Introduction

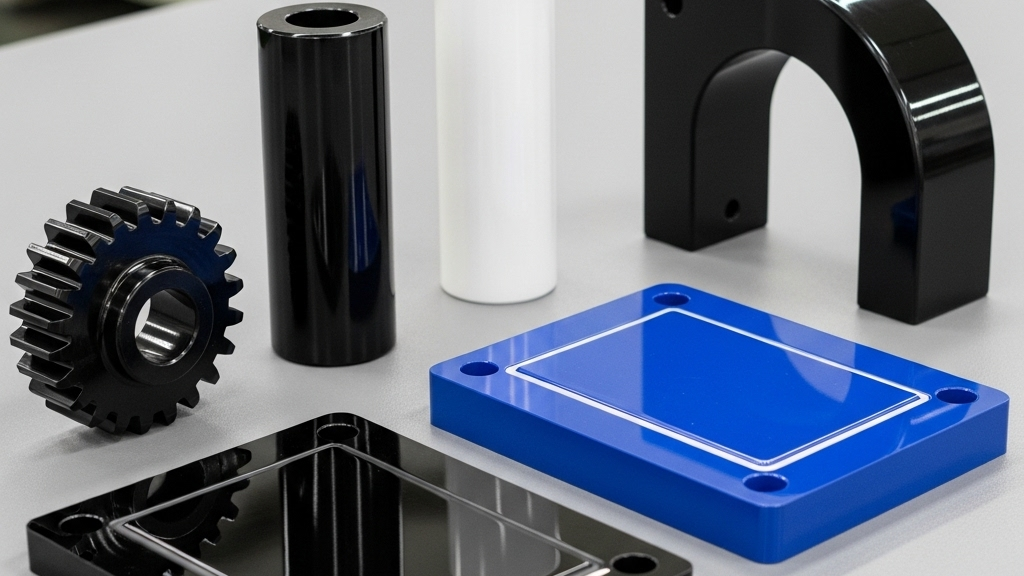

Delrin, as an engineering plastic, is widely used in parts that demand superior surface quality. With well-designed injection molding processes, the gloss of finished parts can be significantly improved, adding both visual and functional value. Gloss is not just an appearance indicator—it’s also the customer’s first impression of quality.

Improving gloss requires an integrated approach to mold design, process temperature control, and material properties. By managing these critical aspects throughout production, Delrin parts can achieve consistent and attractive surface finishes. Optimized molding processes make Delrin products stand out in premium markets.

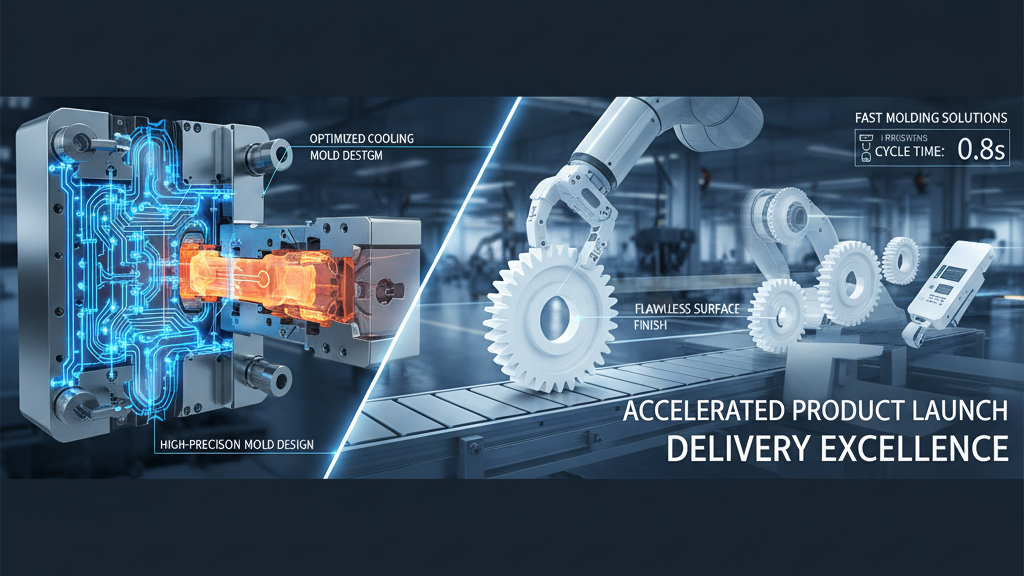

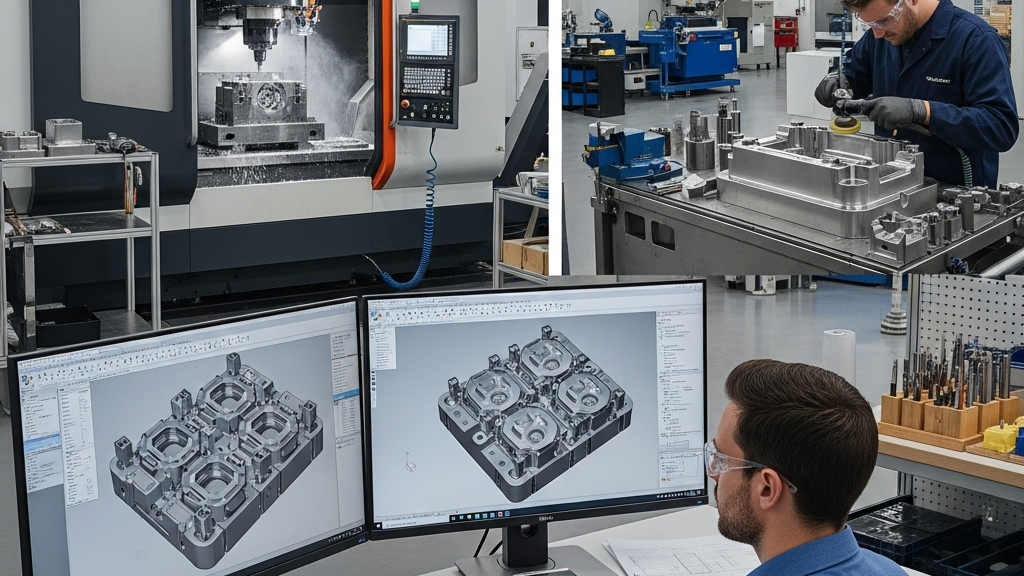

How Does Mold Design Influence Delrin Gloss?

Mold design is one of the primary factors that determines Delrin gloss. By refining gate placement, runner design, and mold surface finishing, defects can be minimized while surface smoothness improves. The surface treatment of the mold directly impacts the gloss level of parts.

- Precise Gate Layout: Guides flow to minimize weld lines.

- Efficient Cooling System: Ensures temperature balance and gloss consistency.

- Mold Surface Polishing: Enhances microstructure for better reflection.

- Runner System Optimization: Reduces pressure loss, improves filling quality.

✨ Mold design optimization maximizes the visual performance of Delrin parts.

How Does Temperature Control Improve Delrin Gloss?

Temperature management is a critical factor in achieving high-gloss surfaces. Proper adjustment of mold temperature, melt temperature, and cooling rates ensures surface flow quality and consistent gloss. Process temperature control is the key to achieving uniform gloss.

- Melt Temperature Adjustment: Improves flowability and surface finish.

- Mold Temperature Regulation: Stabilizes conditions, avoids gloss loss.

- Cooling Rate Control: Prevents stress concentration and surface dullness.

- Integrated Temperature Strategy: Secures consistency between production batches.

🌟 Temperature control strategies give Delrin parts more stable gloss effects.

How Can Process Parameters Optimize Delrin Gloss?

The proper setup of process parameters directly affects gloss stability. By adjusting injection speed, holding time, and cooling time, surface defects can be minimized and high-gloss finishes maintained. Process parameter optimization translates directly into improved visual quality.

- Injection Speed Tuning: Promotes better flow, reduces surface defects.

- Holding Time Optimization: Prevents shrinkage, maintains uniform surfaces.

- Cooling Cycle Control: Secures balanced temperatures and gloss.

- Integrated Process Window: Ensures stability in mass production.

💡 Smart parameter settings boost the visual appeal of Delrin products.

Key Comparisons for Delrin Gloss Enhancement

| Aspect | Mold Design | Temperature Control | Process Settings | Integrated Approach |

|---|---|---|---|---|

| Gloss Uniformity | High | High | Medium | High |

| Cost Input | Medium | High | Medium | High |

| Controllability | Medium | High | High | High |

| Application Range | Broad | Broad | Broad | Comprehensive |

Extended Applications

Enhancing Delrin gloss is not only a technical improvement but also a competitive advantage in the market. High-gloss products are widely adopted in automotive, consumer electronics, and home appliances. Gloss improvement helps companies stand out in customized, high-demand markets.

1.Automotive Components: Interior parts with a more premium feel.

2.Consumer Electronics: Casings that match high-end positioning.

3.Home Appliances: Glossy surfaces that attract customer attention.

4.Industrial Parts: Balanced functionality with improved aesthetics.

Conclusion

Improving Delrin gloss requires an integrated strategy of mold design, temperature management, and process parameter optimization. By addressing these factors systematically, parts can achieve both visual excellence and reliable performance. High-gloss Delrin products gain stronger recognition and trust in competitive markets.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!