The demand for polycarbonate lenses in optical applications continues to grow, raising the bar for mold precision and surface quality. As a primary manufacturing method, injection molding relies heavily on mold design. The microstructure of the mold determines light transmission and uniformity.

High polish, precision control, and proper venting form the foundation of a high-quality mold, directly influencing final lens performance. To meet demanding industrial requirements, mold development must be a top priority. Improving mold quality is key to maintaining product competitiveness.

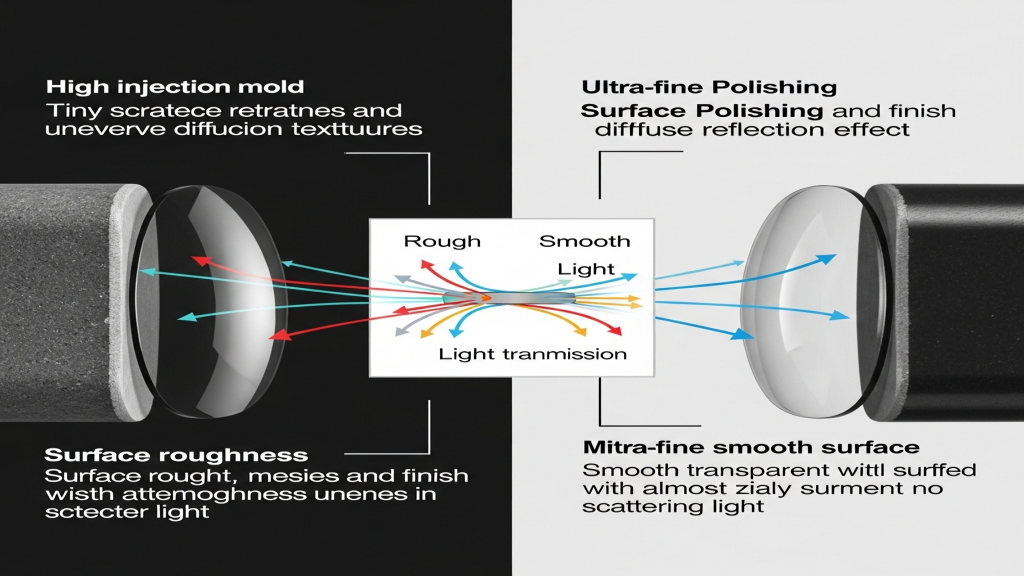

How does mold surface affect optical performance?

The surface roughness of the mold is transferred to the lens during molding, affecting light refraction. In high-precision optical use, even micron-level defects can impair functionality. High-gloss polished molds help ensure consistency and optical quality.

- Ultra-Fine Polishing: Surface finish determines clarity.

- Multi-cavity Optimization: Uniform polishing across cavities reduces variance.

- Coating Enhancement: Pre-coating the mold improves scratch resistance.

- High Temp Material Matching: Mold material affects expansion and precision.

Does temperature control affect light transmission?

Temperature is a crucial, often overlooked, factor in injection molding. Uneven or fluctuating heat causes internal stress, reducing clarity or causing distortion. Temperature uniformity and hot runner systems greatly improve optical consistency.

- Thermal Balance Control: Stable temperature equals stable output.

- Zone Heating Strategy: Localized heat control prevents warping.

- Slow Cooling Application: Reduces stress, boosts clarity.

- Sensor Monitoring Systems: Real-time temp feedback ensures precision.

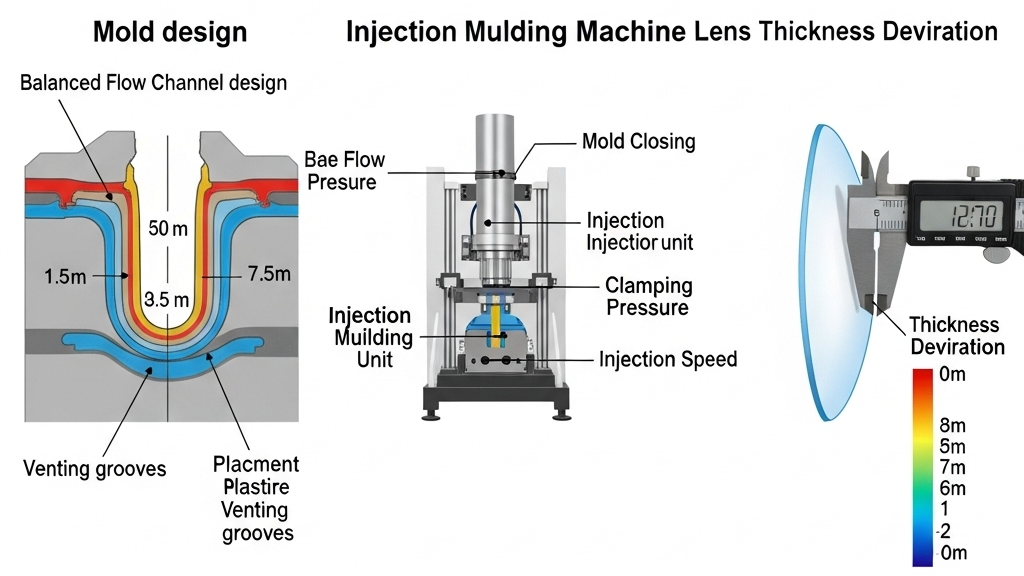

Is lens thickness deviation due to molding or the mold?

In PC lens molding, mold design and injection process are tightly interlinked. Thickness variations often result from misalignment between the two. Poor flow channel design, venting, or clamping can all contribute. Optimizing mold flow channels is key to thickness uniformity.

- Balanced Flow Channels: Central symmetry ensures equal flow.

- Venting Setup: Proper venting reduces short shot and bubbles.

- Clamping Pressure Balance: Prevents flash or warping.

- High Rigidity Design: Resists deformation during cycles.

Comparison of Mold Structures and Optical Impact

| Mold Type | Surface Finish | Heat Control | Precision | Application | Lifespan | Cost | Optical Stability |

|---|---|---|---|---|---|---|---|

| Standard Mold | Polished | Medium | Normal | Industrial | Medium | Medium | Medium |

| Precision Mold | Mirror Finish | High | High | Medical/Optical | Long | High | High |

| Rapid Mold | General | Low | Medium | Prototyping | Short | Low | Low |

| Multi-cavity | Coated | High | High | Mass Prod. | Medium | Med-High | Med-High |

Business Applications

With rising demand in medical, surveillance, and automotive optics, PC lens molding sees vast commercial growth. High-performance molds not only improve optical results but also reduce cycle time. Mold tech upgrades are key to expanding business frontiers.

1.Medical Devices: Clear lenses for surgical magnifiers.

2.Smart Traffic Systems: Better imaging for vehicle cameras.

3.AR/VR Sector: Precision molds boost immersion quality.

4.Security Surveillance: Clear, distortion-free imaging ensured.

Conclusion

The optical performance of polycarbonate lenses is deeply influenced by mold design—every detail from mold texture to thermal strategy affects the result. Companies that master mold precision will lead in high-end optical markets. Investing in high-performance molds is a strategic move for brand strength and market share.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!