Introduction

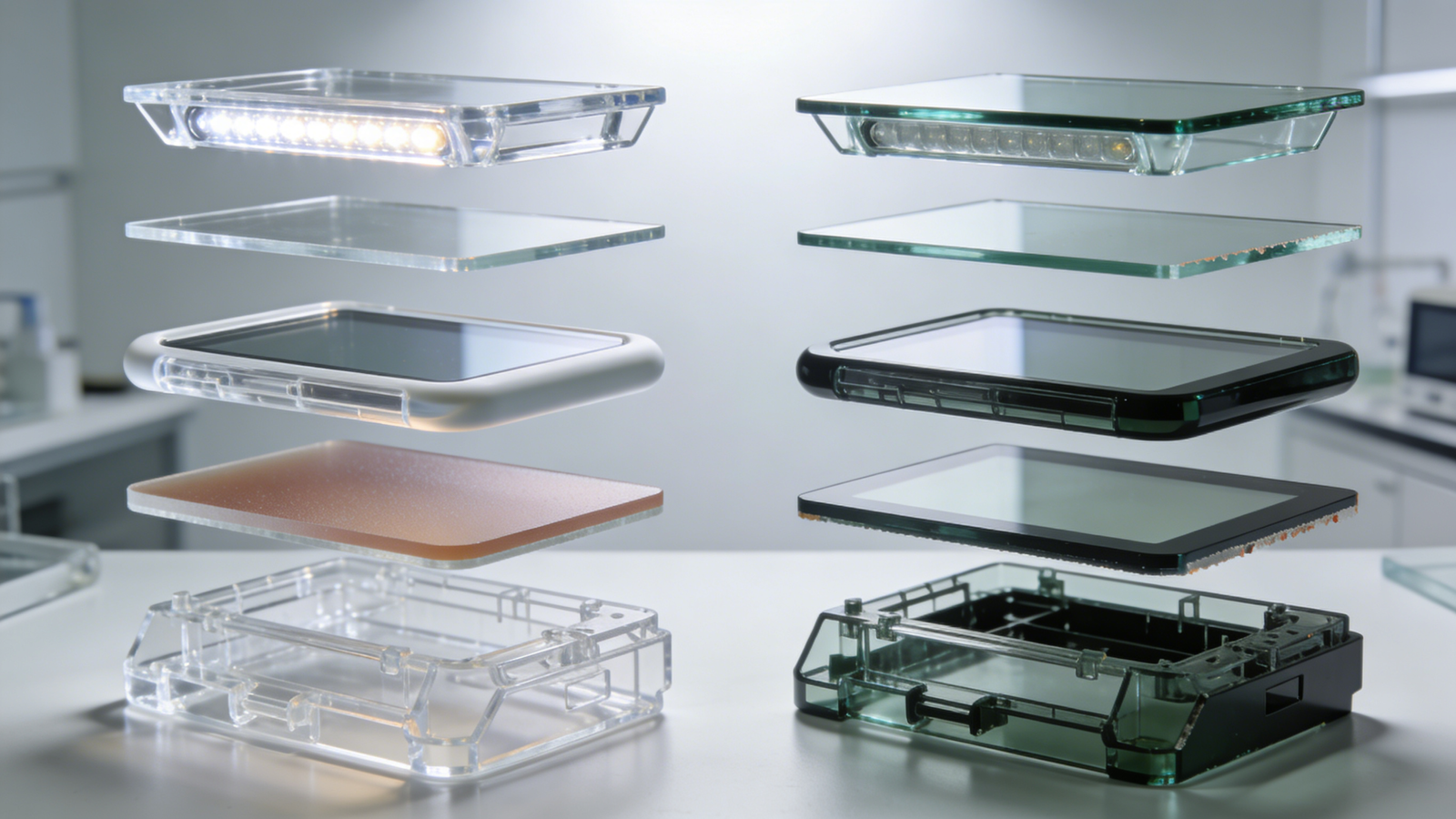

Plastic brittleness does not only come from the material itself but is also deeply affected by molding process conditions. Even slight deviations in temperature, pressure, and cooling rate can directly determine the stability of product performance. With scientific process settings, brittleness issues can be significantly reduced.

Process optimization not only prevents cracking but also enhances the overall mechanical toughness of plastics. Different plastic types require tailored molding strategies to ensure both performance and appearance. A well-designed process is the core guarantee for the reliability of plastic parts.

How can temperature control reduce plastic brittleness?

Temperature control is one of the most critical factors affecting plastic toughness. Proper melt and mold temperature settings can promote molecular chain activity and reduce stress concentration. The optimization of temperature settings determines the final mechanical performance of plastic parts.

- Mold temperature optimization: Balanced mold temperature reduces internal stress.

- Stable melt temperature: Ensures flowability and prevents chain breakage.

- Uniform cooling: Avoids shrinkage differences that lead to cracks.

- Proper holding pressure: Keeps molecular arrangement stable and reduces brittleness.

😊 Temperature stability is the first step in minimizing brittleness.

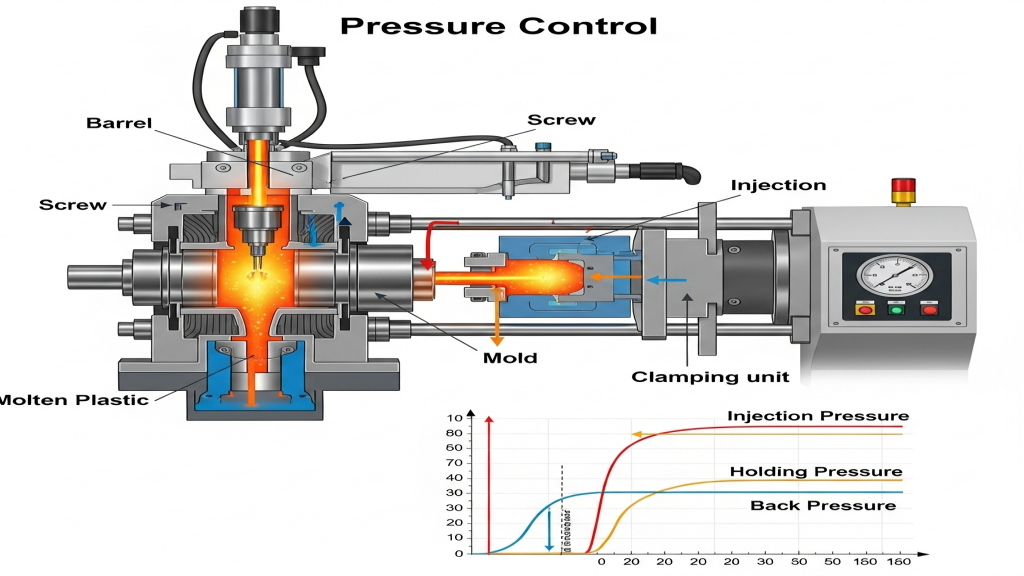

How do pressure parameters improve the toughness of plastics?

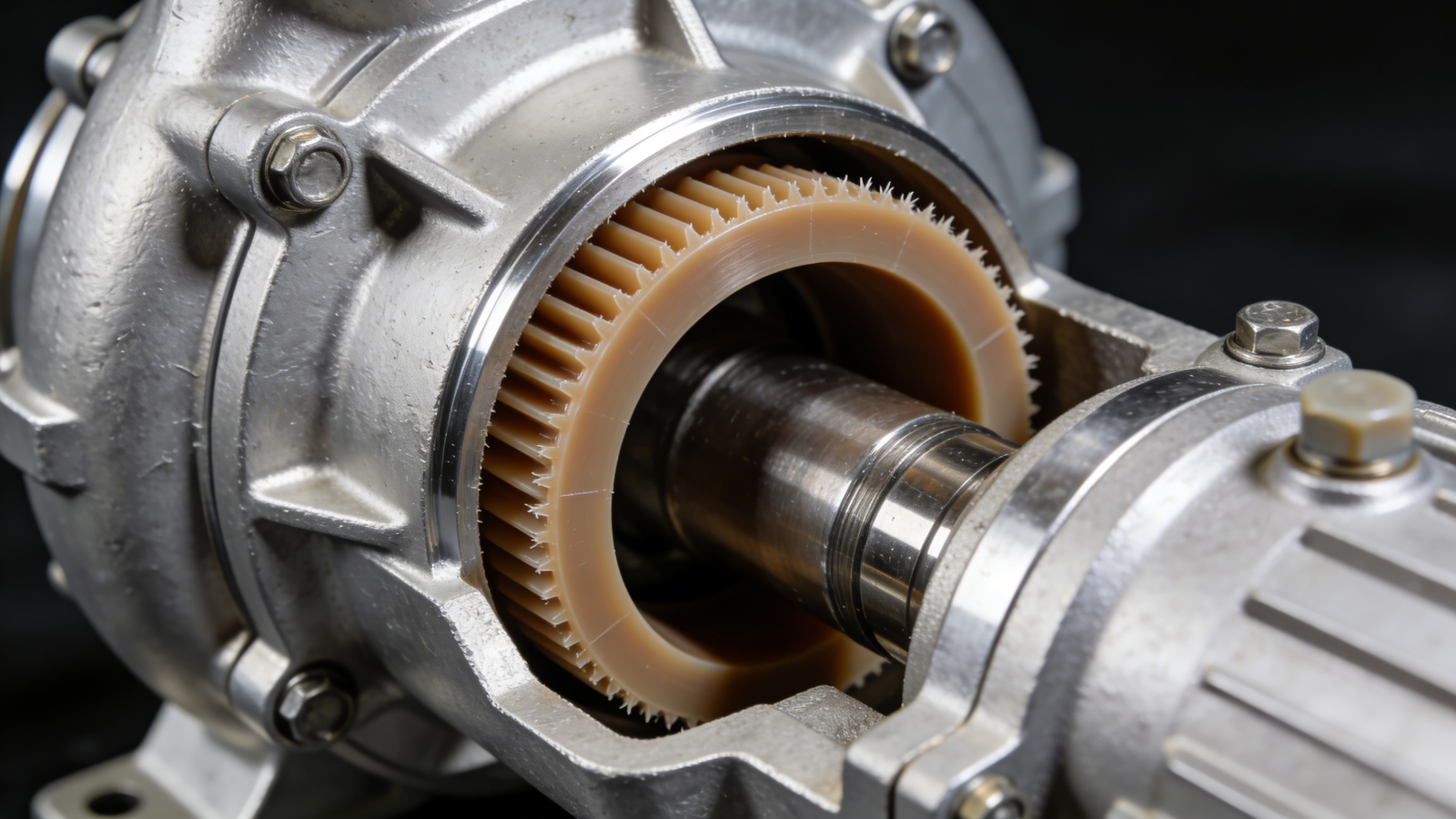

The molding pressure directly determines the orientation and bonding of molecular chains. By optimizing injection and holding pressures, the density and impact resistance of plastics can be improved. Pressure settings are an important balance point in solving plastic brittleness.

- Injection speed adjustment: Prevents over-orientation caused by rapid filling.

- Stable holding pressure: Increases density and reduces micro-voids.

- Good venting: Prevents gas entrapment that causes cracks.

- Multi-stage pressure control: Enables flexible and stable molding.

💡 Proper pressure management makes plastic parts tougher and more reliable.

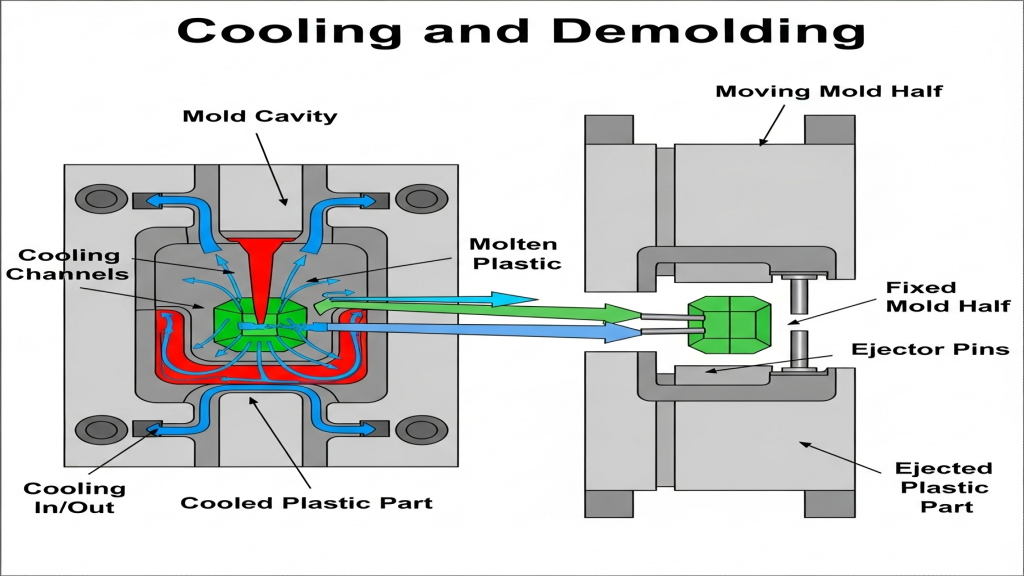

How do cooling and demolding affect plastic brittleness?

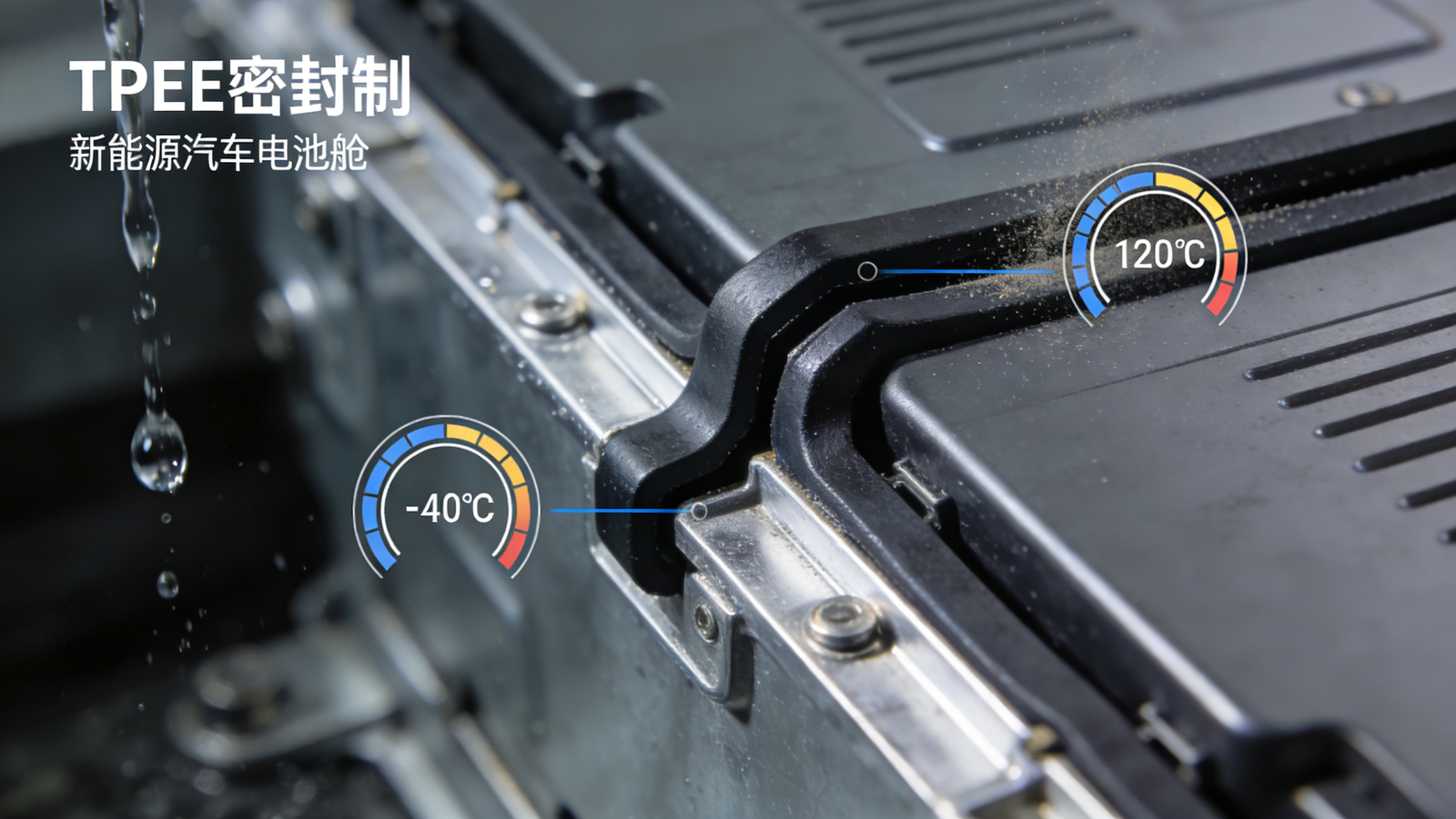

Cooling and demolding stages are often underestimated, yet they have a profound impact on toughness. Rapid cooling may cause internal stress accumulation, while poor demolding practices can lead to microcracks on the surface. Optimizing cooling and demolding effectively extends the service life of plastic parts.

- Cooling rate control: Prevents stress from sudden cooling.

- Zoned cooling design: Ensures uniform shrinkage across the part.

- Balanced demolding force: Reduces surface stress marks.

- Assisted demolding: Gas ejectors or slides protect fragile areas.

🚀 Scientific cooling and demolding are the final safeguards against brittleness.

Process Optimization vs. Brittleness Control

| Process Factor | Mechanism | Key Benefit | Risk Control |

|---|---|---|---|

| Temperature | Chain mobility | Toughness boost | Stress control |

| Pressure | Density effect | Crack reduction | Avoid overpressure |

| Cooling | Shrinkage balance | Crack prevention | Residual stress relief |

| Demolding | Stress release | Surface integrity | Damage prevention |

Process Extension

Process optimization is not just about solving brittleness but also about improving overall production efficiency. A well-coordinated process reduces defect rates, extends mold life, and maximizes material utilization. Full-process optimization brings higher competitiveness to the enterprise.

1.End-to-end monitoring: Digital tracking ensures stable parameters.

2.Digital simulation: CAE analysis supports design validation.

3.Team collaboration: Process, design, and production integration improves efficiency.

4.Continuous improvement: Test molding data supports ongoing refinement.

Conclusion

Plastic brittleness is not caused by a single factor but by the combined effects of temperature, pressure, cooling, and demolding. Scientific process optimization is the fundamental safeguard of plastic part reliability. With tailored adjustments based on material properties and production requirements, manufacturers can achieve both toughness and efficiency. Ultimately, this ensures product quality and helps enterprises gain an edge in the market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!