Introduction

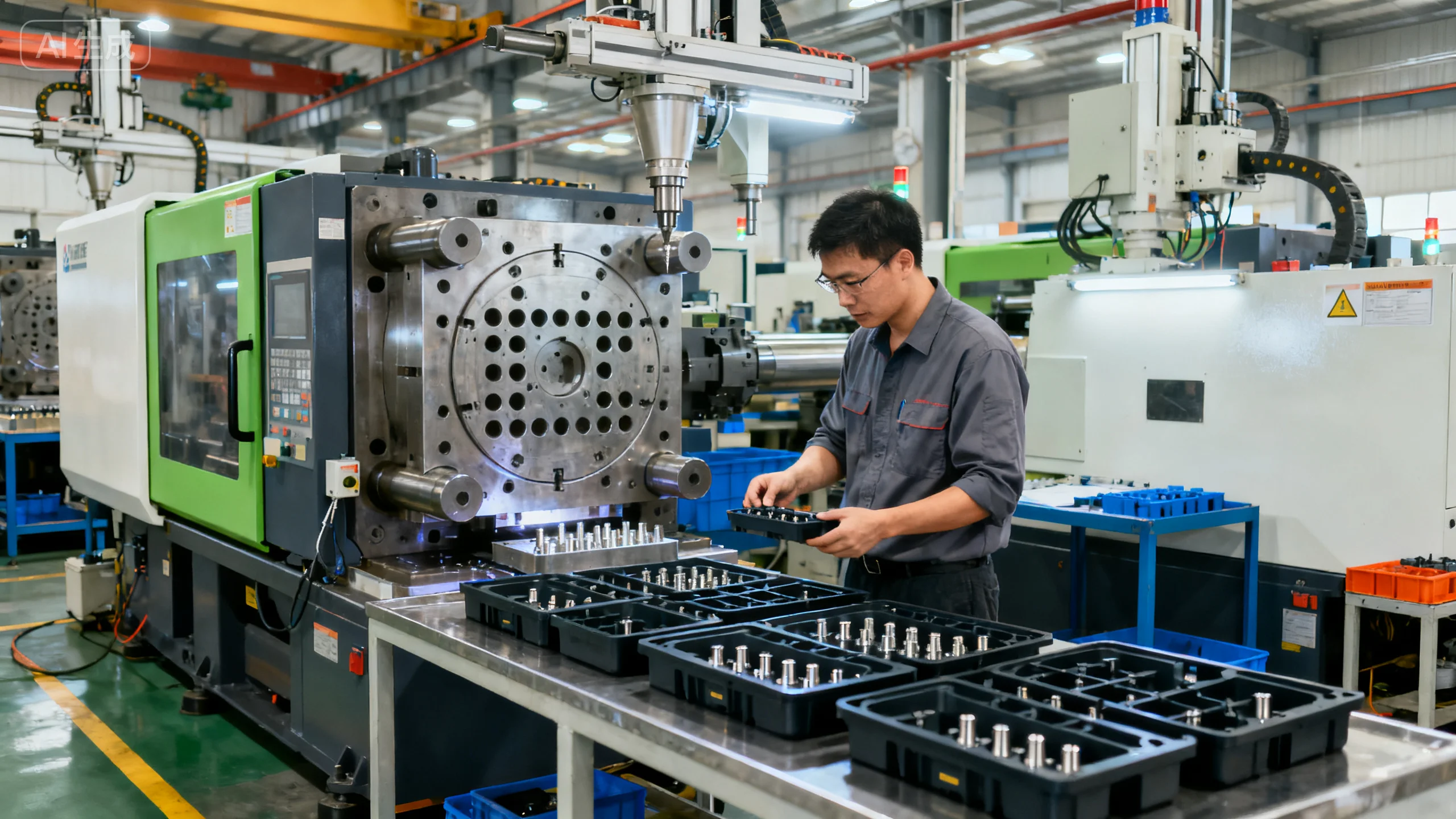

Co-injection molding enables the fusion of multiple materials in a single molding process, allowing different resins to bond seamlessly within one mold. This method significantly improves part strength and visual uniformity, making it ideal for automotive, electronics, and medical industries. It allows designers to create multifunctional, high-value products in one integrated step.

In composite structure development, co-injection molding not only optimizes assembly efficiency but also reduces the need for adhesives or fasteners. It helps manufacturers ensure structural integrity while lowering production costs. Thus, co-injection molding has become a key technology for achieving lightweight, high-performance composite structures.

How does co-injection molding fuse different materials?

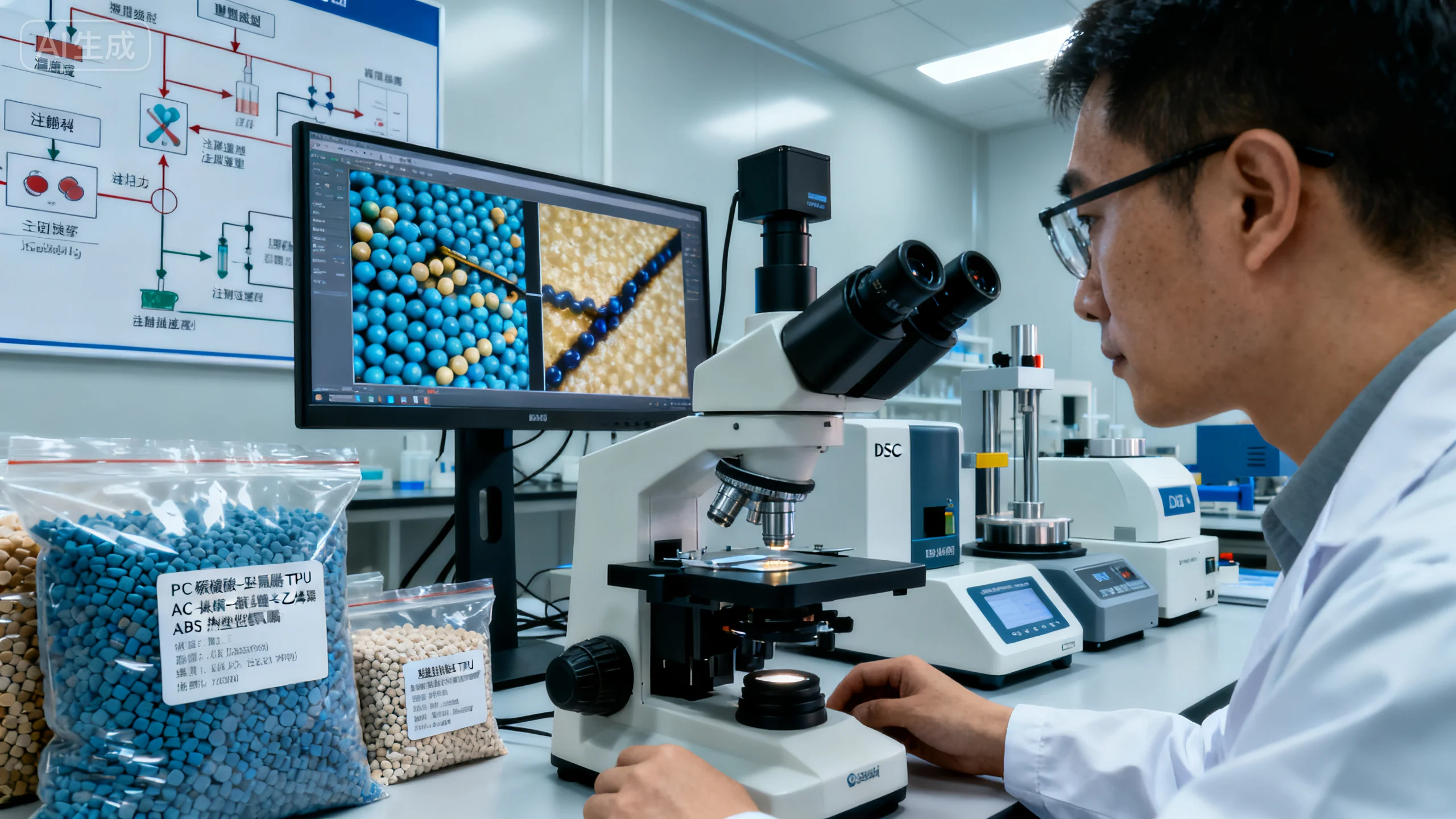

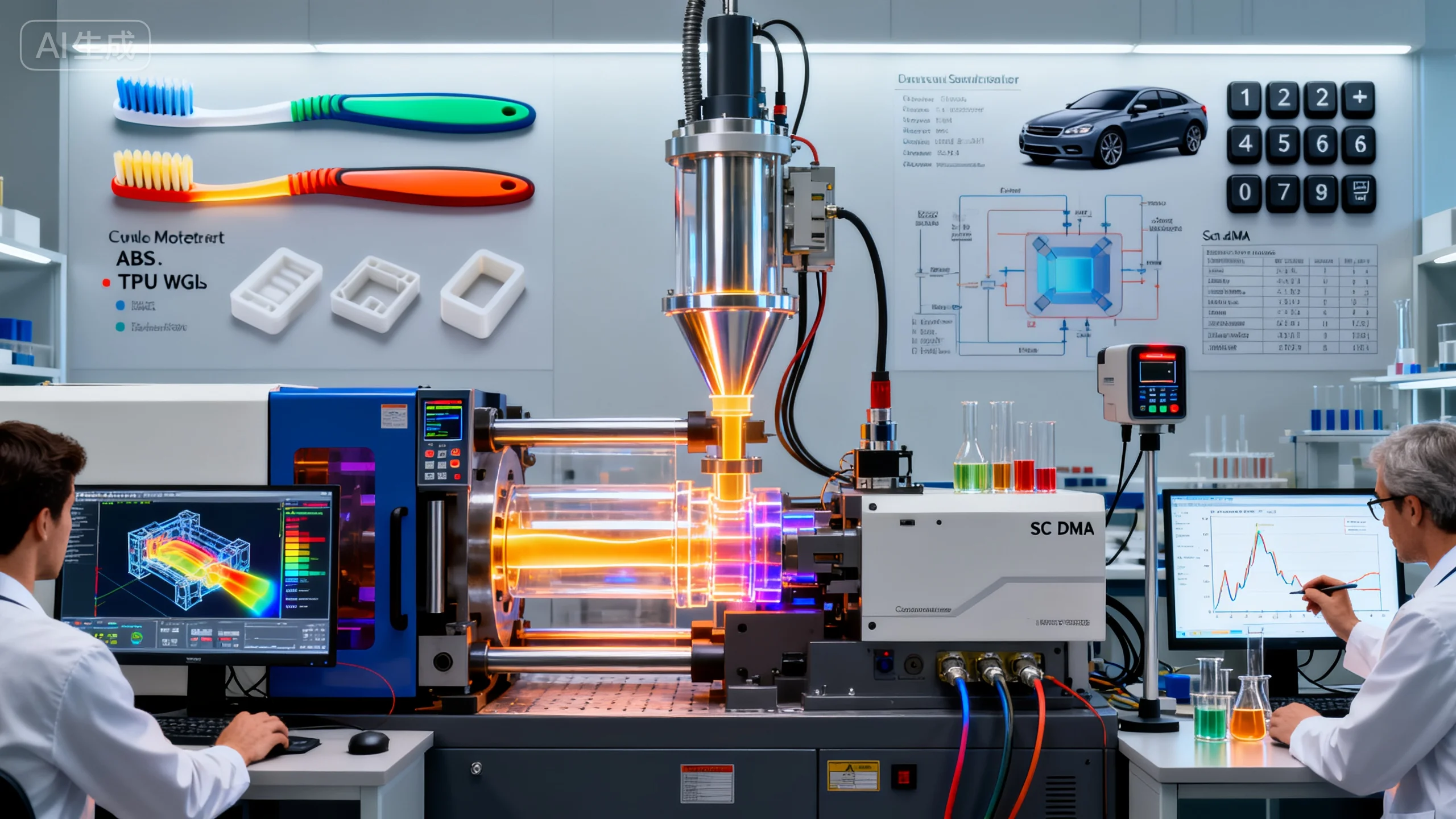

Co-injection molding uses dual-injection machines or multi-cavity molds to control resin flow and adhesion under specific temperature and pressure conditions. The core factors—interface compatibility, temperature coordination, and flow management—define both the strength and appearance of the final product. Precise interface control is the key to stable fusion.

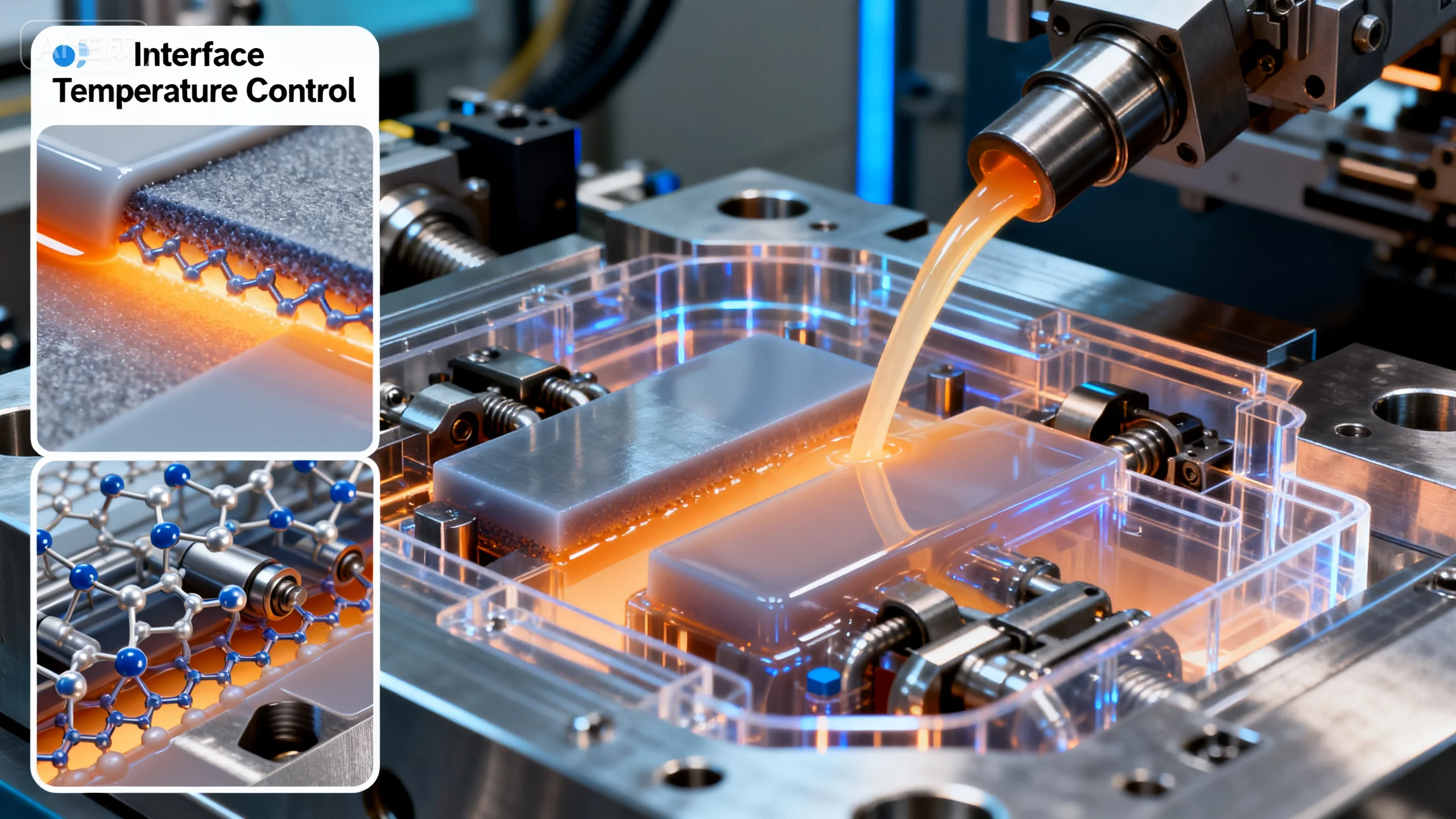

- Interface temperature control: A controlled temperature gradient ensures molecular interlocking between materials.

- Mold design optimization: Proper gate and flow channel placement prevents delamination and bubbles.

- Material compatibility testing: Experimental pairing determines the best resin combinations.

- Process synchronization: Matching pressure and cooling rates maintains a stable interface.

😊 The essence of co-injection molding lies in synergy between materials and process control.

How is composite structural strength ensured?

The strength of a composite structure depends on interface bonding, flow orientation, and uniform material distribution. By optimizing overmold thickness and injection sequence, manufacturers can significantly enhance part integrity and durability. The interface strength determines the overall performance of the molded composite.

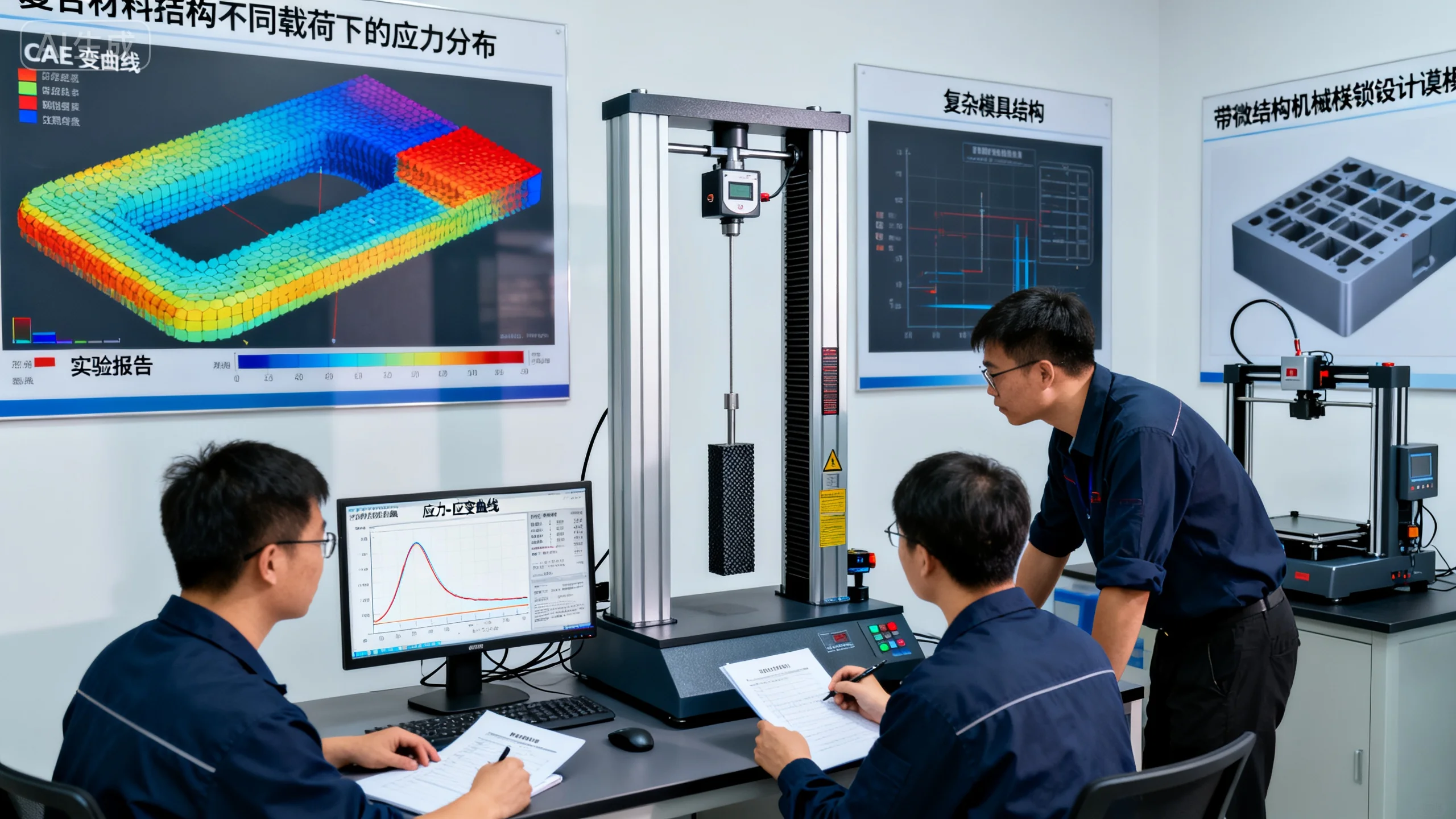

- Flow pressure distribution: Simulation analysis optimizes flow direction and minimizes internal stress.

- Mechanical interlock design: Microstructures added to the mold enhance surface grip.

- Temperature differential control: Precise thermal management prevents weak bonding.

- Stress optimization: CAE analysis identifies ideal layer thickness and ratios.

🔧 The strength of co-injection composites lies in balancing interface science and molding precision.

How to prevent delamination or bubbles in co-injection molding?

Delamination and bubbles typically result from poor compatibility or insufficient venting. By controlling melt temperature differentials and optimizing venting paths, such defects can be minimized. Stable melt flow and complete interface fusion ensure surface quality and internal stability.

- Mold venting design: Proper vent locations prevent trapped air.

- Melt temperature control: Maintaining similar viscosities ensures balanced fusion.

- Pressure compensation: Secondary packing during overmolding prevents voids.

- Material drying treatment: Pre-drying eliminates moisture-related bubbles.

💡 Stable co-injection molding depends on mastering flow, temperature, and venting control.

Performance Comparison of Co-Injection Composites

| Feature | Single Injection | Co-Injection Composite | Bonded Assembly | Secondary Assembly |

|---|---|---|---|---|

| Structural Strength | Medium | High | Medium | Low |

| Surface Uniformity | Good | Excellent | Fair | Poor |

| Cost Efficiency | Moderate | High | Low | Low |

| Production Cycle | Medium | Short | Long | Long |

Co-injection molding achieves multi-material fusion in one cycle—delivering strength and beauty in one. Learn more contact us.

Expanding Applications of Co-Injection Technology

Beyond structural components, co-injection molding is expanding into optical, tactile, and conductive applications. Through advanced formulations and precision mold control, manufacturers can produce anti-slip, wear-resistant, or conductive products. This versatility gives co-injection molding a strong competitive edge in product design.

1.Automotive industry: Integrates soft-hard combinations for panels and seals.

2.Electronics: Embeds conductive and tactile layers in buttons and housings.

3.Medical devices: Improves ergonomics and chemical resistance through dual-material molding.

4.Consumer products: Creates high-end designs combining functionality and aesthetics.

Conclusion

Co-injection molding unites structure, function, and aesthetics through a single-step process—providing efficient solutions for composite designs. It reduces assembly costs, enhances strength, and expands design freedom. By integrating materials and processes, co-injection molding stands at the forefront of advanced manufacturing.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!