Introduction

Melt Flow Index (MFI) is a key parameter that measures the flowability of plastics under specific temperature and pressure, directly influencing molding behavior. Choosing the right MFI not only affects product appearance but also impacts production efficiency and cost control.Proper MFI selection enhances product consistency and production stability.

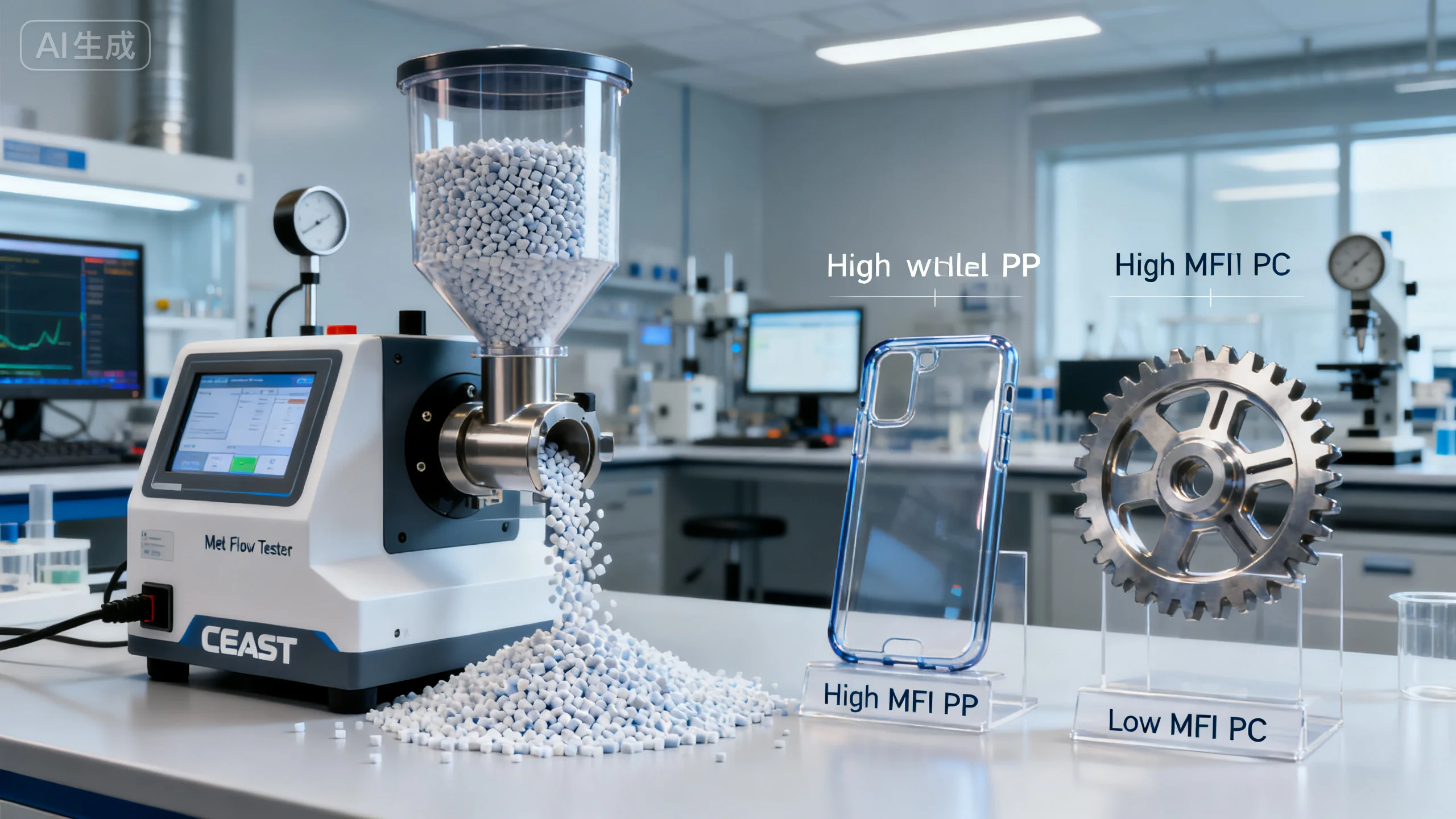

Different products require different MFIs: high MFI materials are suitable for thin-wall parts, while low MFI materials perform better in complex structures. By focusing on MFI during the development stage, companies can secure greater advantages in mass production.Matching MFI with product design requirements is the foundation for ensuring quality.

How Does MFI Affect Molding Efficiency?

The higher the MFI, the better the flowability, which reduces filling pressure during molding and improves efficiency for thin-wall products. Low MFI materials demand higher pressure and longer cycles.Selecting the right MFI range significantly impacts production speed and energy consumption.

- Process Matching: Aligning MFI with mold design improves efficiency.

- Energy Optimization: Proper MFI reduces machine energy usage.

- Dimensional Accuracy: Balanced MFI avoids short shots.

- Cycle Time: Correct MFI selection improves throughput.

😊 MFI is closely tied to efficiency, directly shaping cycle time and energy cost.

What Role Does MFI Play in Product Performance?

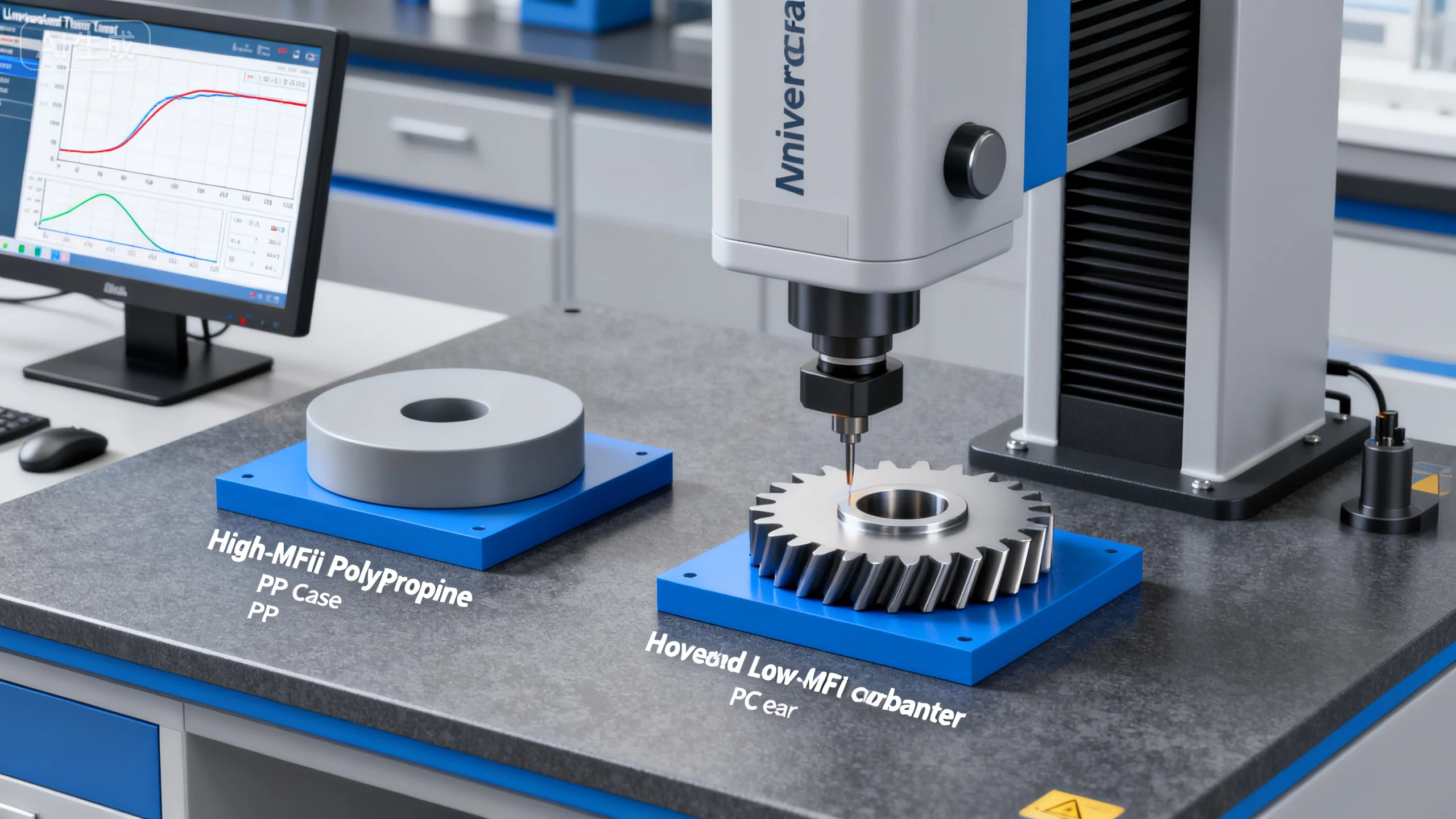

MFI affects not only processing but also the final properties of products. High MFI materials offer good flowability but may sacrifice strength, while low MFI materials provide higher strength but pose filling challenges.Balancing MFI between flowability and performance is critical.

- Mechanical Strength: Low MFI resins usually offer better impact resistance.

- Surface Finish: High MFI materials yield smoother product surfaces.

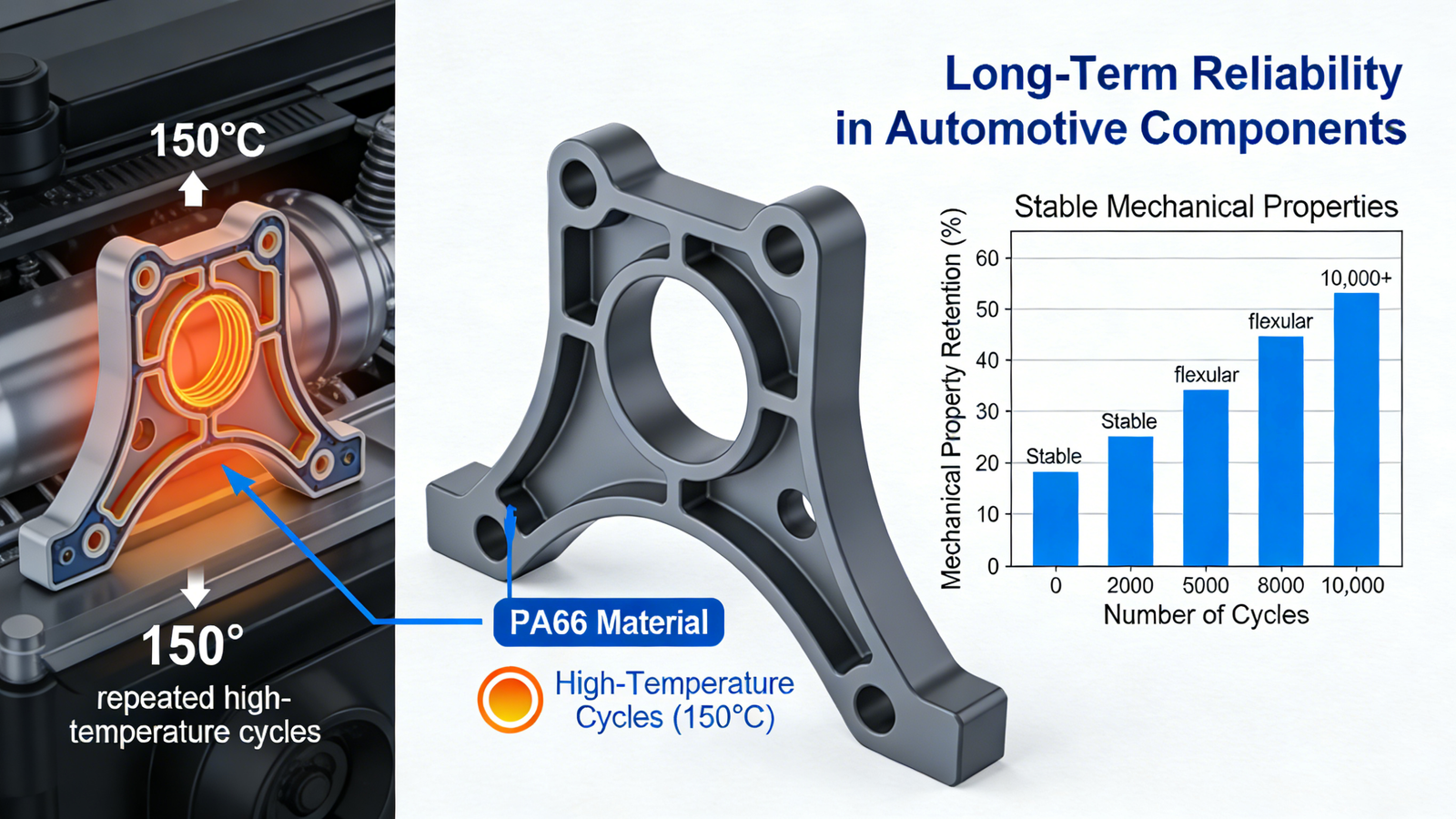

- Long-Term Stability: Proper MFI ensures durability in end-use.

- Flexibility Adjustment: MFI can help fine-tune material flexibility.

🔍 MFI differences directly influence product strength and surface quality.

How Does MFI Impact Mold Design and Process Setup?

Different MFIs demand adjustments in mold gate, runner, and cooling system design. High MFI allows smaller gates, while low MFI requires optimized flow channels to avoid short shots.Matching mold design with MFI is the key to stable processing.

- Runner Design: Different MFIs require tailored runner sizes.

- Cooling Performance: MFI influences shrinkage and cooling times.

- Gate Layout: Optimized layouts prevent weld lines.

- Process Flexibility: Correct MFI improves mold adaptability.

⚙️ MFI determines mold design strategy and process parameter choices.

MFI Adaptability Across Different Materials

| MFI Range | Processing Difficulty | Efficiency | Strength | Applications |

|---|---|---|---|---|

| Low MFI | High | Medium | High | Structural parts |

| Medium MFI | Medium | High | Medium | General parts |

| High MFI | Low | High | Medium-Low | Thin-wall parts |

| Ultra High MFI | Very Low | Very High | Low | Disposable items |

Leveraging MFI differences is the first step to developing efficient products. contact us for tailored solutions.

Expanding Applications with MFI

MFI is not just a lab parameter—it reflects how materials behave in real-world applications. By selecting the right MFI, companies can achieve wider process adaptability and market reach.MFI selection is the key to unlocking broader product opportunities.

1.Efficiency Gains: Optimize MFI to accelerate production.

2.Quality Assurance: Matching MFI reduces defect risks.

3.Innovation Space: Expands product application scope.

4.Market Competitiveness: Proper MFI creates business advantages.

Conclusion

MFI is a critical factor in injection molding, shaping efficiency, product properties, and mold design. Companies should align MFI with product requirements to achieve the best outcomes.MFI not only affects efficiency but also strengthens competitiveness in the market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!