Polycarbonate is widely used in safety and industrial fields for its excellent impact resistance, while acrylic is favored in lighting and optical applications for its high transparency. In injection molding, balancing these two material advantages is a key technical challenge.

In high-performance applications, customers demand both durability and optical clarity. The balance between material selection and process control determines the final product’s performance.

How to Enhance the Composite Performance of PC and PMMA?

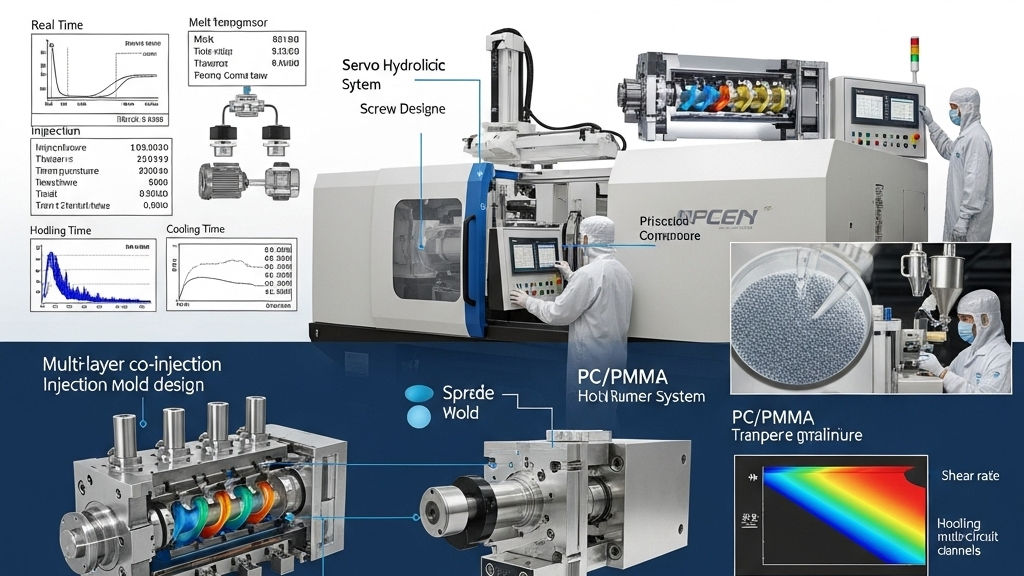

In practice, PC and acrylic usually cannot be directly combined and require blending technologies or intermediate layers. Optimizing injection molding temperature and shear rate improves interface adhesion and reduces cracking risk.

- Blend Optimization: Adding compatibilizers to improve material fusion.

- Mold Temperature Strategy: Directly impacts light transmittance and crystalline structure.

- Structural Design: Multi-layer or hollow designs reduce stress concentrations.

- Surface Coating: Enhances transparency and minimizes interface defects.

How to Address the Physical Conflicts Between Them?

PC is tough and flexible but has lower refractive index; acrylic is highly transparent but brittle. Material modification and process tuning can effectively resolve these contradictions.

- Copolymerization: Introduce flexible chains to improve acrylic’s impact resistance.

- Microstructure Adjustment: Nano-layered arrangements to balance performance.

- Shear Rate Control: Reduces internal stress during injection.

- Interface Buffering: Transitional layers ease material mismatch.

How to Maintain Optical Quality?

In mixed applications, acrylic can degrade thermally, while PC is prone to internal stress causing refraction issues. Controlling injection parameters and mold design is key to preserving optical properties.

- Low-Temp Injection: Reduces optical defects.

- Mold Surface Precision: Mirror-polished surfaces preserve clarity.

- Material Purity: Fewer impurities reduce yellowing and scattering.

- Stress Relief Processing: Annealing reduces post-molding optical deformation.

Performance Comparison of PC/PMMA in Different Applications

| Performance | Polycarbonate (PC) | Acrylic (PMMA) | PC+PMMA Blend | Structural Composite |

|---|---|---|---|---|

| Impact Resistance | Very High | Moderate | High | Excellent |

| Optical Clarity | Medium | Very High | High | High |

| Thermal Stability | Good | Moderate | Good | Excellent |

| Molding Complexity | High | Medium | High | Medium |

| Cost Control | Moderate-High | Low | Moderate | Moderate-High |

| Market Flexibility | High | Medium | High | High |

Market-Oriented Composite Development

The development of composites offers injection molders more competitive products and opens new business collaborations. Many industries now consider PC-Acrylic hybrids as premium solutions.

1.Optical Housing Materials: Widely used in premium lighting applications.

2.Safety & Display Integration: Transparent shields and anti-impact panels.

3.Medical Transparent Devices: Stability and clarity meet medical-grade needs.

4.Automotive Interior Integration: Partially optical and impact-resistant in one.

Conclusion

PC-PMMA hybrid solutions offer dual benefits in applications demanding impact resistance and high light transmittance. Process control, structural design, and material engineering are the key factors to balance both. With continued optimization, such composites will see expanded adoption in advanced scenarios like lighting, safety, and healthcare.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!