Introduction

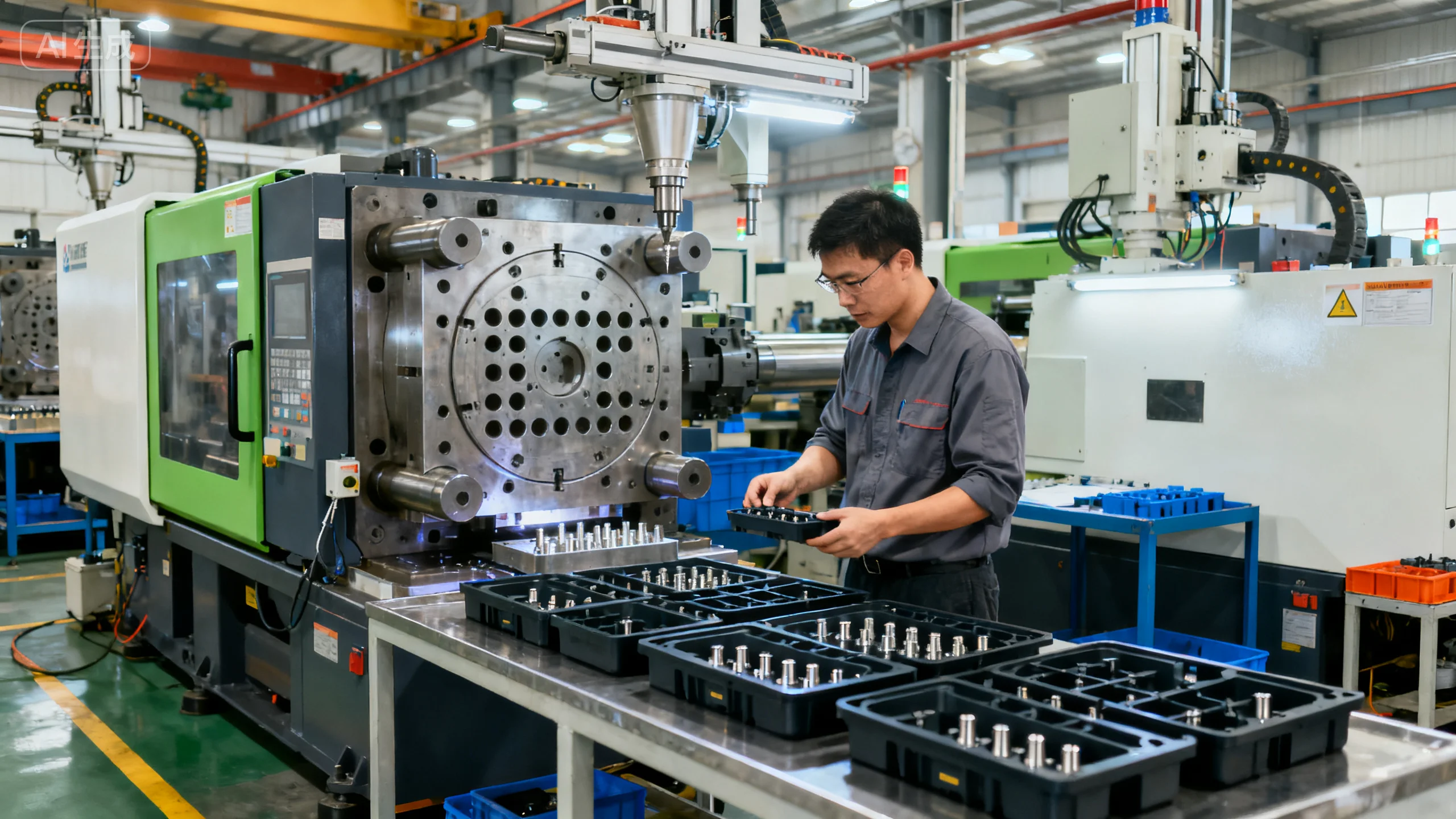

Thermal decomposition temperature is a key parameter that defines the molecular stability of plastics. When the processing temperature approaches or exceeds this point, the material’s properties degrade rapidly. Stable control of decomposition temperature is the foundation for consistent product quality. During injection molding, temperature not only affects the melt flow but also determines the surface finish and structural integrity of the product.

For manufacturers, optimizing decomposition temperature control is crucial to improve production efficiency and yield. Excessive temperature causes molecular chain breakage, while insufficient heat reduces fill quality. By applying precise temperature management strategies, manufacturers can achieve a balance between cost and quality.

What defects occur when the decomposition temperature is too high?

When the thermal decomposition temperature is neglected or set too high, polymer molecules undergo degradation, releasing gases that create bubbles or burn marks on the surface. This not only affects appearance but also significantly weakens mechanical strength. If the temperature control system reacts slowly, defect rates will continue to rise.

- Material Carbonization Risk: Excessive temperature breaks polymer chains, forming carbonized residues.

- Temperature Control Deviation: Slow thermocouple response leads to uncontrolled melt heating.

- Residual Gas Formation: Entrapped bubbles create voids inside parts.

- Insufficient Mold Cooling: Local overheating accelerates degradation and dulls the surface.

🔥 Controlling decomposition temperature is the first step in preventing surface and structural defects.

What happens when the decomposition temperature is too low?

When the decomposition temperature is set too low, the material is under-melted, resulting in short shots, visible weld lines, and internal stress. Although low temperatures reduce degradation, they compromise melt flow and part fusion. This directly impacts mold filling performance and the overall structural integrity of molded parts.

- Insufficient Melting Risk: Poor melt flow leads to incomplete filling.

- Abnormal Molecular Orientation: Under-melted areas generate localized stress.

- Increased Weld Lines: Poor fusion at flow junctions.

- Longer Cycle Times: Higher injection pressure needed to compensate for low temperature.

⚙️ Setting the right minimum temperature ensures stable flow and strong bonding.

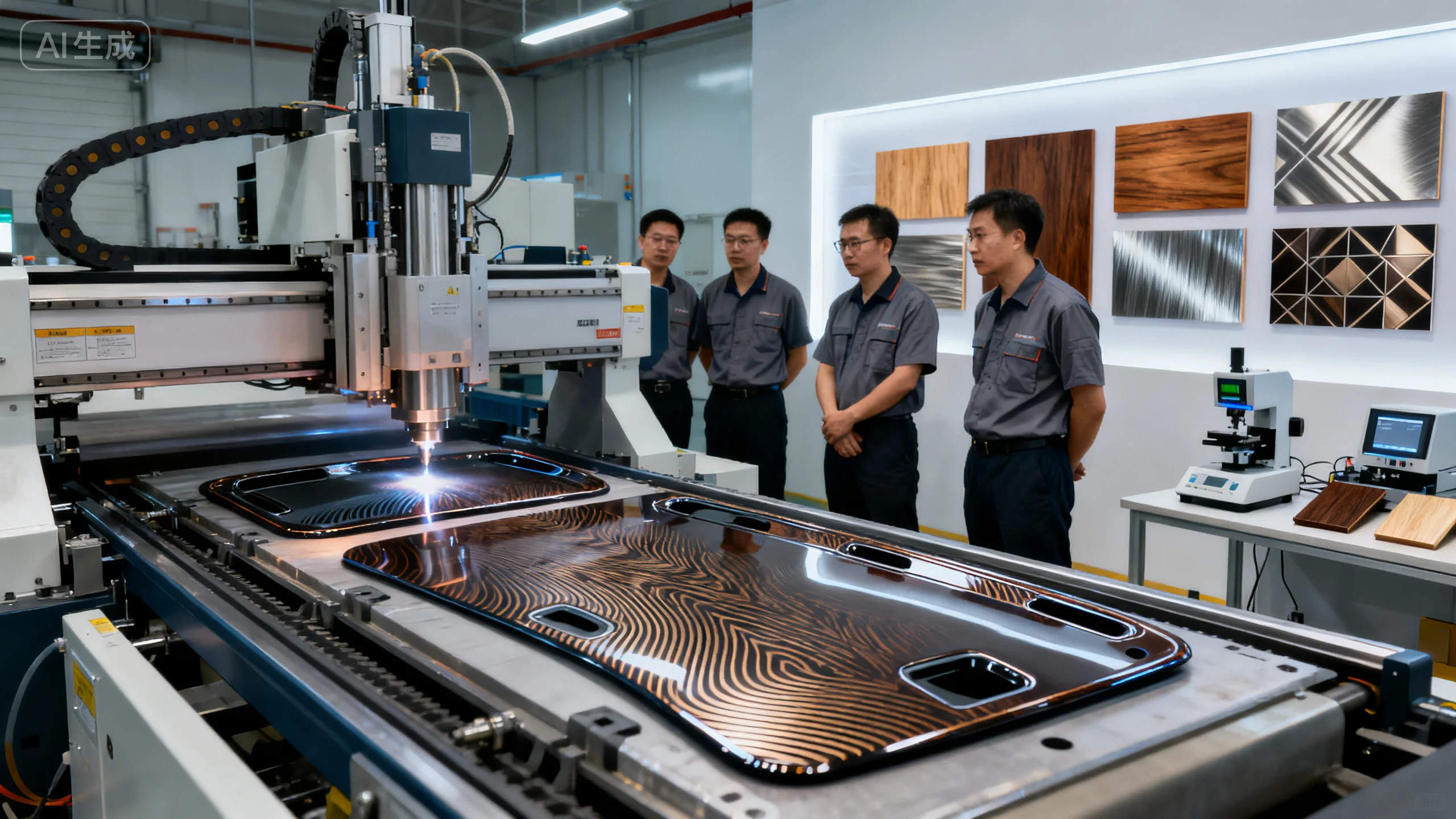

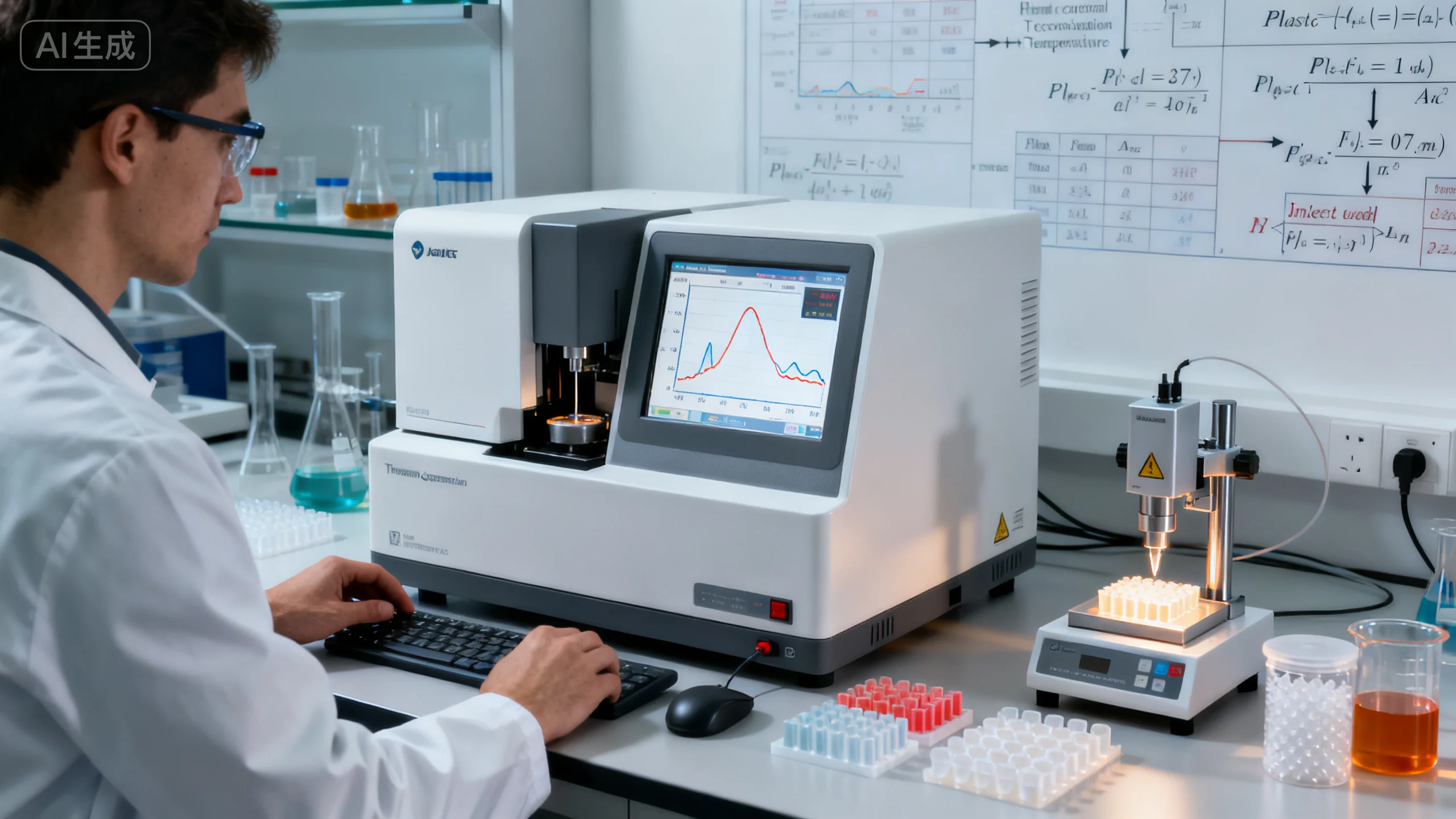

How can manufacturers control decomposition temperature in production?

Controlling decomposition temperature in injection molding depends on both equipment settings and material compatibility. Through precise thermal control, real-time monitoring, and data-driven analysis, degradation can be effectively prevented. Especially in large-scale production, maintaining temperature stability directly impacts overall yield consistency.

- Real-Time Temperature Control: Smart sensors automatically adjust melt temperature.

- Material Drying Management: Prevents hydrolysis-induced thermal degradation.

- Zoned Heating Control: Keeps temperature uniform across barrel sections.

- Routine Calibration: Ensures thermocouple and heater accuracy over time.

🌡️ Stable temperature control is the foundation for consistent mass production.

Impact of Decomposition Temperature on Molding Efficiency

| Parameter | High-Temp Decomposition | Low-Temp Molding | Optimal Control | Fluctuating Conditions |

|---|---|---|---|---|

| Surface Quality | Bubbles, burn marks | Visible weld lines | Smooth, uniform | Unstable |

| Yield Rate | ↓ 30% | ↓ 15% | ↑ 20% | Highly variable |

| Flow Performance | Over-fluid | Poor flow | Balanced | Unpredictable |

| Mold Maintenance | High frequency | Medium | Low | High |

Want to improve your injection molding yield through temperature optimization? contact us today for tailored engineering solutions!

Expansion

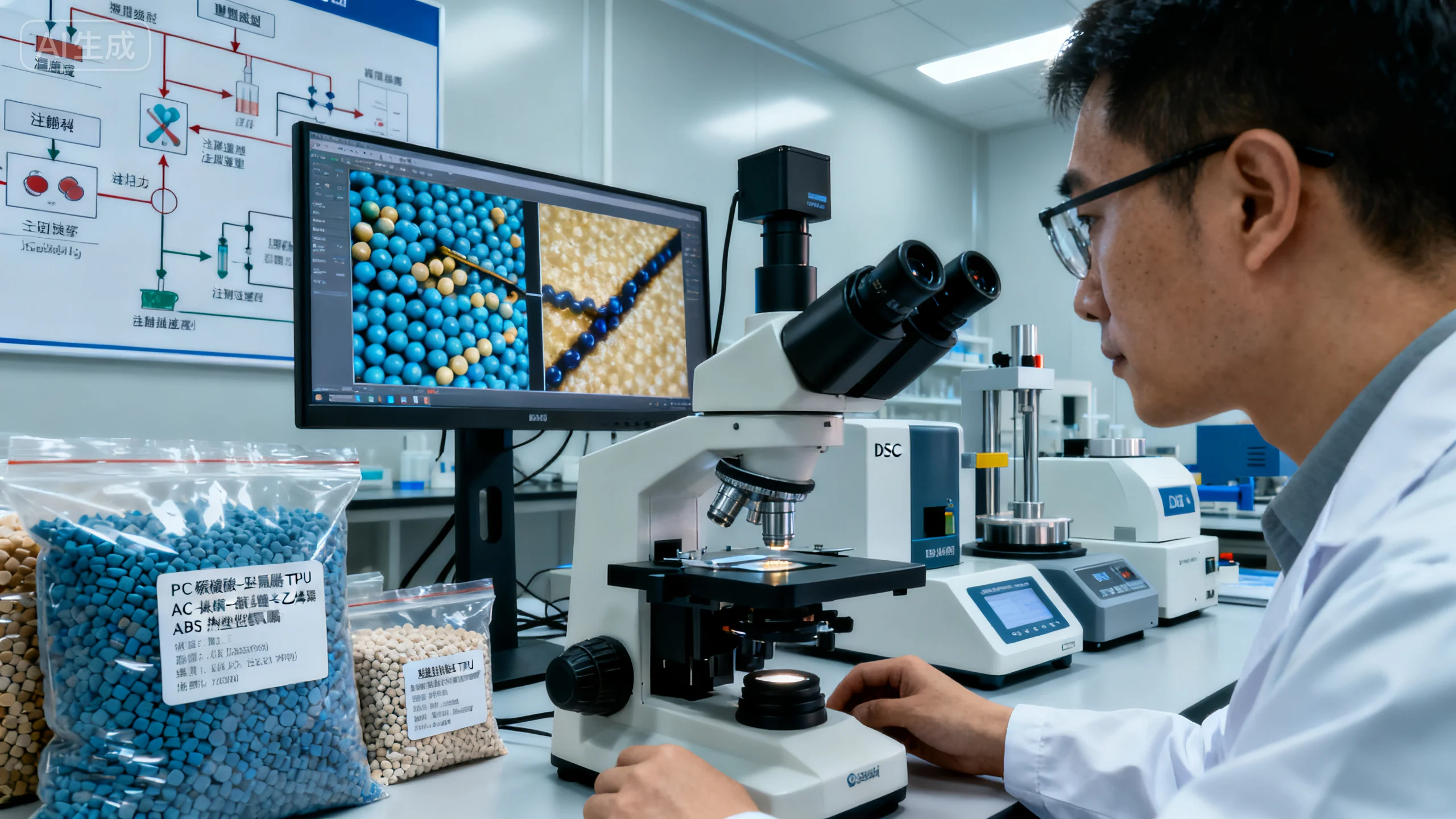

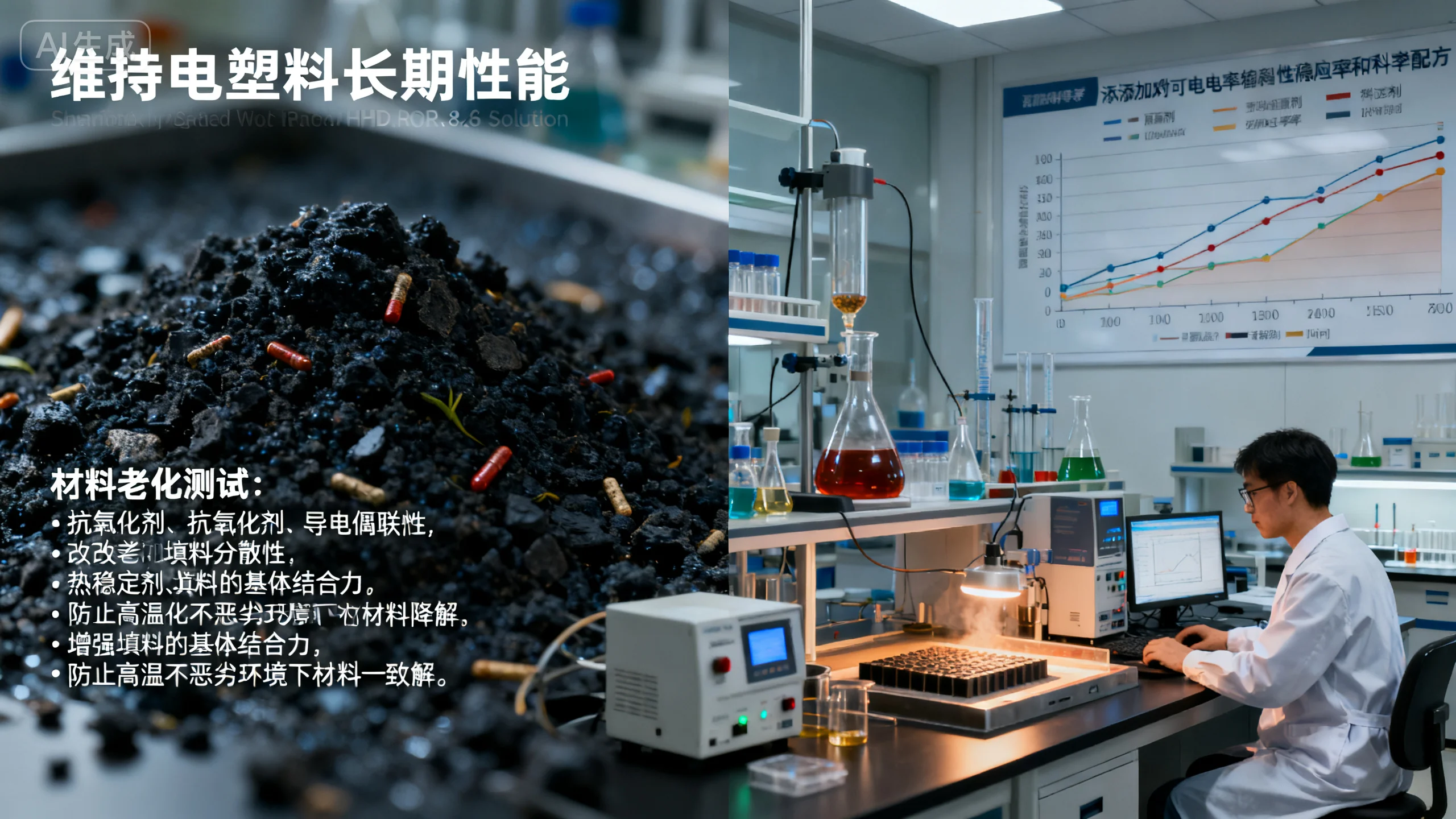

Different plastics require unique decomposition temperature management strategies. Thermoplastics and thermosets exhibit completely different thermal degradation behaviors, demanding individualized control curves. Moreover, AI and IoT integration enables predictive temperature control, minimizing human error in real-time production.

1.Multi-material Process Integration: Each resin blend requires independent thermal control.

2.Data-Driven Modeling: Analytical optimization of temperature response time.

3.Automatic Alarm Systems: Prevents overheating and batch rejection.

4.Cloud-Based Monitoring: Enables live temperature tracking across production lines.

Conclusion

Thermal decomposition temperature is the “invisible key” behind injection molding yield. By maintaining accurate temperature control, manufacturers can enhance yield, extend mold life, and improve machine stability. When thermal management aligns with material behavior, both efficiency and quality rise together.Ultimately, a robust temperature control system becomes a competitive advantage in high-precision molding.

For expert assistance in implementing temperature control for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!