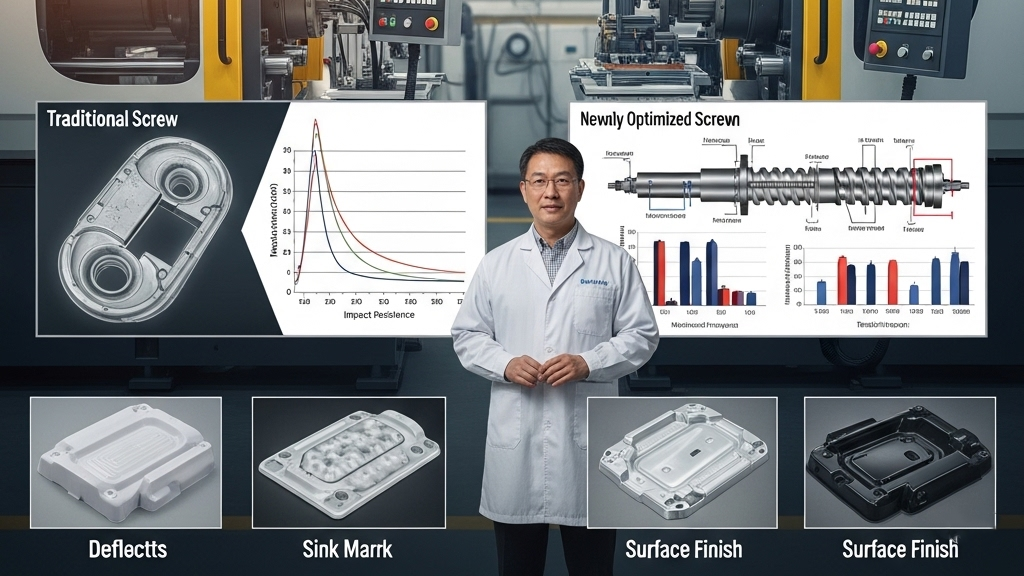

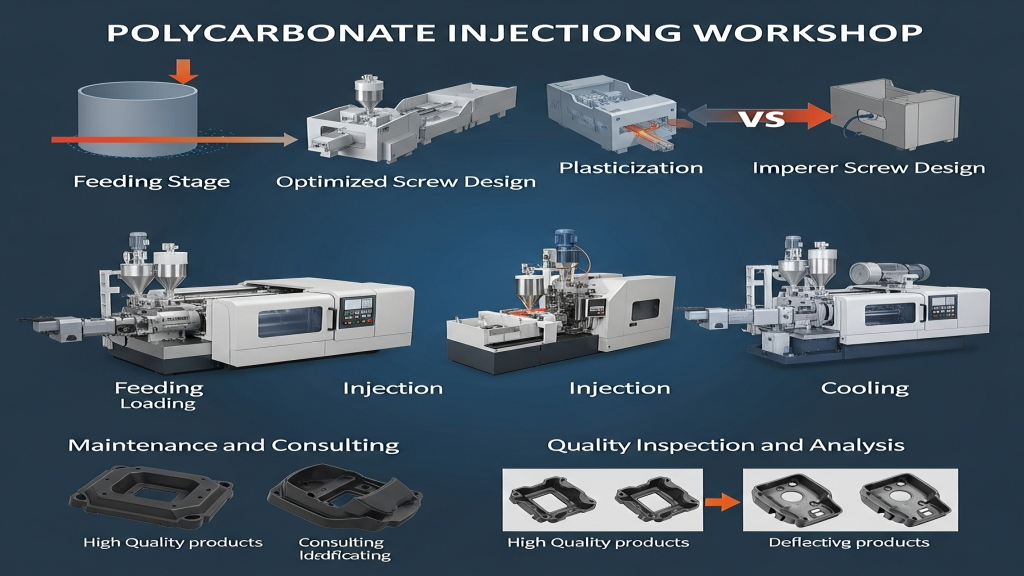

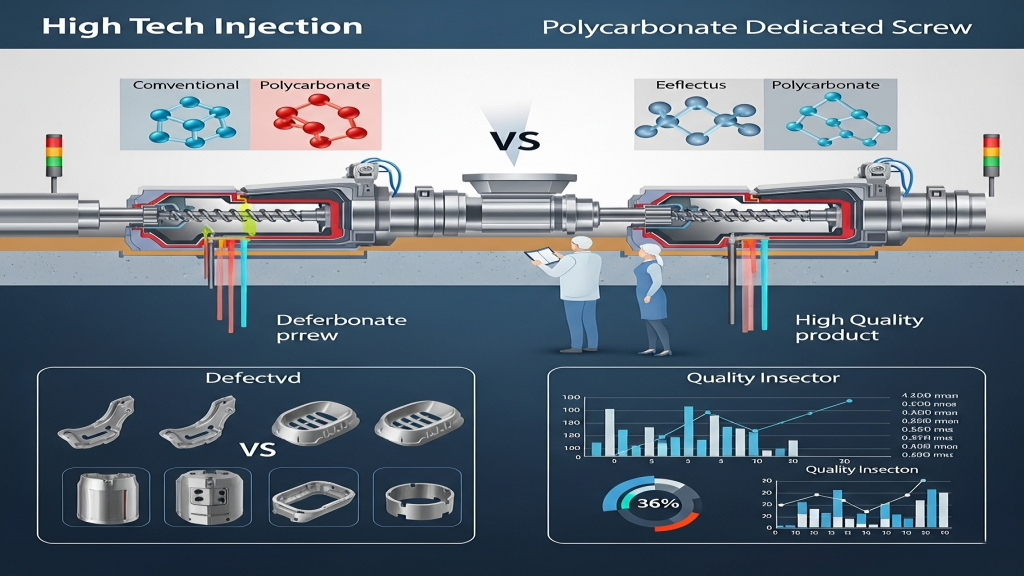

In the injection molding industry, the screw design plays a crucial role in the final product quality and production efficiency. Particularly in the injection molding process of polycarbonate, the design and selection of screws directly affect the molding quality, mechanical performance, and surface finish of the products. The quality of screw design determines the stability of the injection molding process and the consistency of the product.

As polycarbonate is widely used in various industries as an engineering plastic, the injection molding process requires more precise control. A well-designed screw can significantly improve production efficiency and reduce scrap rates, thus lowering production costs and enhancing overall commercial competitiveness.

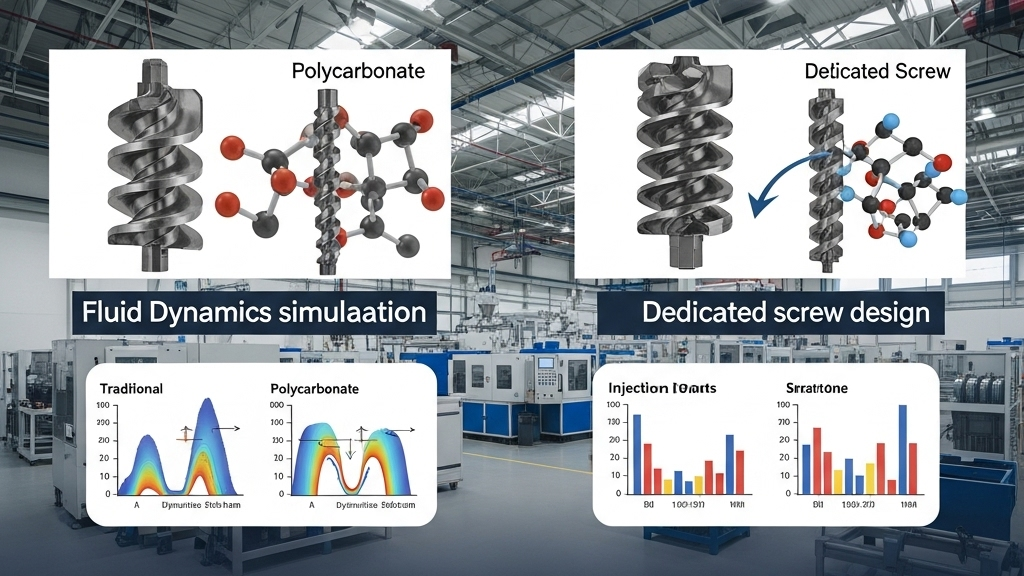

How does screw design affect polycarbonate flowability?

The rationality of screw design determines the flowability and filling uniformity of polycarbonate during the injection molding process. The screw length, thread shape, and pitch can all affect the melting and plasticizing effects of polycarbonate. An ideal screw design ensures uniform flowability of polycarbonate, thus avoiding molding defects.

- Screw Length and Flowability: Affects the uniformity of polycarbonate melting.

- Thread Shape: Affects the plasticizing effect of polycarbonate.

- Pitch Design: Optimizing pitch improves polycarbonate flowability.

- Temperature Distribution: Affects polycarbonate melting uniformity.

How does screw design affect polycarbonate surface quality?

Surface quality is a key property of polycarbonate injection molded parts, and screw design has a profound impact. Improper screw design can lead to overheating, oxidation of materials, and affect surface finish. A proper screw design helps reduce surface defects and ensures high-quality appearance of polycarbonate parts.

- Melt Temperature Control: Prevents overheating and surface defects.

- Material Flow Consistency: Uniform flow reduces surface blemishes.

- Plasticization Rate: Affects surface gloss and detail.

- Cooling Rate: Directly affects surface flatness.

How does screw design affect polycarbonate mechanical properties?

Polycarbonate's mechanical properties, such as strength, toughness, and impact resistance, largely depend on screw design during the injection molding process. Optimizing screw design can improve the molecular arrangement of polycarbonate, thereby enhancing its performance. Improper screw design may lead to a decline in mechanical performance and an increase in post-production failures.

- Screw Speed: Affects the uniformity of polycarbonate molecular structure.

- Pressure Control: Screw pressure impacts performance.

- Melt Temperature and Cooling: Optimizes material properties.

- Mixing Effect: Enhances polycarbonate's mechanical performance.

Screw design and injection quality

| Parameter | Screw Length | Thread Shape | Pitch Design | Screw Speed |

|---|---|---|---|---|

| Flowability | High | Medium | High | Low |

| Surface Quality | Medium | High | High | Medium |

| Mechanical Properties | High | Medium | Medium | High |

| Molding Stability | High | Medium | Medium | Low |

Proper screw design to improve injection quality

When selecting screw designs, apart from basic parameter adjustments, the characteristics of polycarbonate, such as viscosity and temperature sensitivity, should be considered. A reasonable screw design ensures stable plasticization of polycarbonate and improves production efficiency. This not only enhances the surface quality of injection molded parts but also ensures balanced mechanical performance.

1.Match with Material Properties: Ensure the screw design matches the material.

2.Temperature and Pressure Control: Affects product quality and production efficiency.

3.Regular Inspections and Maintenance: Optimize maintenance to improve screw performance.

4.Professional Consulting Services: Help choose the best screw design.

Conclusion

Screw design has a profound impact on polycarbonate injection molding quality, affecting flowability, surface quality, and mechanical properties. Through proper screw design, businesses can significantly improve molding quality, reduce defects and scrap rates, and enhance production efficiency. Choosing the right screw design is key to enhancing commercial competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!