Introduction

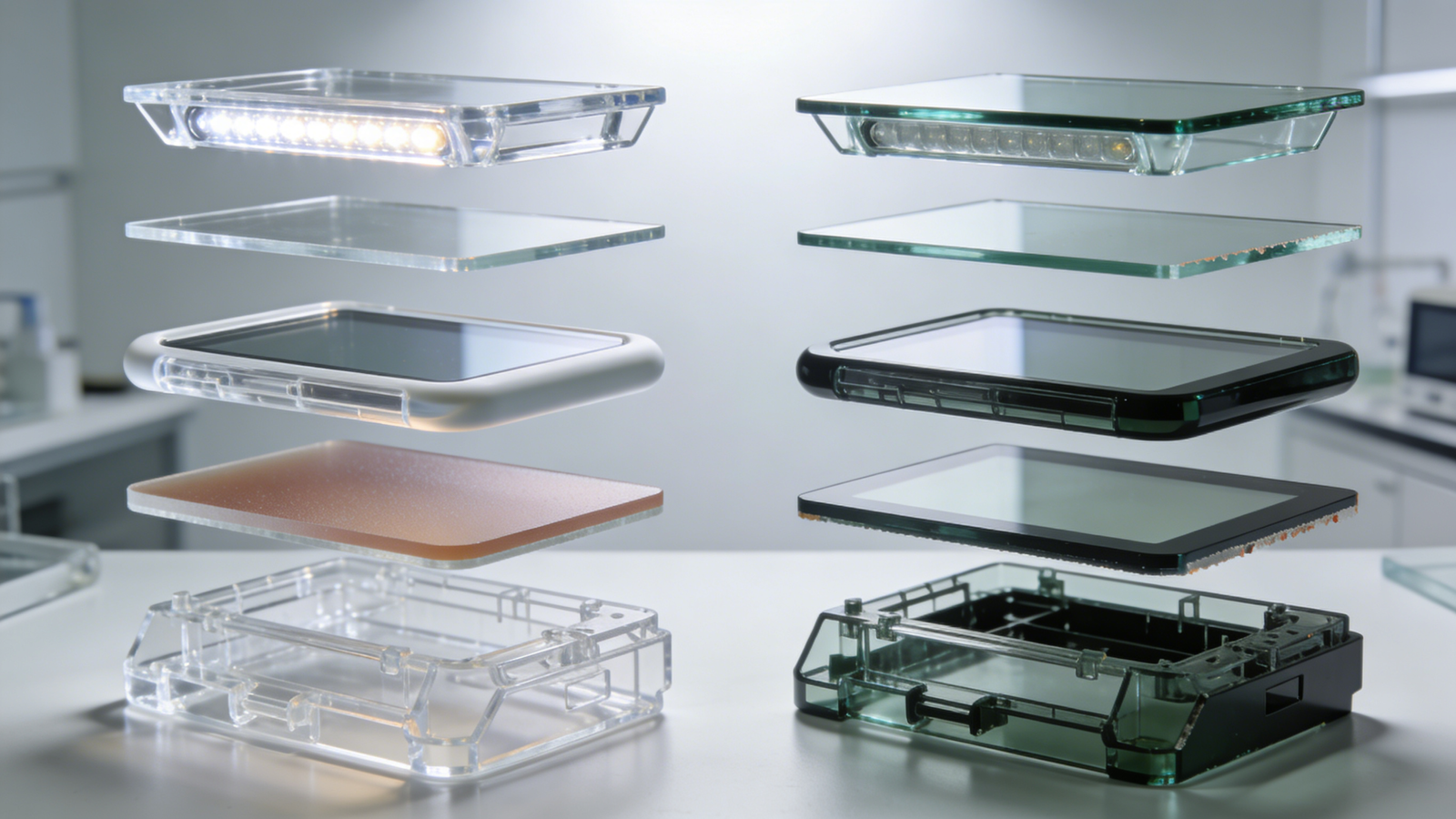

Inverter insulation pads play a critical role in high-voltage protection, and optimized injection molding directly affects their breakdown voltage performance and long-term reliability. Material selection, mold design, and production environment work together to determine whether the final product can consistently achieve insulation standards above 10kV. In Xiamen Ruicheng's injection molding practice, full-process control ensures every insulation pad performs reliably, providing a foundation for high-voltage inverter operation.

Precision injection molding is not just a manufacturing process; it is core to product performance and customer trust. Through material modification and injection process optimization, inverter insulation pads consistently deliver high-voltage isolation in real-world applications. Accurate control of melt flow and cooling uniformity is key to achieving 10kV breakdown voltage.

Does material selection affect breakdown voltage?

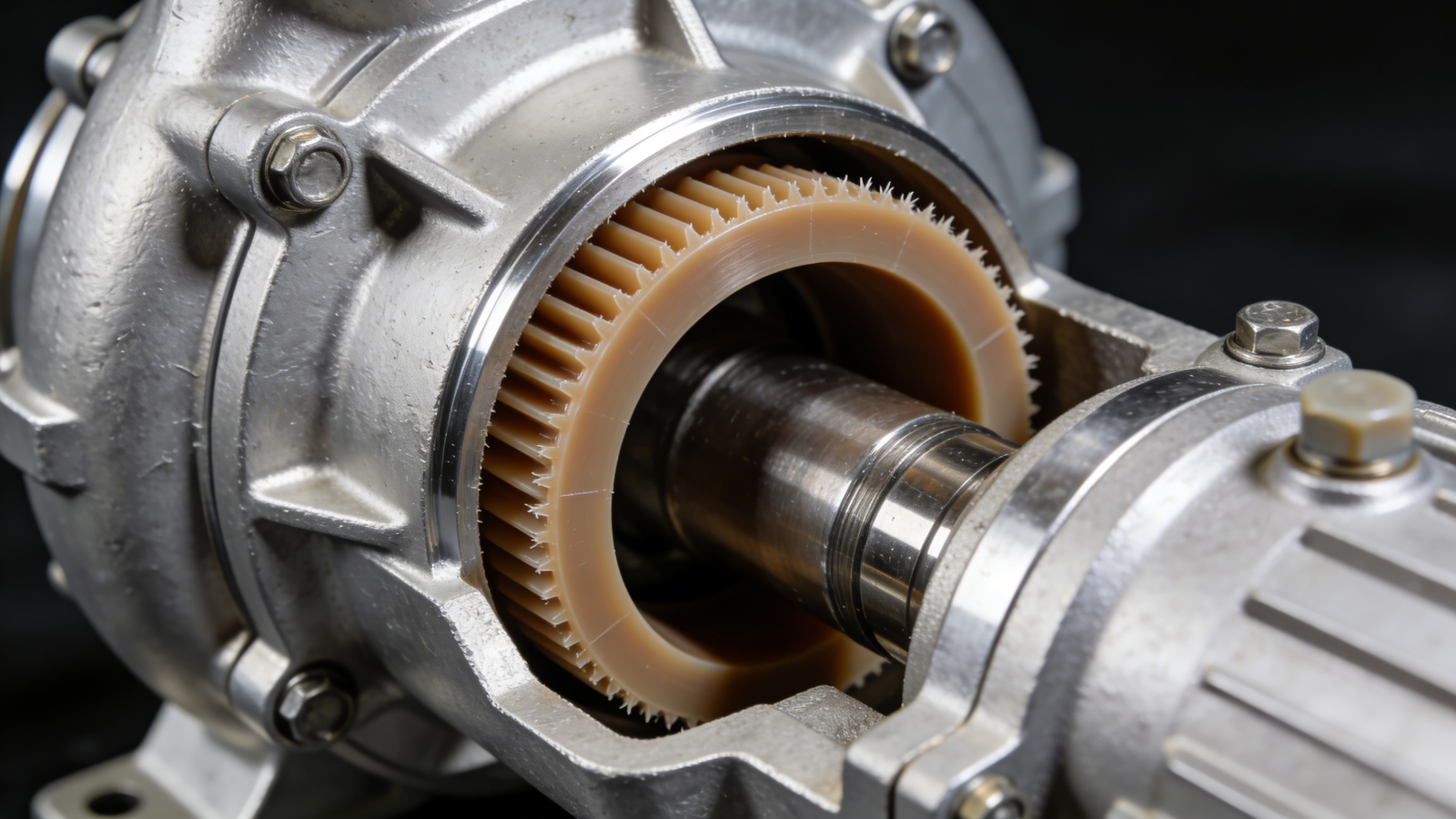

Selecting the right insulation material is the first step for injection-molded inverter pads to reach 10kV breakdown voltage. High-performance polyamide and polycarbonate, enhanced with flame retardants and fillers, can significantly improve breakdown strength. The intrinsic dielectric strength of the material directly determines the high-voltage tolerance of the final product. Uniform material distribution and degassing reduce microbubble defects that affect electrical performance.

Material modification: Adding high-voltage enhancing fillers improves insulation performance.

Particle size control: Ensures uniform distribution and prevents local breakdown.

Flame retardant addition: Enhances material safety factor and long-term stability.

Degassing process: Minimizes micro-voids during molding to ensure voltage tolerance.

😊 Choosing the right material and optimizing processing is essential to achieve 10kV breakdown voltage.

How does injection molding affect insulation pad performance?

Mold design and injection molding process parameters directly influence inverter insulation pad breakdown voltage performance. Melt temperature, injection speed, and hold pressure determine material flow uniformity. Uneven cooling or high shear rates can cause local defects, reducing breakdown voltage. Xiamen Ruicheng optimizes injection parameters and mold venting design to balance overall pad performance and improve high-voltage stability.

Melt temperature control: Precisely manage temperature to avoid local overheating.

Injection speed: Ensures uniform flow and reduces internal stress.

Hold pressure optimization: Prevents material shrinkage and microvoid formation.

Mold venting: Ensures timely air removal to avoid breakdown defects.

⚡ Precise injection molding parameters directly determine whether insulation pads meet high-voltage standards.

How to ensure consistent batch performance?

Even with optimized materials and processes, batch production can still show performance variation, affecting the 10kV breakdown voltage. Xiamen Ruicheng implements full-process quality control, including CMM inspection, dielectric testing, and online monitoring to ensure consistency across batches. Production environment control and mold maintenance minimize batch-to-batch differences and achieve reliable mass production.

Online inspection: Monitors key dimensions and defects in real time.

Dielectric testing: Random checks for breakdown voltage in each batch.

Environmental control: Strictly manage temperature, humidity, and cleanliness.

Mold maintenance: Regular inspection ensures stable production output.

📦 Batch stability is the guarantee of reliability for high-voltage insulation pads.

Xiamen Ruicheng Product Comparison Table

| Model | Material Type | Injection Features | Breakdown Voltage | Application |

|---|---|---|---|---|

| RC-IP10 | PA66 + GF | Precision injection + mold temperature control | 10kV | PV Inverters |

| RC-IP12 | Modified PC | High-pressure injection + venting optimization | 11kV | Industrial Inverters |

| RC-IP15 | PA6 + Flame Retardant | Hold pressure optimization + uniform cooling | 10kV | Energy Storage Inverters |

| RC-IP18 | PC/ABS blend | Homogenized melt + online inspection | 10.5kV | Transportation Energy |

Ensure consistent high-voltage performance across every batch, contact us

Design Optimization Recommendations

Insulation pad design should balance electrical and mechanical performance. Uniform thickness, smooth radius transitions, and rib structures are key to enhancing breakdown voltage. Proper mold flow analysis and design optimization significantly reduce defect rates.

1.Uniform thickness: Ensures even electric field distribution.

2.Smooth radius transitions: Reduces local electric field concentration.

3.Rib structure design: Increases mechanical strength without compromising insulation.

4.Mold flow simulation: Predicts potential defects and optimizes molds in advance.

FAQ

Question 1: What are the core quality standards for inverter insulation pads?

Answer: Key dimension tolerance ±0.05mm, dielectric strength ≥10kV, full-process quality control ensures stability.

Question 2: How to engage with inverter insulation pad suppliers and get a quote?

Answer: Submit CAD/STEP drawings, receive DFM evaluation and accurate quote within 12 hours, free sample support provided.

Question 3: What is the minimum order quantity and delivery lead time?

Answer: Small batch MOQ starts from 100 pcs, unlimited for large batch; sample 3-5 days, mass 10-15 days, expedited orders available.

Conclusion

Achieving 10kV breakdown voltage for inverter insulation pads requires optimized material selection, injection molding processes, and batch quality control. Xiamen Ruicheng leverages full-process control and design optimization to deliver reliable high-voltage insulation solutions. Precision injection molding combined with online quality monitoring ensures high-performance, high-reliability mass production, providing comprehensive support for customer decision-making.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!