The ultimate impact resistance of PC is a complex topic, professionally determined by materials, structure, and testing standards. It cannot be simply summarized as "durable." To understand the "hard power" of PC, one must analyze how it resists sudden external forces.

So, what factors are at play behind the scenes? The chassis material is one, but more critical is the internal design. The fixing method of precision components and the application of cushioning materials are silently resisting impact. Professional testing within the industry is the gold standard for measuring the impact resistance of PCs.

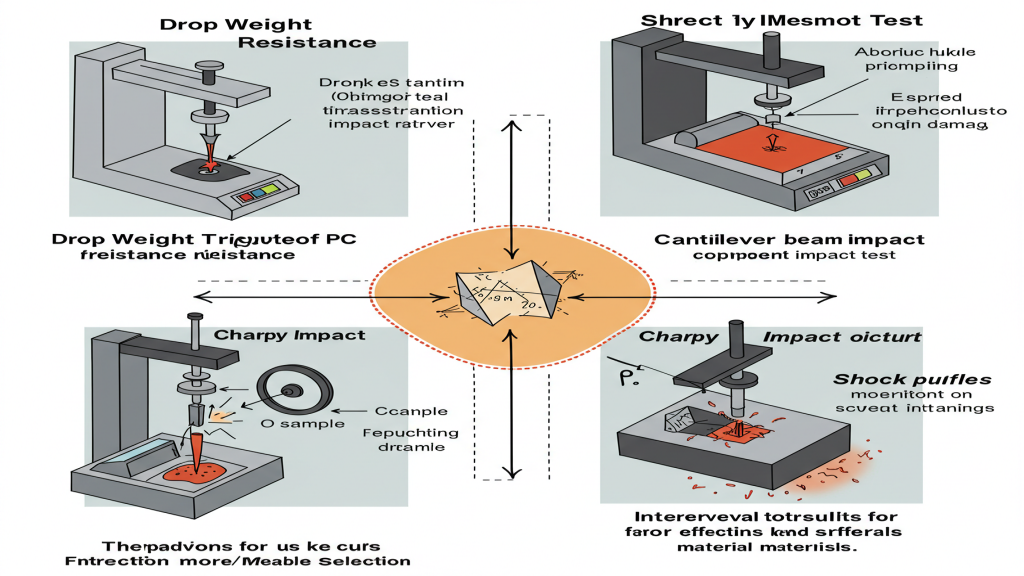

What professional tests are there for PC impact resistance?

In the world of engineering plastics, impact resistance is a key indicator of material reliability and durability. So, for injection molding materials commonly used in PC cases and internal components, what professional testing methods can accurately assess their ability to resist sudden external forces? How do these tests help us choose more "robust" materials?

- Drop Weight Impact Test: Simulates accidental drops and measures the energy required to fracture the material.

- Izod and Charpy Impact Tests: Evaluates material toughness and reflects the strength when subjected to impact. (Izod impact test is a cantilever beam impact test, while Charpy impact test is a simply supported beam impact test.)

- Drop Test: Simulates actual drop scenarios and examines the overall damage resistance of the PC.

- Shock Pulse Test: Simulates short-term, intense impacts and assesses resistance in environments such as transportation.

What designs and technologies can enhance PC impact resistance?

To make PCs excel in "head-to-head" tests, engineers have racked their brains. From the robust selection of materials for the outer shell to the ingenious layout of the internal structure, and the addition of various innovative technologies, all are aimed at creating a stronger "skeleton" and "armor" for the PC to cope with various accidental impacts in daily use.

- High-Strength Toughness Materials: Select more robust engineering plastics to absorb and disperse impact forces.

- Shock-Absorbing Fixing Design: Secure internal components, isolate impact and vibration, and prevent loosening and damage.

- Structural Reinforcement Integration: Enhance body strength and resistance to deformation, reducing the risk of structural separation.

- Special Coating Treatment: Increase the hardness and wear resistance of the outer shell, resisting minor scratches and impacts.

What are the differences in impact resistance among different types of PCs?

Even though they are all PCs, different types of products often exhibit vastly different levels of "resistance" when facing accidental impacts. From thin and light portable laptops to rugged industrial-grade tablets and desktop computers with relatively fixed internal structures, their design concepts and application scenarios determine the differences in their impact resistance.

- Laptops vs. Desktops: Laptops are more portable but often more fragile, with high-end models offering enhanced protection; desktops are used in a fixed location with lower impact risks, but attention should be paid to internal connections.

- Consumer-Grade vs. Industrial-Grade/Ruggedized PCs: Consumer-grade PCs prioritize lightness, thinness, and aesthetics, with weaker impact resistance; industrial-grade/ruggedized PCs are specifically designed for harsh environments and possess extremely high impact resistance.

- All-in-One vs. Separate Desktop PCs: All-in-one PCs have a higher overall risk of impact, while impacts on separate PCs may only affect certain parts; specific design determines impact resistance.

- Tablets/2-in-1 Devices vs. Traditional Laptops: Tablets/2-in-1s are often hand-held and prone to drops, with some models featuring enhanced protection; traditional laptops have screen protection when closed, but the hinge is a weak point.

Comparison of impact resistance of different types of PC

| Feature | Standard PC | Impact-Resistant Modified PC | Thermally Modified PC | EMI Shielding Modified PC | Flame-Retardant Modified PC | Weather-Resistant Modified PC | Lightweight Modified PC | Anti-Bacterial Modified PC | Scratch-Resistant Modified PC | Biocompatible Modified PC |

|---|---|---|---|---|---|---|---|---|---|---|

| Outer Shell Material | Regular Engineering Plastics (ABS, PC, etc.) | High-Strength/Toughness PC Composites (Alloys, Reinforced) | High Thermal Conductivity PC Composites | Conductive Filler PC Composites (Metal Powders, etc.) | Flame-Retardant PC Materials (UL94 V-0 Compliant) | Weather-Resistant PC Materials (Anti-UV, Humidity) | Lightweight High-Strength PC Composites (Carbon Fiber Reinforced, etc.) | Anti-Bacterial Agent Added PC Materials | High Hardness Coating or Special Surface Treatment PC | Biocompatible PC Materials |

| Internal Structure | Standard Layout, Basic Fixing | Strengthened Fixing, Shock-Absorbing Materials, Key Component Protection | Optimized Airflow, Potential Use of Thermal Interface Materials | Shielding Design, Reduced EMI Leakage and Intrusion | No Special Structural Requirements, but Material Must Be Flame-Retardant | Potentially Better Sealing to Prevent Environmental Impact | Compact Structure, Lightweight Design | No Special Structural Requirements | Surface Hardening Treatment, Reduced Scratch Risk | Structure Designed According to Medical Device Needs |

| Key Characteristics | Meets Daily Usage Needs | Withstands Drops, Impacts, and Other Accidents | Efficient Heat Dissipation, Stable Operation Under High Load | Protects Internal Components from EMI, Reduces Self-Emitted Radiation | Does Not Easily Ignite or Spread Fire | Long-Term Stable Operation in Outdoor or Harsh Climates | Lightweight and Portable While Maintaining Strength | Inhibits Bacterial Growth, Maintains Device Hygiene | Surface is Not Easily Scratched, Maintains Appearance | Non-Toxic and Harmless to the Human Body, Does Not Cause Adverse Reactions |

| Application Areas | Office, Entertainment, Learning, etc. | Industrial, Military, Outdoor Work, Transportation in Harsh Environments | Gaming, High-Performance Computing, Servers Requiring Efficient Cooling | Medical, Scientific Research, Military, Communications Where EMI is a Concern | Industrial Control, Public Safety, Medical Equipment Requiring Fire Safety | Outdoor Displays, Vehicle-Mounted Devices, Aerospace Where Long-Term Exposure is Expected | Mobile Office, Drones, Wearable Devices Sensitive to Weight and Size | Medical, Educational Institutions, Public Places Where Hygiene is Important | Frequently Touched or Easily Scratched Devices, Such as Tablets, Touchscreens | Medical Implants, Medical or Scientific Devices in Direct Contact with the Human Body |

| Cost | Relatively Low | Generally Higher | Potentially Higher | Generally Higher | Potentially Higher | Potentially Higher | Generally Higher | Potentially Higher | Potentially Higher | Generally Higher |

Maintenance to Reduce Product Impact Damage

Even if a PC has a robust "physique," improper use and maintenance can make it vulnerable to accidental impacts. Understanding some simple maintenance tips and precautions is like adding an invisible protective shield to your device, which can greatly reduce the risk of impact damage and extend the PC's lifespan.

1.Proper Carrying and Placement: Use protective measures, place the PC securely, and avoid accidental drops.

2.Avoid Violent Vibrations and Impacts: Handle with care, secure during transportation, and reduce vibration and collision.

3.Regular Cleaning and Inspection: Maintain good heat dissipation, check for secure connections, and maintain device stability.

4.Develop Good Usage Habits: Operate gently, plug and unplug properly, and avoid improper behavior that can cause damage.

Conclusion

The impact resistance of a PC is a comprehensive reflection of various factors, involving material selection, internal design, and professional testing. Different types of PCs exhibit varying performance in this regard, and modified PCs are enhanced for specific needs. User habits and maintenance practices are also crucial; proper carrying, avoiding violent impacts, regular cleaning and inspection, and gentle operation can all effectively reduce the risk of damage from impacts.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!