Polycarbonate (PC) injection parts are widely used for precision housings and optical components due to their transparency and strength. Without strict quality control during production, variations in dimensions and surface finish can compromise function and appearance.Only a full-process quality control system can ensure consistent performance for every batch of PC parts.

From raw material inspection to molding control, quality management must be implemented at every step. Ignoring small details can result in costly rework and customer returns.Building a standardized and digital dual-control system is key to avoiding batch inconsistencies.

How do we ensure consistency of PC injection parts at the source?

Source control is the first line of defense for quality. From material certification to incoming inspection, each step determines the consistency of later molding.If raw material consistency is ignored, even the best molds and processes cannot correct upstream flaws.

- Material Selection Standardization: Set usage standards for polycarbonate grades.

- Batch Traceability System: Track material origins to avoid mixed lots.

- Moisture Management: Strict drying conditions prevent splay marks.

- Masterbatch Ratio Control: Maintain consistent color across batches.

How do we avoid process-induced differences during injection molding?

Process control during molding is critical to maintaining quality. Variations in mold temperature, injection speed, and back pressure can directly impact dimensions and finish.High-precision machines with closed-loop control ensure stability in mass production.

- Mold Temperature Monitoring: Ensure consistent temperatures for each shot.

- Standardized Injection Speed: Define ideal flow rates for each product type.

- Back Pressure Control: Prevent melt density variation.

- Cycle Time Management: Ensure cooling and packing consistency for every mold.

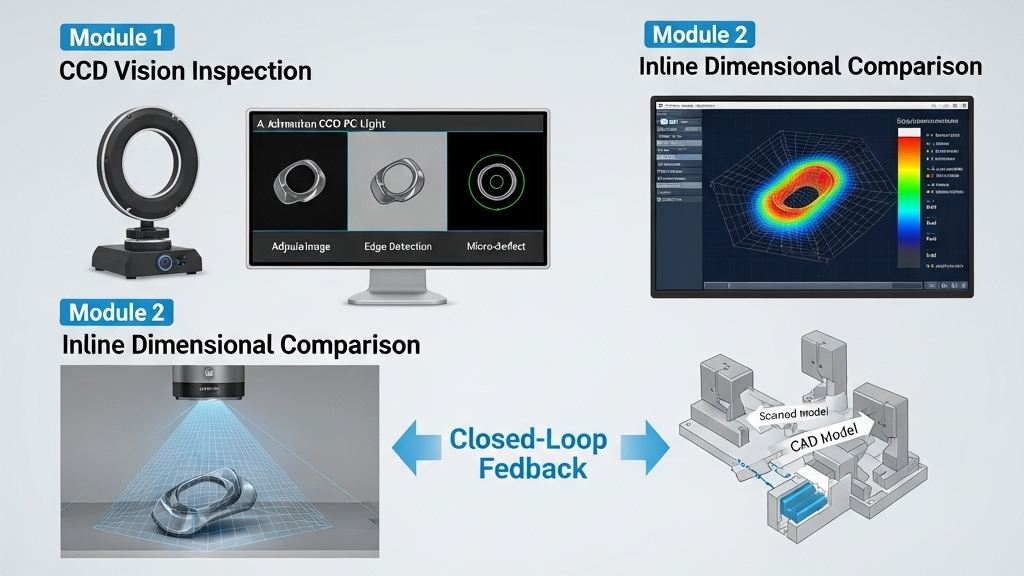

How do we detect and fix micro-differences in post-inspection?

Post-molding inspection isn’t just a routine—it's a critical checkpoint for variance control. Manual inspection alone is insufficient; digital measurement and reference samples are required.Advanced imaging and automated measurement technologies significantly improve PC part inspection accuracy.

- CCD Vision Inspection: High-magnification defect detection.

- Inline Dimensional Comparison: Compare against CAD models for deviation.

- Functional Tolerance Testing: Evaluate structural part fit and function.

- First Article & Sampling System: Use golden samples and periodic checks.

Quality Control Dimensions

| Control Phase | Standardization | Automation | Variance Control | Cost | Coverage | Risk Alert | Customer Returns |

|---|---|---|---|---|---|---|---|

| Material Mgmt | High | Medium | Low | Med | Broad | Medium | Low |

| Molding Control | High | High | Very Low | High | Broad | High | Very Low |

| Inspection | Medium | High | Medium | High | Broad | High | Low |

| Packaging & Ship | Medium | Medium | Medium | Med | Full | Medium | Medium |

How do we maintain stable quality through system construction?

A robust quality system must link process, equipment, personnel, and data together. Rather than optimizing one link, companies should build coordinated controls across standardization, execution, and monitoring.Only system-level quality control can deliver consistency amid complex part structures and batch fluctuations.

1.Process Standardization: SOPs for every step eliminate human error.

2.Smart Equipment: Automated feedback and alarms correct deviations.

3.Data Visualization: Quality dashboards display real-time key metrics.

4.Skilled Workforce: Trained staff ensures process integrity.

Conclusion

Avoiding quality variation in PC injection parts requires a full-chain control system, not isolated measures.Strong quality comes from standard procedures, closed-loop data, and precise execution.In today’s precision molding environment, only a systematic quality management approach can ensure part consistency and customer satisfaction.

For expert assistance in implementing precision PC injection solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!