Introduction

Injection speed is a decisive factor influencing polymer molecular orientation, directly shaping the melt flow and shear rate. When the speed is too high, molecular chains tend to over-align along the flow direction, causing anisotropic mechanical behavior. Conversely, too low a speed leads to incomplete filling, weld lines, and internal stress.

In industrial molding, the right injection speed achieves molecular-level flow regulation, enhancing transparency, mechanical strength, and dimensional stability. Mastering the dynamics of speed control is the key to achieving balanced performance in advanced injection-molded parts.

How Does Injection Speed Affect Molecular Orientation?

The melt flow velocity during injection determines the alignment pattern of polymer chains. High-speed injection improves filling but may overstretch molecular chains. Balancing injection speed helps achieve uniform molecular orientation and minimize internal stress in molded parts.

- Optimize Shear Rate: Adjust shear to control molecular stretch.

- Precise Holding Pressure Switch: Transition to holding pressure at the right moment for flow stability.

- Reduce Local Flow Resistance: Minimize velocity gradients through flow channel optimization.

- Dynamic Process Monitoring: Real-time feedback to maintain orientation consistency.

😊 Controlling injection speed is the key to achieving ordered molecular orientation and stable product performance.

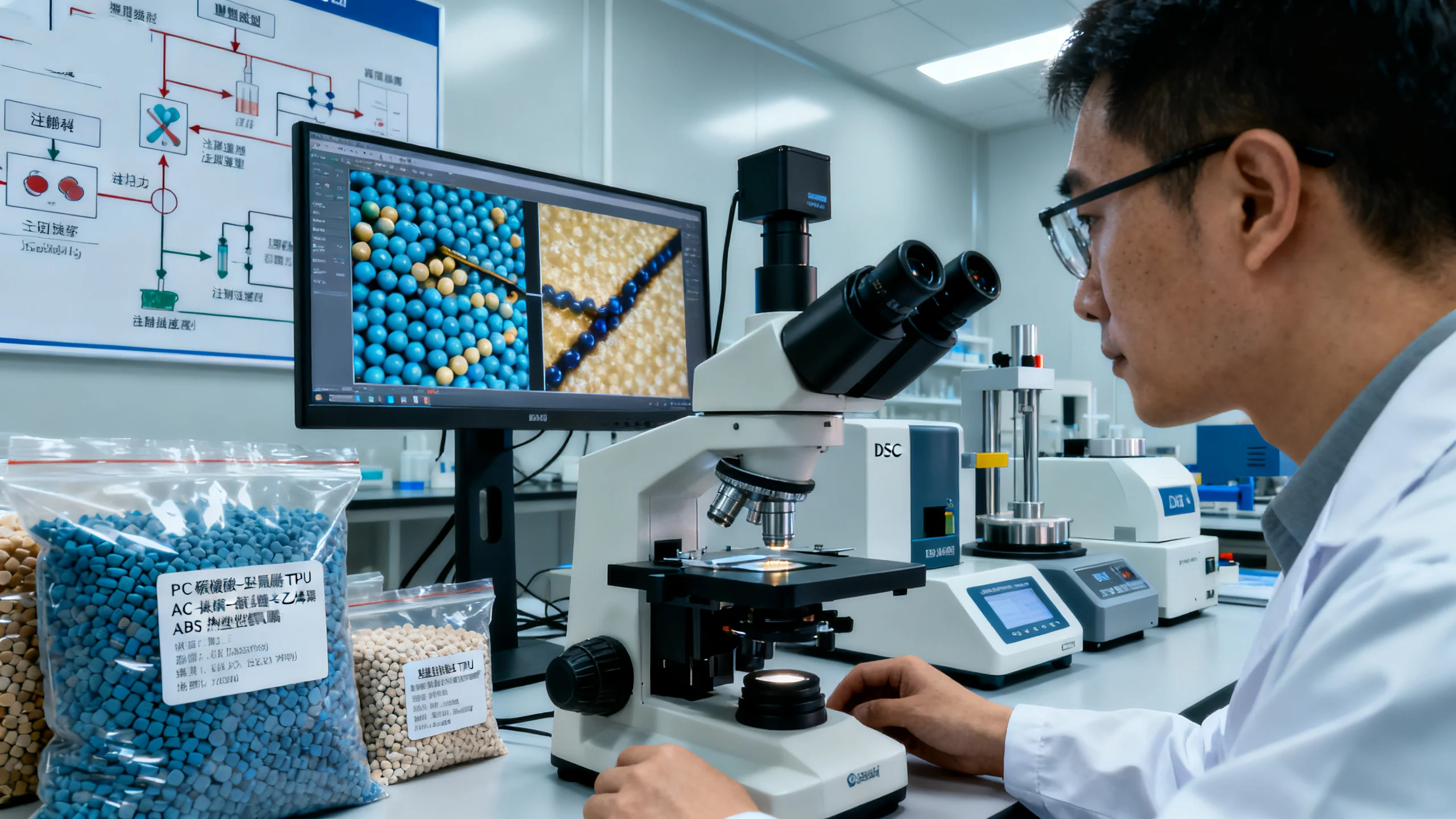

How to Evaluate Orientation Effects at Different Injection Speeds?

Orientation can be quantified through birefringence, stress analysis, and surface inspection. The molecular alignment difference under various speeds directly impacts transparency and toughness. Accurate evaluation helps establish the relationship between speed and performance.

- Polarized Microscopy: Visualize optical interference from orientation.

- Thermo-Mechanical Testing: Measure stress variations caused by alignment.

- Flow Simulation Support: Predict orientation trends with CAE modeling.

- Cross-Sectional Observation: Inspect uniformity of molecular arrangement.

🔍 Scientific evaluation builds the data foundation for optimizing injection speed.

How to Improve Orientation Through Temperature-Speed Coordination?

Temperature and injection speed jointly determine molecular mobility and orientation rate. When temperature or speed is mismatched, molecules freeze prematurely, reducing dimensional stability. Coordinated control ensures optimal flow and molecular alignment.

- Mold Temperature Management: Balance temperature to enhance molecular movement.

- Optimize Melt Temperature: Increase flexibility and prevent over-orientation.

- Multi-Stage Injection: Use velocity gradients to create layered flow.

- Controlled Cooling Rate: Fix orientation during steady cooling.

🔥 Temperature-speed synergy is the dual force behind orientation uniformity and stability.

Injection Speed vs. Molecular Orientation

| Parameter | Low Speed | Medium Speed | High Speed | Multi-Stage Speed |

|---|---|---|---|---|

| Orientation Degree | Low | Moderate | High | Controllable |

| Residual Stress | Low | Controlled | High | Minimal |

| Surface Quality | Flow Marks | Smooth | Stretch Marks | Excellent |

| Optical Clarity | Average | Clear | Anisotropic | Stable |

Want to achieve both orientation control and superior molding quality? contact us today for a customized injection speed optimization solution!

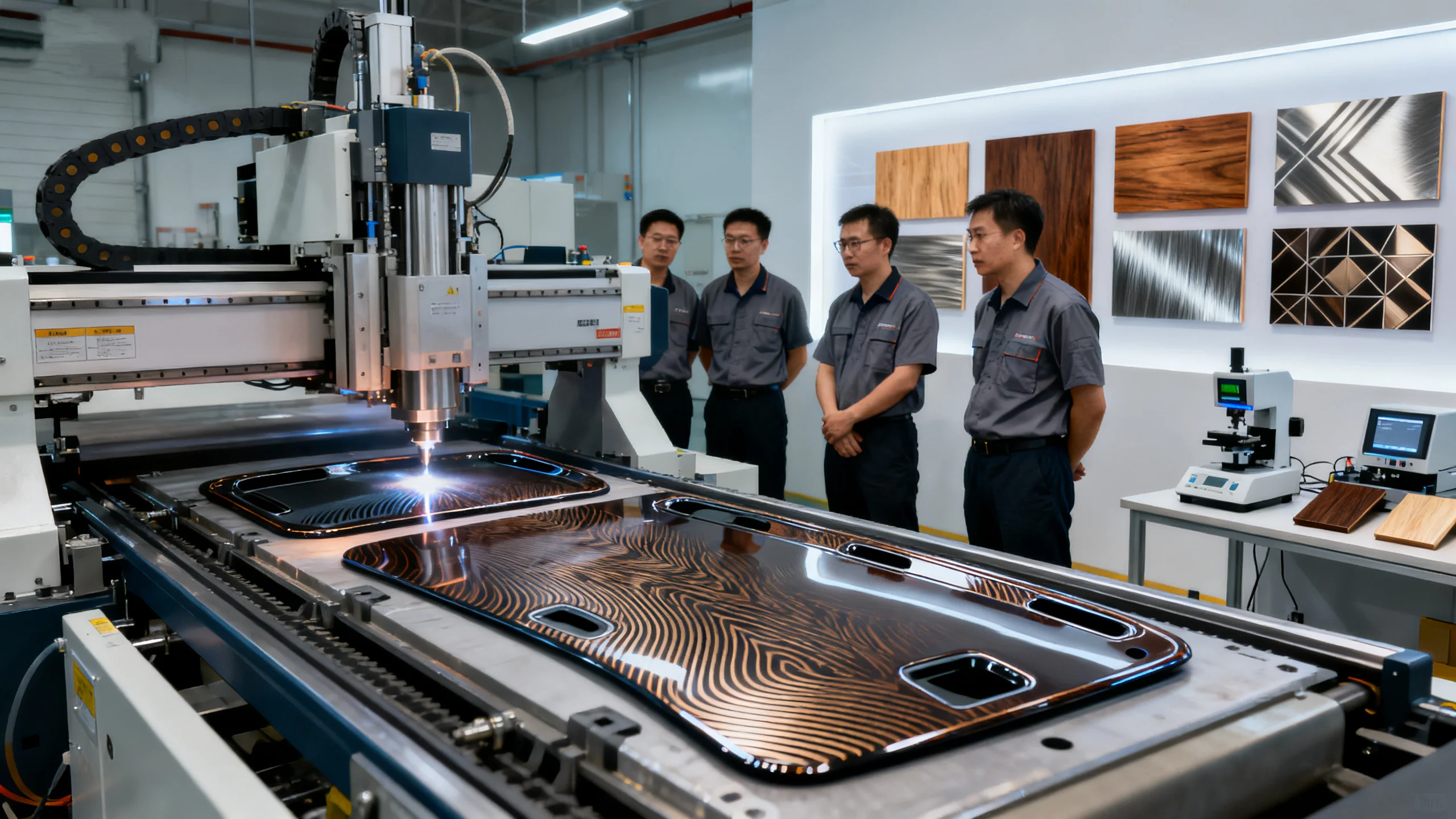

Precision Control for Quality Upgrade

Injection speed not only affects molecular orientation but also dictates overall stress distribution and visual appearance. Through precise multi-stage speed control, issues like flow marks, warpage, and optical distortion can be eliminated. Modern molding systems integrate speed, pressure, and temperature under intelligent control for unmatched stability.

1.Segmented Speed Programming: Achieves layered molecular flow control.

2.Closed-Loop Feedback System: Automatically corrects deviations in real time.

3.Smart Process Database: Builds models for speed-orientation optimization.

4.Production Stability Validation: Ensures continuous process consistency.

Conclusion

Controlling molecular orientation through injection speed is vital for enhancing product performance and appearance. It combines fluid dynamics with molecular engineering to optimize both function and aesthetics. Proper speed regulation is not just a process adjustment — it’s a strategic advantage in modern molding.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!