Heat-resistant PVC drainage pipes are becoming the preferred choice in building drainage systems due to their excellent temperature resistance and chemical stability. Formula optimization not only increases the heat deformation temperature but also extends the overall service life.Improved heat resistance is the key to product competitiveness.

By adjusting the types of plasticizers, stabilizers, and fillers used in PVC, high-efficiency mass production of heat-resistant drainage pipes via injection molding can be achieved. We are committed to providing solutions that offer both high temperature resistance and structural strength.Formula modification is the core solution to heat resistance needs.

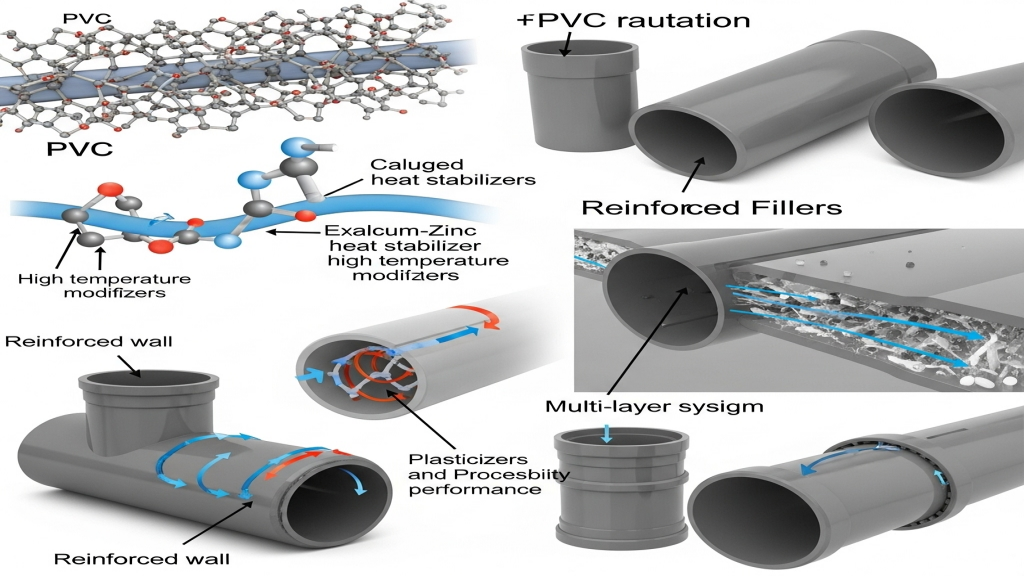

How Does a Special Formula Enhance PVC Heat Resistance?

Special formulations introduce heat stabilizer systems and high-temperature modifiers to endow PVC with excellent thermal properties and aging resistance. The selection of high molecular weight materials further improves the product’s pressure resistance and deformation tolerance.Adding a thermal stabilization system effectively extends product lifespan.

- Efficient Heat Stabilizers: Improve resistance to thermal aging.

- Reinforced Fillers: Enhance pipe stiffness using materials like glass fiber.

- Modifier Technologies: Optimize flow and processing window.

- Optimized Structural Ratios: Prevent stress from thermal expansion.

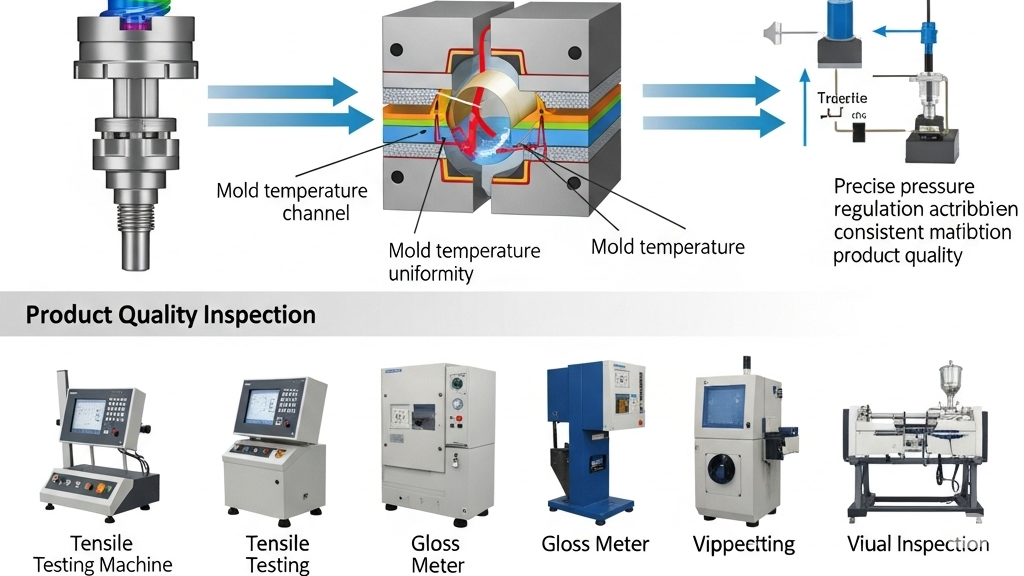

How to Ensure Thermal Stability in the Injection Process?

Precise control of temperature, screw speed, and back pressure is required during molding to prevent PVC thermal degradation, which causes bubbles and discoloration. Mold temperature control also contributes to the product’s thermal performance. Accurate processing parameters are essential for consistent quality.

- Screw Temperature Zoning: Ensures uniform material plastification.

- Mold Temperature Controllers: Optimize the cooling curve.

- Back Pressure Optimization: Stabilizes melt density and reduces defects.

- Proper Holding Time: Minimizes internal stress accumulation.

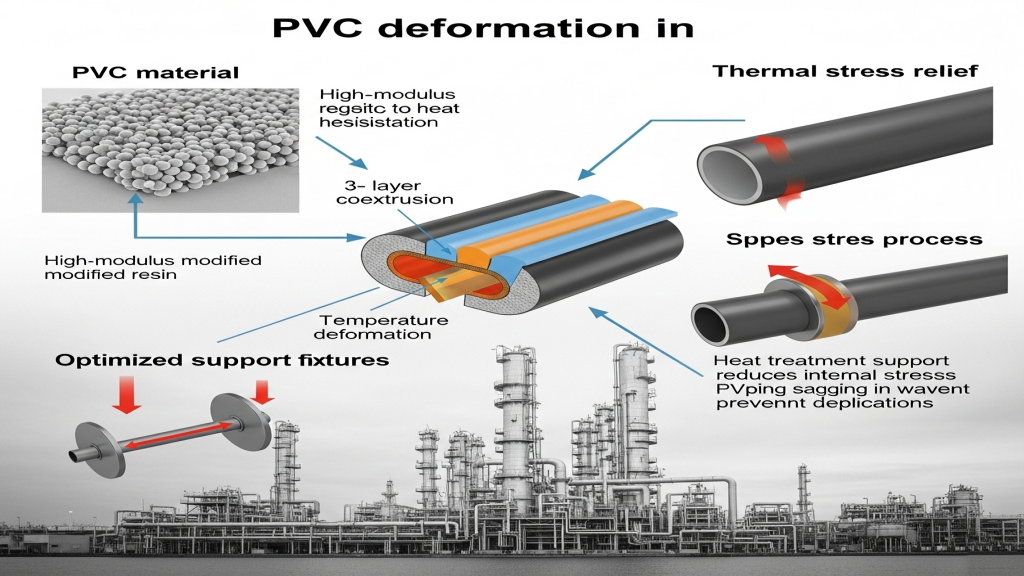

How to Prevent PVC Deformation in High-Temperature Applications?

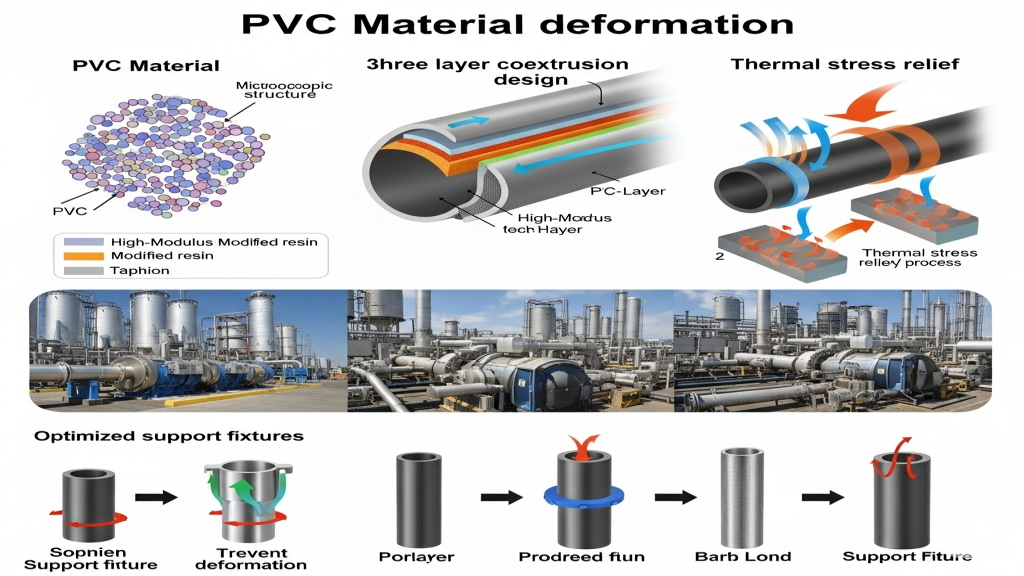

Under long-term high temperatures, standard PVC tends to soften and deform. Special formulations can significantly improve resistance to deformation through elevated heat deflection temperatures and structural reinforcement.Resistance to high-temperature deformation defines suitability for hot water systems.

- High-Modulus Modified Resin: Increases pipe rigidity and pressure tolerance.

- Three-Layer Coextrusion Design: Middle for heat resistance, outer for protection.

- Thermal Stress Relief: Mitigates fatigue from thermal cycling.

- Optimized Support Fixtures: Reduce sagging due to weight and heat.

Modified vs. Standard PVC

| Item | Standard PVC | Heat-Resistant PVC | Hot Water PVC | Rigid PVC Drain |

|---|---|---|---|---|

| Heat Deflection Temp | 65℃ | 85℃ | 95℃ | 80℃ |

| Thermal Aging Life | 1000h | 2500h | 3000h | 1800h |

| Injection Temp Range | Narrow | Wide | Wide | Medium |

| Impact Resistance | Fair | Excellent | Excellent | Moderate |

How to Position Heat-Resistant Pipes in Premium Markets?

Through a combination of engineered design and formula optimization, we provide stable drainage solutions for high-temperature environments. Compared to traditional materials, modified PVC offers better performance and optimized cost.The commercial value of heat-resistant formulas is expanding PVC’s use cases.

1.Lower Tech Barrier: Enables small manufacturers to enter high-end markets.

2.Increased Market Demand: Hot water and construction industries are booming.

3.New Application Scenarios: Includes floor heating and hotel wastewater systems.

4.Optimized Raw Sourcing: Use of domestic additives lowers costs.

Conclusion

The success of heat-resistant PVC pipes lies not only in innovative formulations but also in refined injection molding techniques. Through dual advancements in materials and processing, we provide high-performance and cost-effective piping solutions. As demand for thermal stability continues to grow, modified PVC will be a core material for future piping innovations.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!