Introduction

Agricultural machinery operates for long periods in environments filled with dust, mud, moisture, and frequent washing, where enclosure failure can directly lead to electronic malfunction or system shutdown. An injection molded housing is not simply a protective shell, but a functional interface that must isolate sensitive components from harsh external conditions.

What truly determines IP65 reliability is not a single specification, but whether the enclosure is designed around real operating conditions. At Xiamen Ruicheng, IP protection is considered at the earliest design stage to ensure long-term stability throughout the product lifecycle.

How can injection molded housings maintain long-term sealing in dusty agricultural environments?

Agricultural dust consists of fine particles that continuously impact enclosure joints during operation, and sealing solutions relying solely on assembly pressure often fail under vibration. By integrating labyrinth-style sealing structures directly into the molding design and combining them with integrated gasket grooves, dust ingress paths are significantly extended and weakened. Structural sealing provides far greater durability than solutions that rely purely on adhesives. In addition, designs are validated against IP65 protection requirements to ensure consistent performance even after repeated assembly and maintenance.

Structural dust protection: Multi-step and folded pathways reduce direct particle intrusion.

Material compatibility: Dimensionally stable engineering plastics minimize gaps caused by thermal expansion.

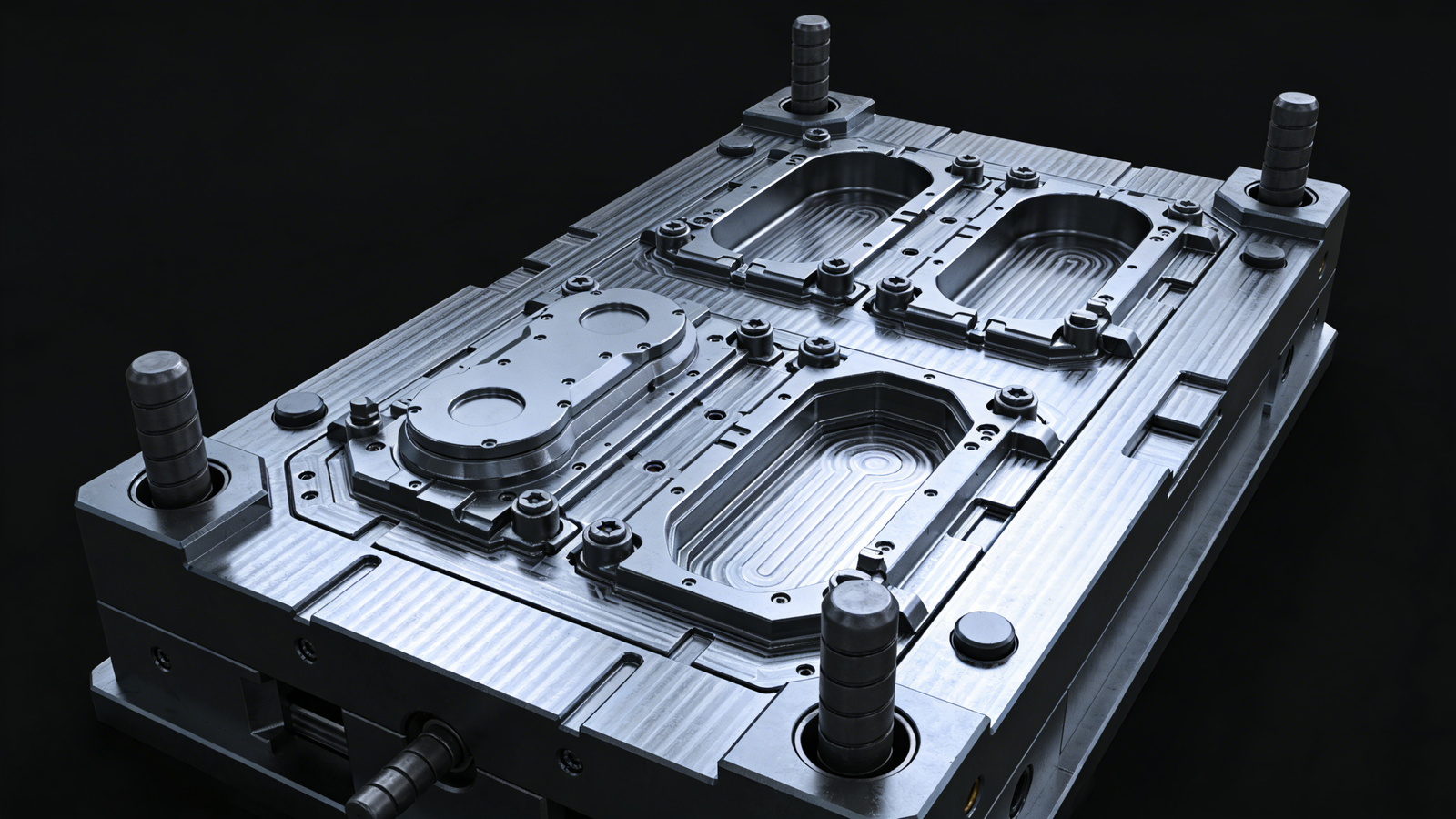

Process coordination: Mold precision and venting are optimized to avoid micro-cracks from residual stress.

Assembly validation: Vibration simulations are conducted early to confirm long-term reliability.

🙂 Controlling dust paths at the structural level is the first safeguard for agricultural enclosures.

How do injection molded housings resist high-pressure washing and water penetration?

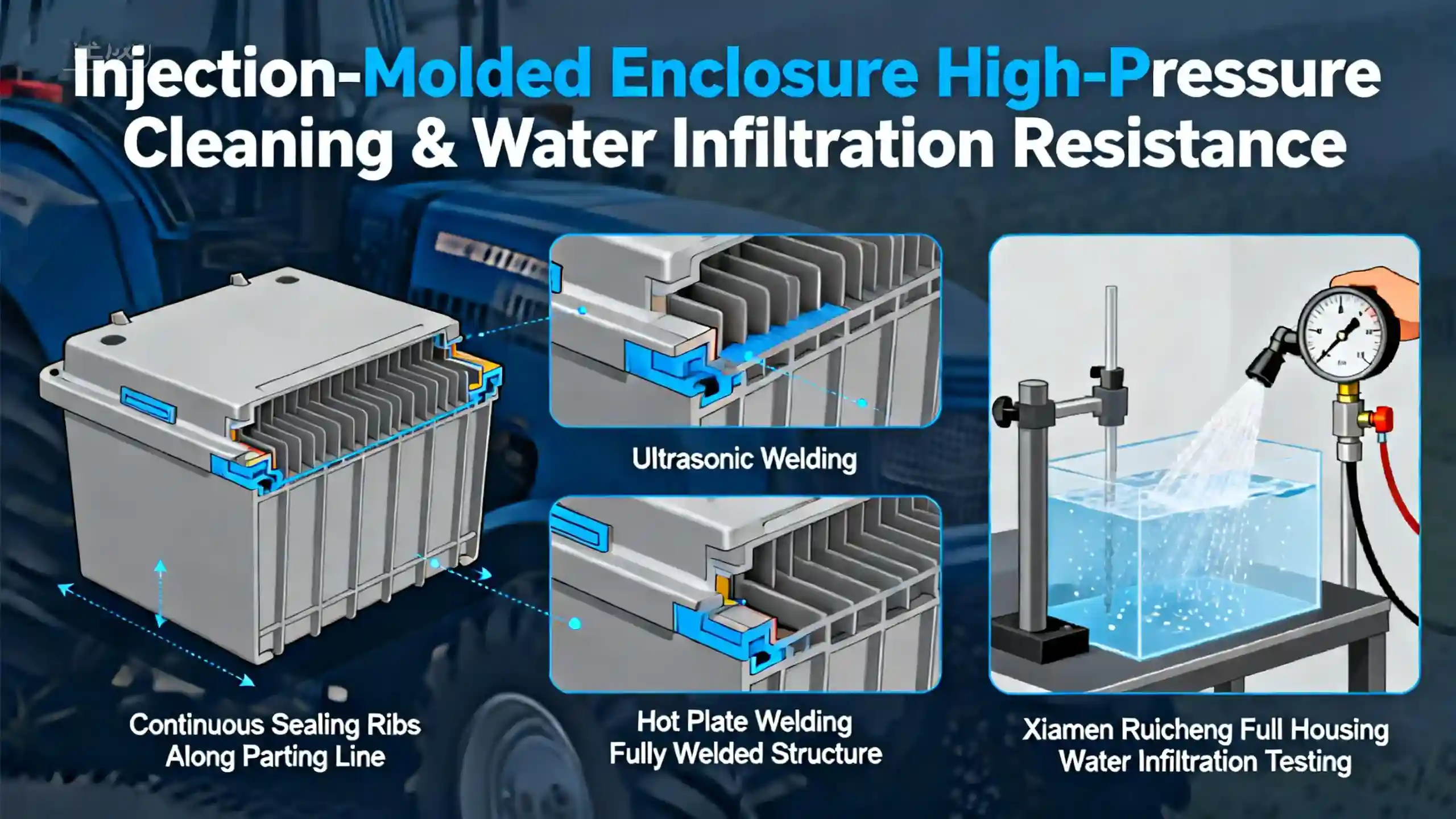

Agricultural equipment is often cleaned using high-pressure water jets, creating momentary pressures far exceeding natural rainfall. Continuous sealing ribs along parting lines, combined with ultrasonic welding or hot-plate welding, eliminate leakage risks associated with screw holes. One-piece welded structures remove dependence on manual assembly consistency for waterproof performance. At Xiamen Ruicheng, each welded housing undergoes full-shell ingress protection testing to verify real-world resistance.

Interface simplification: Reducing exposed openings lowers potential water entry points.

Welding design: Energy directors ensure uniform and continuous weld seams.

Drainage strategy: Controlled water guidance prevents long-term moisture accumulation.

Testing loop: Full housing tests replace partial inspections to reflect actual use risks.

💧 Effective waterproofing relies on design and process integration, not sealing alone.

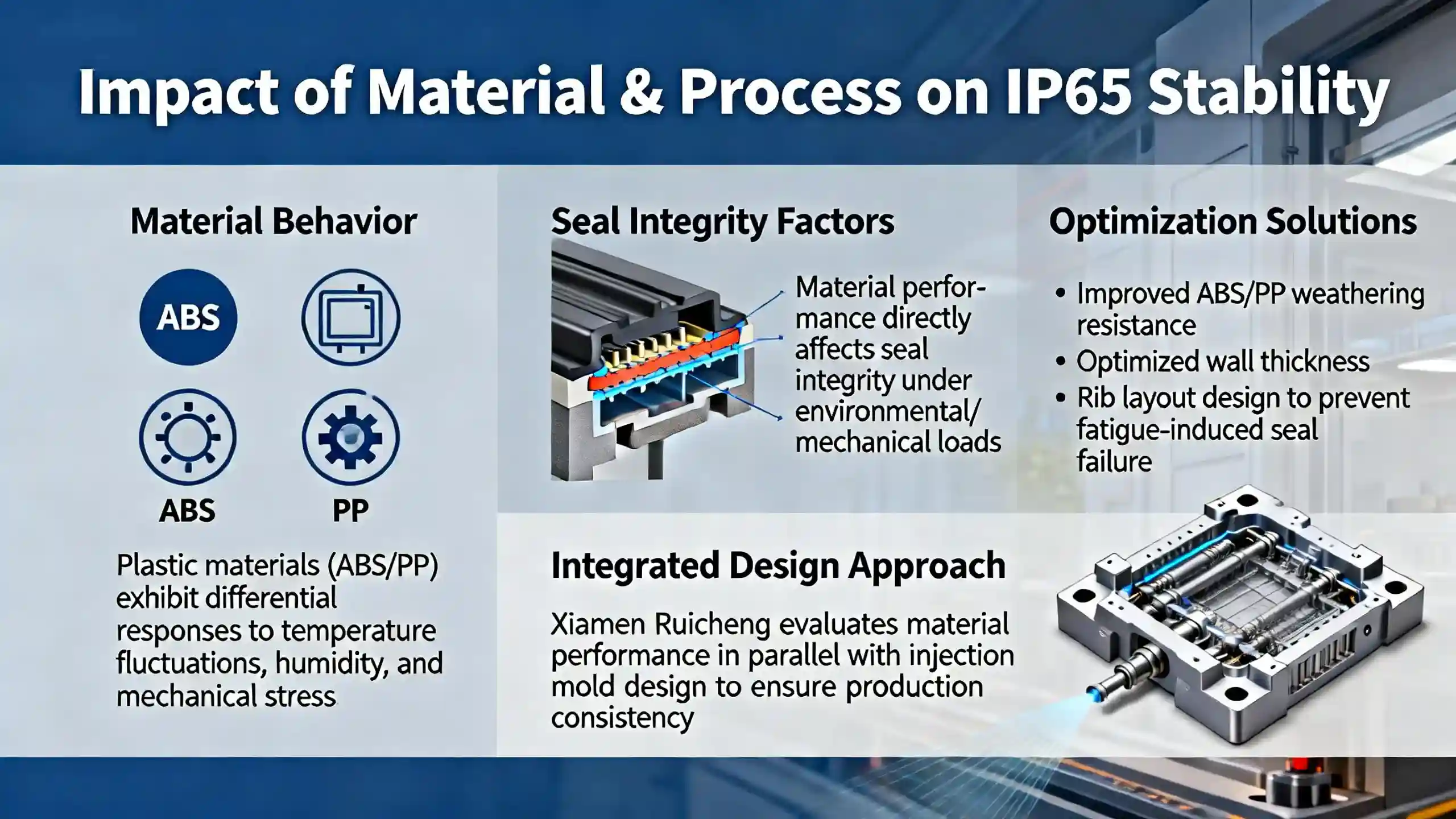

How do material and process choices affect IP65 stability?

Plastic materials behave differently under temperature fluctuation, humidity, and mechanical stress, directly impacting sealing integrity over time. Modified ABS or PP with enhanced aging resistance, combined with optimized wall thickness and rib layouts, helps prevent fatigue-related sealing failure. Material decisions must align with structure and process, rather than being made in isolation. Xiamen Ruicheng evaluates material performance in parallel with injection mold design to ensure production consistency.

Weather resistance: Long-term exposure effects are assessed during material selection.

Wall thickness control: Uniform sections minimize shrinkage-related sealing distortion.

Mold accuracy: Precision tooling reduces reliance on assembly compensation.

Production stability: Process windows are defined to ensure repeatable mass production.

🧩 IP65 is not a one-time test result, but a condition sustained by materials and processes.

Comparison of IP65 implementation paths for agricultural enclosures

| Solution Type | Screw-Based Sealing | Adhesive Sealing | Integrated Welding | Xiamen Ruicheng System Approach |

|---|---|---|---|---|

| Dust Resistance | Medium | Medium | High | High |

| Water Resistance | Assembly-dependent | Aging risk | High | High |

| Maintenance Cost | High | Medium | Low | Low |

| Long-Term Consistency | Unstable | Degrading | Stable | Stable |

Looking to determine which approach best fits your agricultural platform? Feel free to reach out directly: contact us

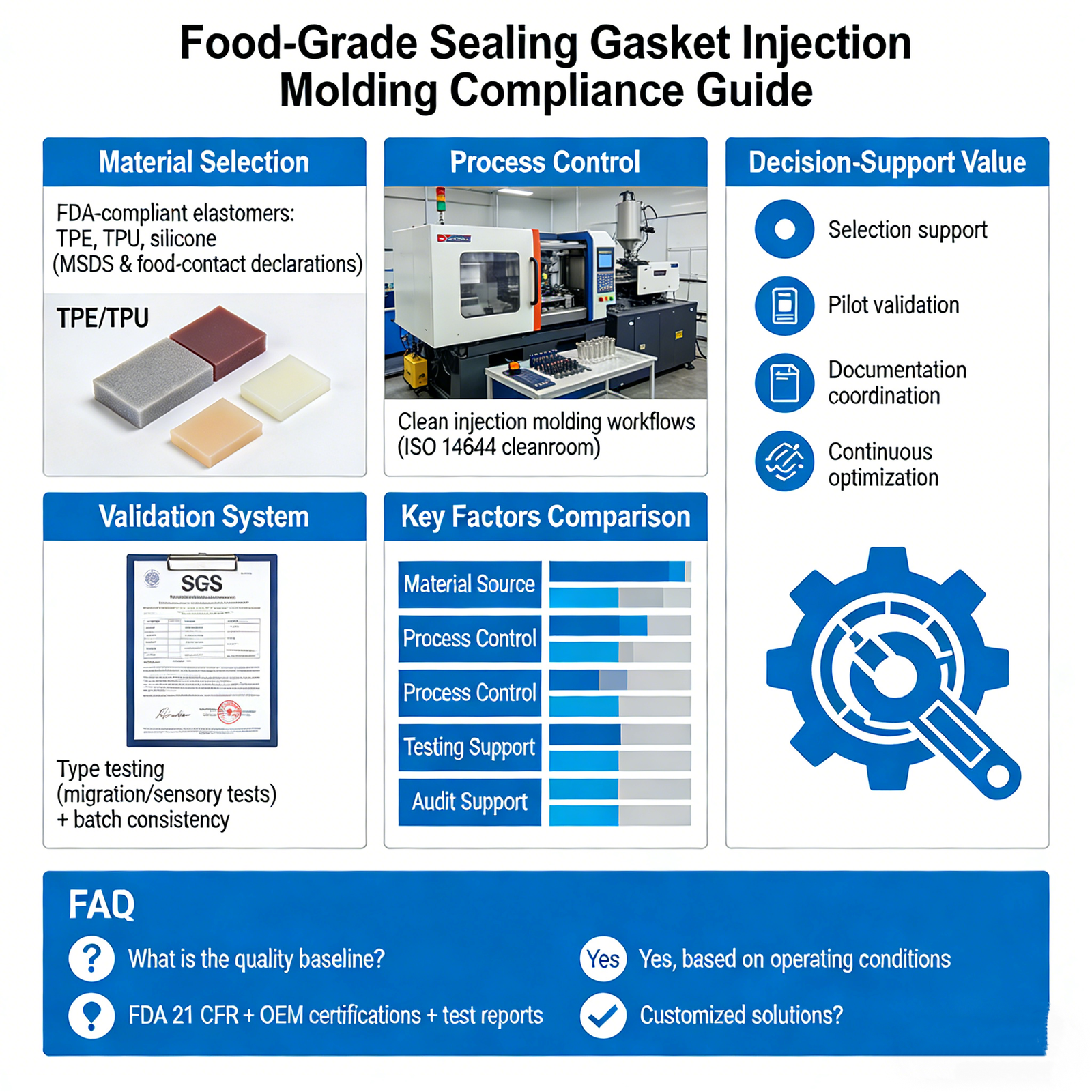

From concept to mass production: making IP protection work

Achieving IP65 for agricultural housings is not a one-time design task, but a system-level process spanning the entire product lifecycle. Xiamen Ruicheng integrates operating conditions, assembly methods, and production capacity into a unified decision framework. This continuity from concept to mass production is what ensures protection performance is truly delivered.

1.Operating condition first: Real usage environments are treated as design constraints.

2.Structure-driven design: Structural solutions are prioritized over auxiliary materials.

3.Process validation: Pilot runs include IP testing to reduce scale-up risks.

4.Continuous optimization: Designs are refined based on field feedback and data.

Frequently Asked Questions (FAQ)

Question 1: What is the core advantage of your IP65 agricultural housing solution?

Answer: Our strength lies in a system-level approach combining structure, material, and process control, supported by defined IP65 testing standards to ensure long-term reliability for procurement partners.

Question 2: What information is required to start a customized IP65 enclosure project?

Answer: Basic drawings, installation details, operating environment descriptions, and estimated volumes enable us to quickly evaluate feasibility and provide a structured proposal within an agreed timeframe.

Question 3: How do order volume and delivery timelines differ between trial and mass production?

Answer: Small-batch trials support low minimum quantities for validation, while mass production benefits from stabilized lead times and reserved capacity during peak seasons.

Question 4: How are post-delivery protection issues handled?

Answer: Clear evaluation criteria and response procedures are in place, allowing rapid root-cause analysis and corrective actions, including tooling or process adjustments when necessary.

Question 5: Can housings be customized for special agricultural operating conditions?

Answer: Yes, structures and materials can be adapted for extreme temperature variation, vibration, or cleaning frequency, with defined timelines and cost impacts communicated in advance.

Conclusion

Achieving IP65 dustproof and waterproof performance for agricultural injection molded housings requires a systematic response to real operating conditions rather than parameter stacking. Through structure-led design, material coordination, and closed-loop process control, protection performance can remain stable over long-term use. Choosing a manufacturing partner with proven system engineering capability is essential for true IP65 implementation. Xiamen Ruicheng remains committed to helping customers reduce risk and enhance equipment reliability.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!