Introduction

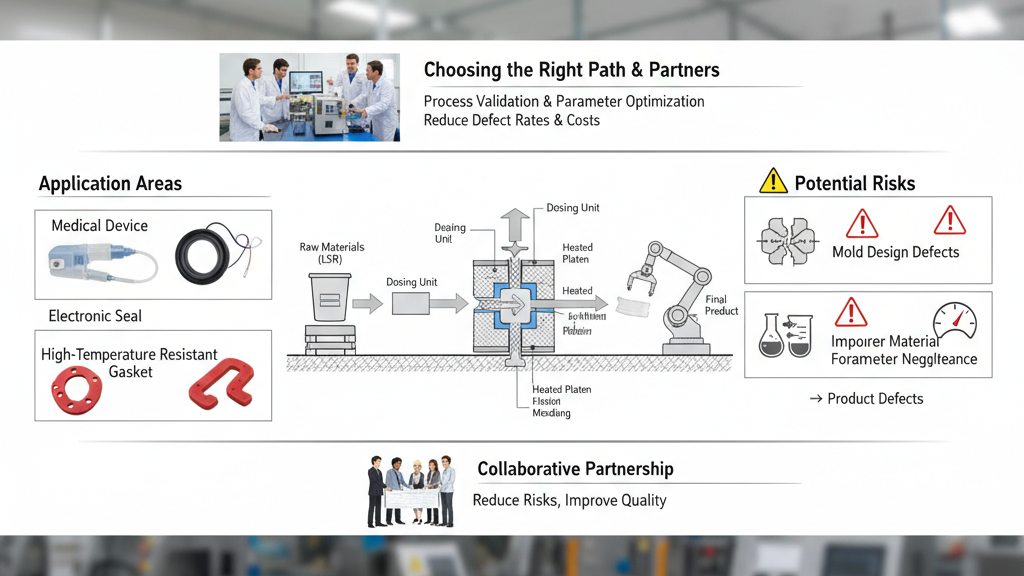

Silicone injection molding is widely applied in medical devices, electronic seals, and high-temperature resistant parts, but hidden risks exist throughout the process. Choosing the right process path is the key to avoiding traps. Conducting process validation before mass production helps reduce defective rates.

Negligence in mold design, material formulation, or molding parameters can easily lead to product defects. By working with experienced teams, companies can lower both costs and risks. Therefore, selecting the right partner becomes critical.

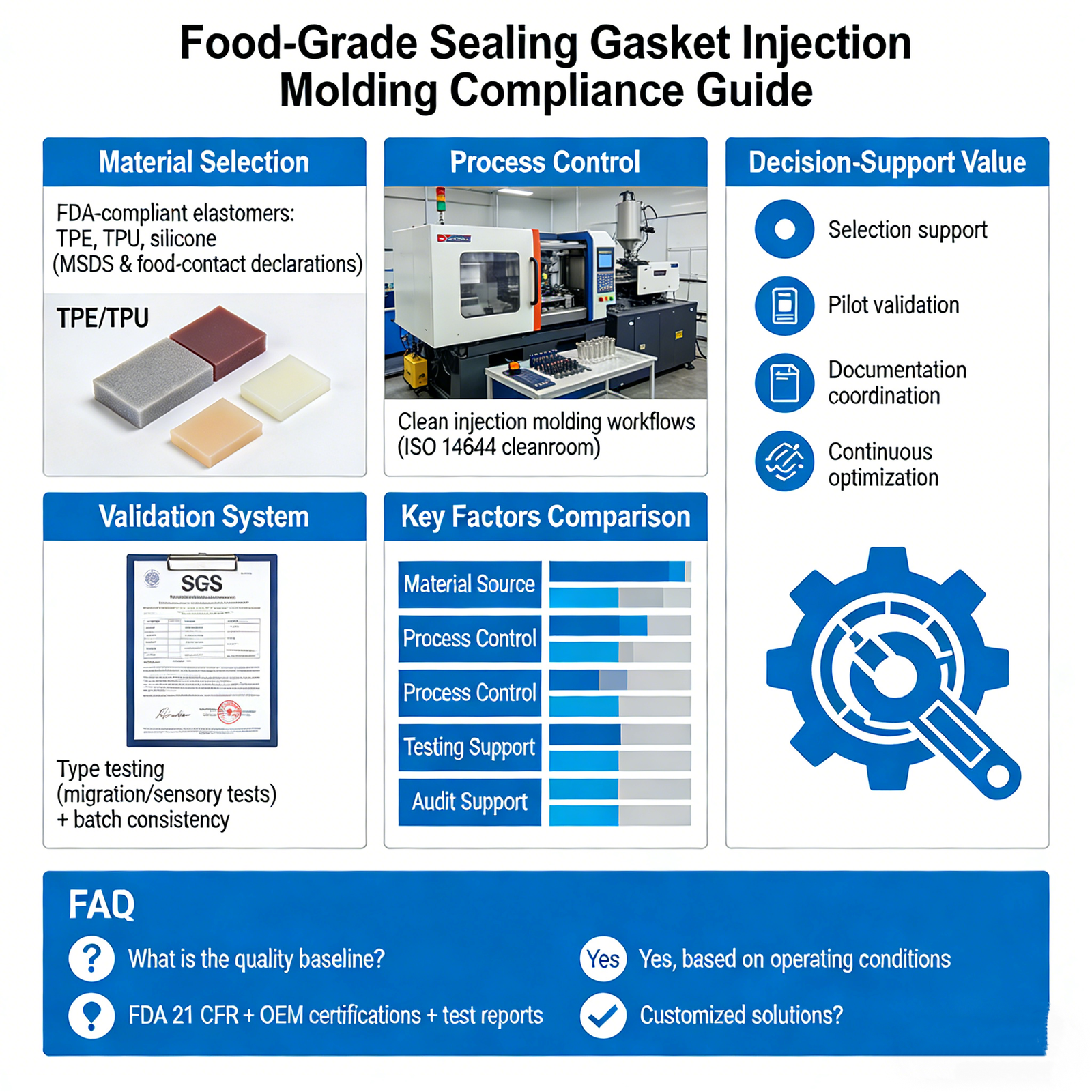

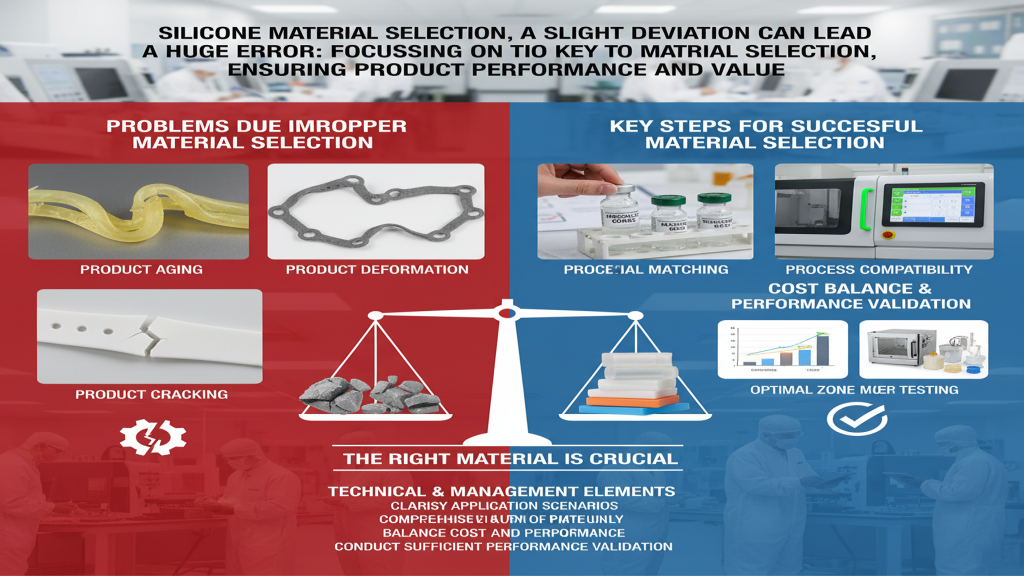

What problems arise from improper material selection?

The formulation of silicone determines its transparency, flexibility, and durability. If the wrong material is chosen, products may quickly age or deform in real use. Companies should always align materials with application scenarios before production.

- Material Matching: Select silicone formulations according to application environments.

- Process Compatibility: Ensure silicone works with equipment and mold requirements.

- Cost Balance: Find the right point between performance and cost.

- Performance Validation: Verify stability through small-batch testing.

😊 The right material is the first step to avoid traps.

How does mold design error affect molding results?

Mold structure directly impacts accuracy and demolding performance. Poor mold design can cause bubbles, flash, or dimensional deviations. Early-stage considerations such as gate location, runner layout, and cooling systems are essential.

- Professional Design: Use 3D modeling and flow analysis to prevent risks.

- Exhaust Optimization: Add proper venting structures into the mold.

- Precision Guarantee: Machining accuracy defines product consistency.

- Maintenance Friendly: Good design reduces future repair costs.

🔧 Proper mold design is the safeguard of product quality.

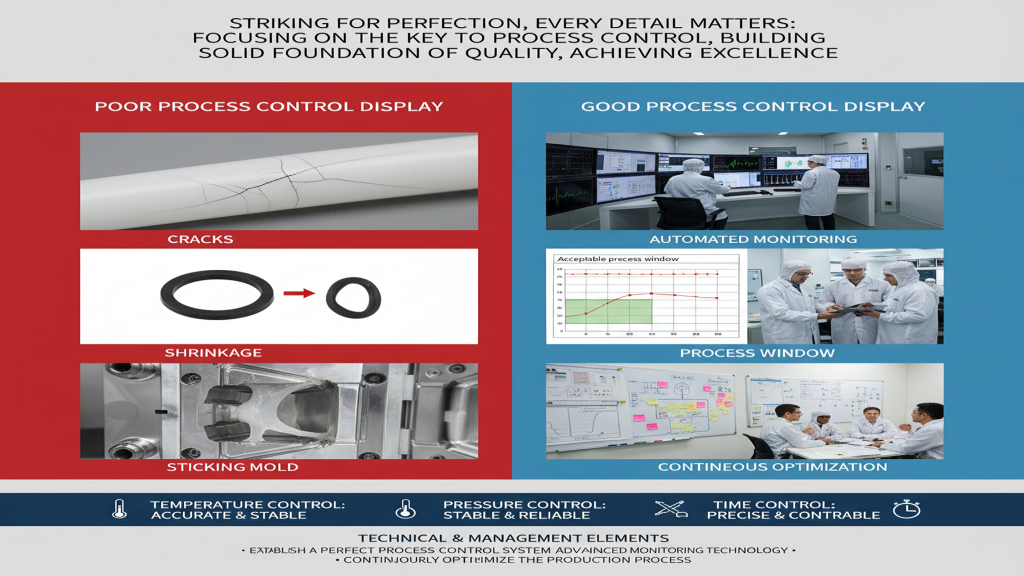

What risks result from poor process control?

Parameters such as temperature, pressure, and time determine product quality. If not well controlled, defects like cracks, shrinkage, or sticking molds may occur. Companies should standardize processes and monitor parameters in real time.

- Automation Monitoring: Use sensors and software to control fluctuations.

- Process Window: Establish stable ranges suitable for material properties.

- Operator Training: Ensure staff handle abnormalities effectively.

- Continuous Optimization: Regularly review parameters to improve yield.

⚙️ Stable process control is the foundation of mass production success.

Common Defects in Silicone Injection Molding

| Defect Type | Root Cause | Impact | Solution |

|---|---|---|---|

| Bubbles | Poor venting | Surface issues | Optimize mold venting |

| Flash | Loose mold | Extra trimming | Improve mold accuracy |

| Shrinkage | Uneven cooling | Dimensional error | Adjust cooling system |

| Sticking | Excess heat | Demolding issues | Optimize process setup |

Partnering with experienced experts helps identify and avoid these traps quickly, contact us.

How to ensure long-term project stability?

From initial planning to mass production, every stage requires systematic control. Standardized processes and quality monitoring help achieve sustainable growth. Working with capable suppliers allows companies to focus on market competition.

1.Stable Supply Chain: Secure long-term raw material availability.

2.Quality Tracking: Establish thorough testing and traceability systems.

3.Tech Upgrades: Adopt new processes to stay competitive.

4.Customer Support: Provide responsive after-sales and engineering assistance.

Conclusion

Avoiding silicone molding traps depends on full control over materials, molds, and processes. Only with systematic management can projects run stably and efficiently. To further minimize risks, companies should rely on professional partners for both knowledge and technology. Ultimately, this strengthens product quality and accelerates competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!