operation, minimal impact on the substrate's original properties. | Coating may wear or detach, limited durability, uniformity may be an issue. | Non-implantable medical devices, food packaging, electronic product housings, public facility surfaces. |

| Surface Grafting Modification | Antimicrobial groups or molecules fixed on the surface interact with microorganisms, disrupting their structure or function. | Durable antibacterial properties, less prone to detachment, minimal impact on substrate properties, relatively high safety. | Relatively complex operation, potentially higher cost, limited surface modification depth. | Implantable medical devices, long-term human contact devices, scenarios with high demands for antibacterial durability. |

| Physical Surface Structure Construction | Special micro/nanostructures physically damage bacterial cells or reduce bacterial adhesion. | No need to add antibacterial agents, high safety, potentially long-lasting. | Higher technical difficulty, potentially higher cost, may affect the optical and mechanical properties of the material, limited applicability. | Specific medical device surfaces, biosensors, special applications requiring avoidance of chemical antibacterial agents. |

Future of PC Antimicrobial Technology

Future research will no longer be solely focused on providing materials with basic antimicrobial capabilities, but will evolve towards more intelligent, environmentally friendly, and functional directions. Exploring these emerging trends will help us better understand and predict the future application prospects of antimicrobial polycarbonate.

1.Multifunctional Integration: Future antimicrobial polycarbonates will integrate multiple functions to address complex needs.

2.Enhanced Environmental Friendliness and Biocompatibility: Developing safer, more environmentally friendly antimicrobial strategies and improving biocompatibility are important trends.

3.Long-lasting and Smart Antimicrobial Properties: Achieving more durable antimicrobial effects and endowing materials with intelligent responsiveness are research priorities.

4.Customized and Precise Applications: Developing polycarbonate materials with customized antimicrobial properties for specific needs.

Conclusion

Imparting antimicrobial properties to polycarbonate is key to expanding its applications. Existing methods include adding antimicrobial agents, surface coatings, surface grafting, and constructing physical structures. These methods each have advantages and disadvantages and are suitable for different scenarios. These advancements will lead to wider applications in fields such as healthcare, food, and electronics.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!