Introduction

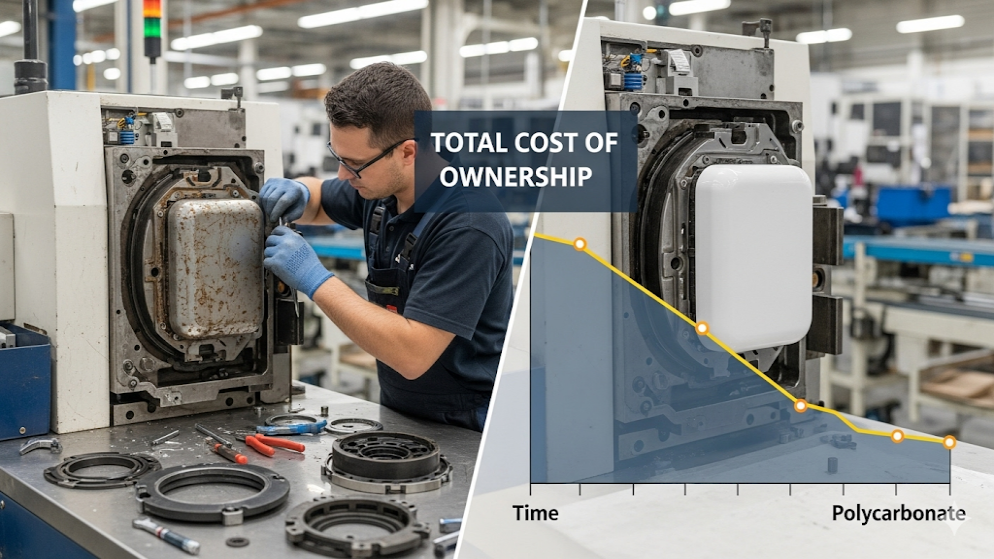

Polycarbonate (PC) durability is not only reflected in its mechanical strength and impact resistance, but also in its ability to reduce maintenance and replacement frequency. It significantly lowers the total cost of ownership over time, enhancing return on investment.

In injection molding, PC’s excellent wear resistance and stability ensure parts remain reliable even in harsh environments. This means that at the design stage, companies can achieve more competitive cost control by choosing PC.

How does PC durability reduce maintenance costs?

The mechanical strength and impact resistance of PC make it less prone to damage during long-term use, reducing replacement expenses. In large-scale injection molding, material selection extends product lifespan and lowers maintenance costs. This not only improves product performance but also creates more value for customers.

- Reduced replacement frequency: PC parts extend equipment life cycles.

- Lower after-sales costs: PC products minimize service-related expenses.

- Enhanced customer satisfaction: Reliable durability drives stronger reputation.

- Optimized long-term investment: Hidden project costs are reduced.

😊 PC durability helps companies significantly cut maintenance costs.

Why does PC perform stably in complex applications?

PC’s weather resistance and fatigue strength allow it to maintain structural integrity under heavy loads and demanding conditions. This stability reduces losses caused by material failure in automotive, electronics, and industrial sectors. Its long-term performance generates lasting business value for enterprises.

- Adaptation to harsh environments: PC withstands temperature and humidity challenges.

- Reduced downtime: Stability enables continuous equipment operation.

- Extended product life cycle: Longer usability broadens applications.

- Strengthened brand reliability: Stable performance builds competitiveness.

💡 PC stability minimizes loss costs in complex applications.

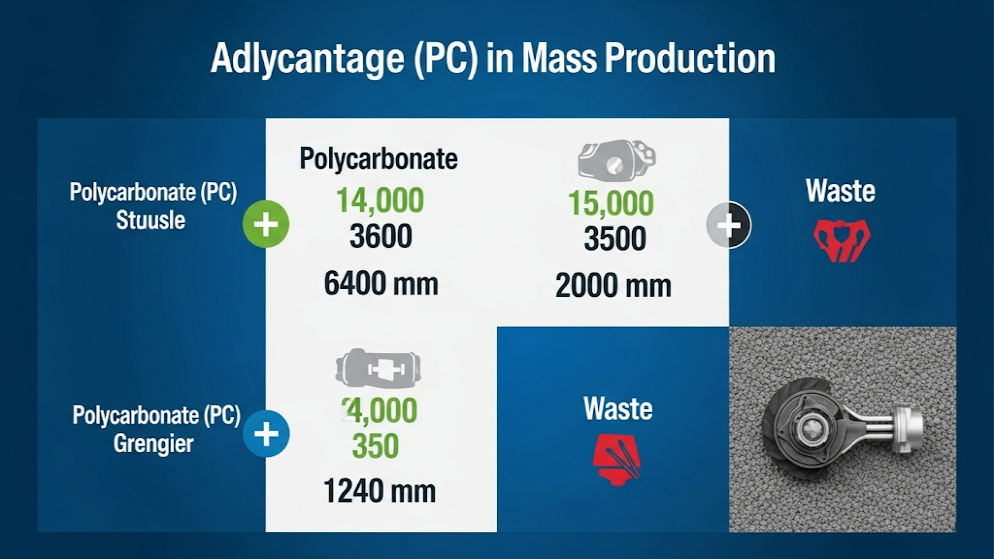

How does PC durability create advantages in mass production?

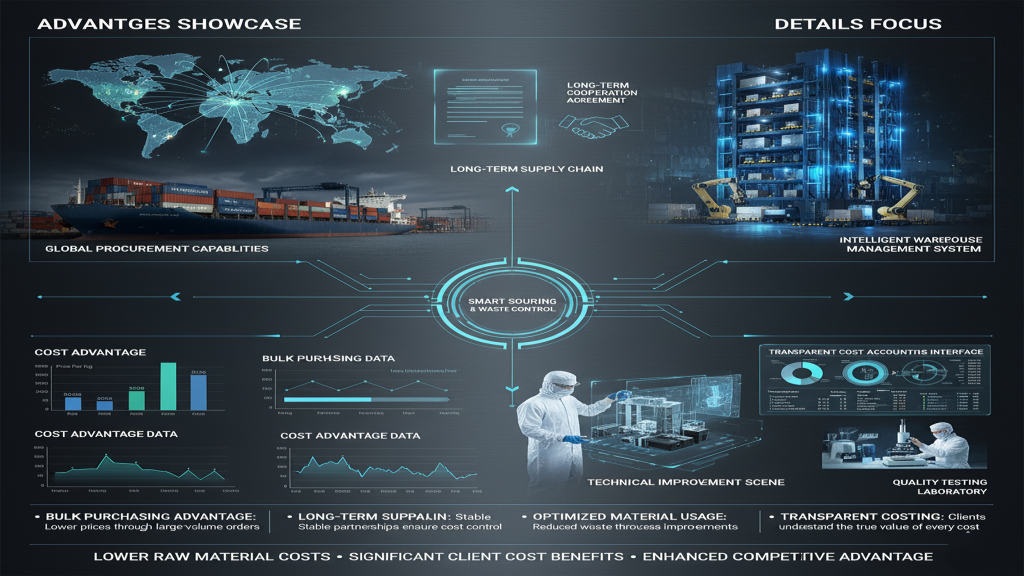

PC shows high consistency and excellent dimensional stability in injection molding, making it ideal for mass production. This consistency reduces scrap rates and shortens production cycles, helping companies save on large-scale manufacturing costs. In a competitive market, such efficiency becomes a decisive edge.

- Reduced scrap rates: High stability leads to higher yields.

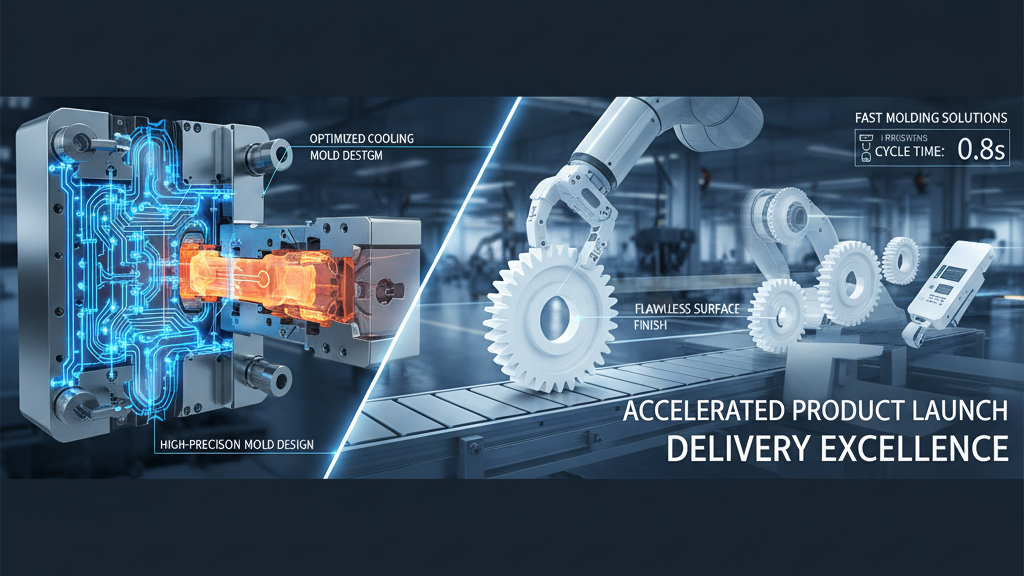

- Shortened molding cycle: PC performs efficiently within molds.

- Lower material waste: Precision reduces unnecessary consumption.

- Improved production efficiency: Mass production becomes more economical.

🚀 PC enables significant cost advantages in mass manufacturing.

Comparison of PC Durability and Cost Control

| Factor | PC Advantage | Regular Plastics | Cost Impact |

|---|---|---|---|

| Wear resistance | High | Medium | Low upkeep |

| Service life | Long | Short | Saves cost |

| Molding stability | Excellent | Average | Less scrap |

| Environmental adaptability | Strong | Weak | Less downtime |

Extension

In practice, PC not only helps companies reduce maintenance costs, but also enhances design flexibility and competitiveness. By cutting production waste and improving efficiency, PC becomes the optimal material choice for balancing performance and cost. With growing demand for high-performance solutions, PC will expand its applications further.

1.Boost market competitiveness: PC improves product cost-effectiveness.

2.Enable design freedom: High performance broadens innovation options.

3.Lower long-term risks: Reduced after-sales and quality issues.

4.Support sustainable manufacturing: Durability reduces resource waste.

Conclusion

PC durability is not just about performance advantages, but also about delivering holistic value across production and application stages. It translates reliability into measurable cost savings, providing long-term benefits for enterprises. Choosing PC for injection molding is a strategic move that balances profitability and market positioning.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!