Introduction

Modular design has become synonymous with efficiency and flexibility in plastic manufacturing. For ABS injection parts, modular connectivity not only optimizes assembly structures but also enhances expandability for multifunctional products. This design approach enables manufacturers to save substantial time and cost during part replacement or upgrade.

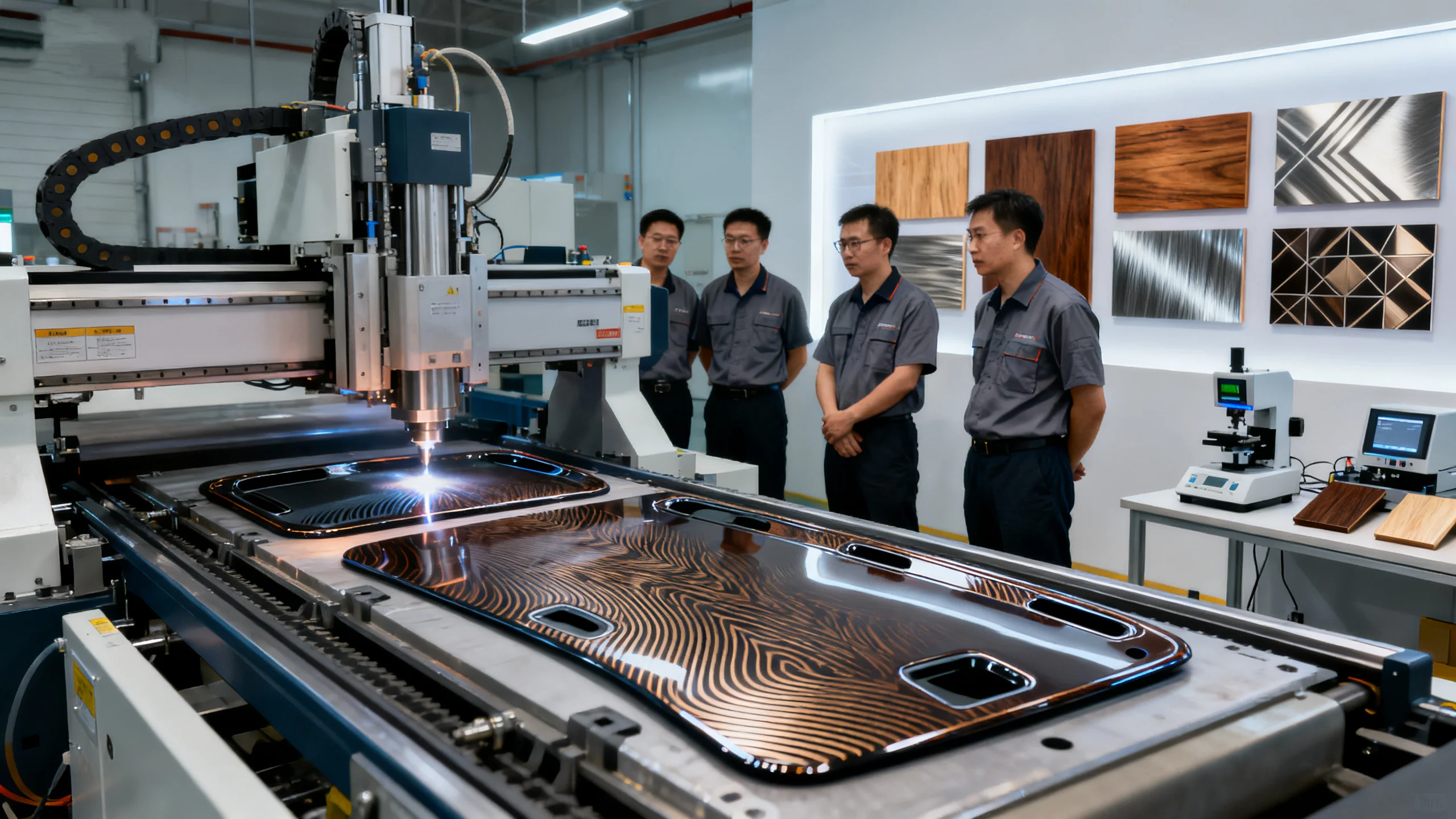

In industries such as consumer electronics, home appliances, and automotive interiors, ABS stands out for its processability and dimensional stability, making it the ideal choice for modular injection solutions. Through precise structural planning and advanced mold control, ABS parts can achieve accurate interlocking connections at every interface.

How Can Structural Design Enable Modular Connectivity?

Achieving modular connectivity depends on smart interface layout and reliable locking mechanisms. ABS material, with its high rigidity and excellent flowability, enables complex designs such as clips, slots, and sliding joints. Accurate structural design is the foundation for seamless modular assembly.

- Snap-Fit Design: Allows tool-free, quick assembly between modules.

- Slot Alignment: Ensures precise positioning and prevents assembly offset.

- Threaded or Sliding Joints: Facilitates disassembly and easy replacement.

- Precision Tolerance Control: Maintains interface accuracy through mold optimization.

💡 The essence of modular structure design lies in achieving precise interlocking and efficient assembly.

How Do ABS Material Properties Support Modular Injection Molding?

ABS offers outstanding toughness, impact resistance, and dimensional stability—making it ideal for modular applications. Its excellent melt flow supports complex interface structures, while its thermal stability maintains assembly precision. Material performance directly determines the reliability and durability of modular systems.

- Enhanced Toughness: Prevents stress cracking during assembly.

- Thermal Deformation Control: Maintains fit accuracy by minimizing shrinkage.

- Surface Formability: Suitable for coating, plating, or insert decoration.

- Fatigue Resistance: Ensures long-term connection stability.

⚙️ The balanced properties of ABS make modular injection engineering highly practical.

How Can Assembly Precision Be Ensured in Modular Production?

Assembly accuracy in modular systems directly affects functionality and aesthetics. Through mold tolerance optimization, controlled injection parameters, and advanced inspection systems, manufacturers can ensure consistent fit across modules. High-precision molding is the key to scalable modular production.

- Tolerance Optimization: Controls dimensional precision and minimizes offset.

- High-Precision Mold Fabrication: Guarantees smooth, perfectly aligned interfaces.

- Automated Inspection Systems: Continuously monitors gaps and alignment.

- Temperature & Humidity Control: Prevents thermal expansion from affecting fit.

🔧 Assembly precision defines the long-term reliability of modular injection parts.

Comparison Table of Modular Connection Types

| Connection Type | Key Features | Ease of Assembly | Cost Efficiency | Common Applications |

|---|---|---|---|---|

| Snap-Fit | Tool-free quick connection | ★★★★★ | ★★★ | Consumer electronics |

| Threaded | Reusable and adjustable | ★★★ | ★★★★ | Industrial components |

| Sliding Rail | Smooth and guided fit | ★★★★ | ★★★ | Home appliances |

| Insert Assembly | High strength & conductivity | ★★★ | ★★★★★ | Automotive modules |

Looking to improve precision and connection strength? Reach out to us via contact us for tailored modular injection solutions!

Modular Injection Application Expansion

Modular injection molding extends beyond single products to interchangeable structures and multifunctional assemblies. By optimizing interfaces and assembly strategies, ABS modules enable flexibility and rapid customization throughout a product’s lifecycle. This empowers manufacturers to iterate faster and maintain competitive differentiation.

1.Consumer Electronics Modularity: Smartphone or display housing systems.

2.Home Appliance Modularity: Replaceable front shells and internal supports.

3.Automotive Interior Modularity: Quick-switch between different configurations.

4.Industrial Equipment Modularity: Simplified maintenance and scalable setups.

Conclusion

ABS modular injection molding delivers flexibility, precision, and scalability to modern manufacturing. Through the synergy of material selection, structural design, and mold engineering, companies can achieve cost-efficient, high-quality modular assemblies. Modular connectivity not only improves manufacturing agility but also sets the stage for future smart production.

For expert assistance in implementing modular ABS injection solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!