Introduction

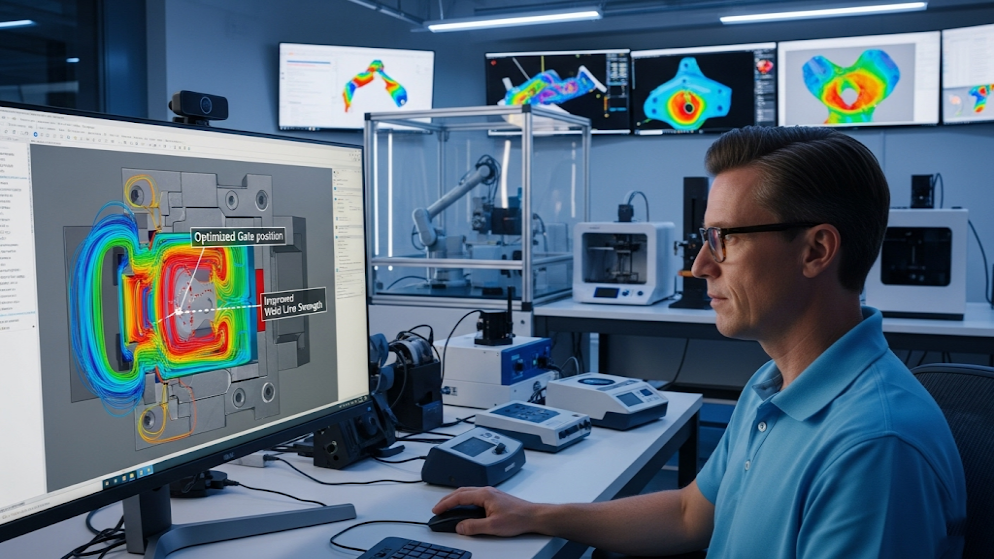

Mold design plays a crucial role in injection molding production, directly impacting product quality and production efficiency. In the process of improving weld line strength, proper mold design can effectively reduce defects and enhance durability. Good weld line design not only strengthens the product but also reduces rework rates.

By optimizing the mold, we can significantly improve weld line issues, thus enhancing the final product’s performance. Improving weld line strength is key to enhancing production efficiency and product quality.

How can optimizing gate position improve weld line strength?

The gate design directly determines the quality of the weld line. Improper gate placement during the injection molding process can lead to inconsistent weld line strength. Optimizing the gate position can effectively reduce weld lines and improve product strength.

- Choosing the best gate position: Prevent weld line formation, enhance overall strength

- Optimizing gate size and shape: Tailor gate size to material flow characteristics

- Reducing stress concentration during molding: How to adjust molds to reduce stress?

- Proper cooling system design: Ensure uniform cooling around the gate area to minimize cracking

✨ By adjusting the gate position and shape, we can significantly enhance weld line strength and reduce defects.

How does mold temperature control affect weld line strength?

Mold temperature directly affects material flow and solidification speed. Temperatures that are too high or too low can negatively impact the strength of the weld line. By precisely controlling mold temperature, we can optimize weld line strength.

- Proper mold heating: Ensure good material flow, minimize unevenness

- Temperature control system optimization: How to optimize mold temperature control

- Cooling speed and weld line: Manage cooling speed to prevent strength reduction

- Mold material selection: Choose materials suitable for high-temperature injection molding

🌡️ Controlling mold temperature is one of the key factors in improving weld line strength.

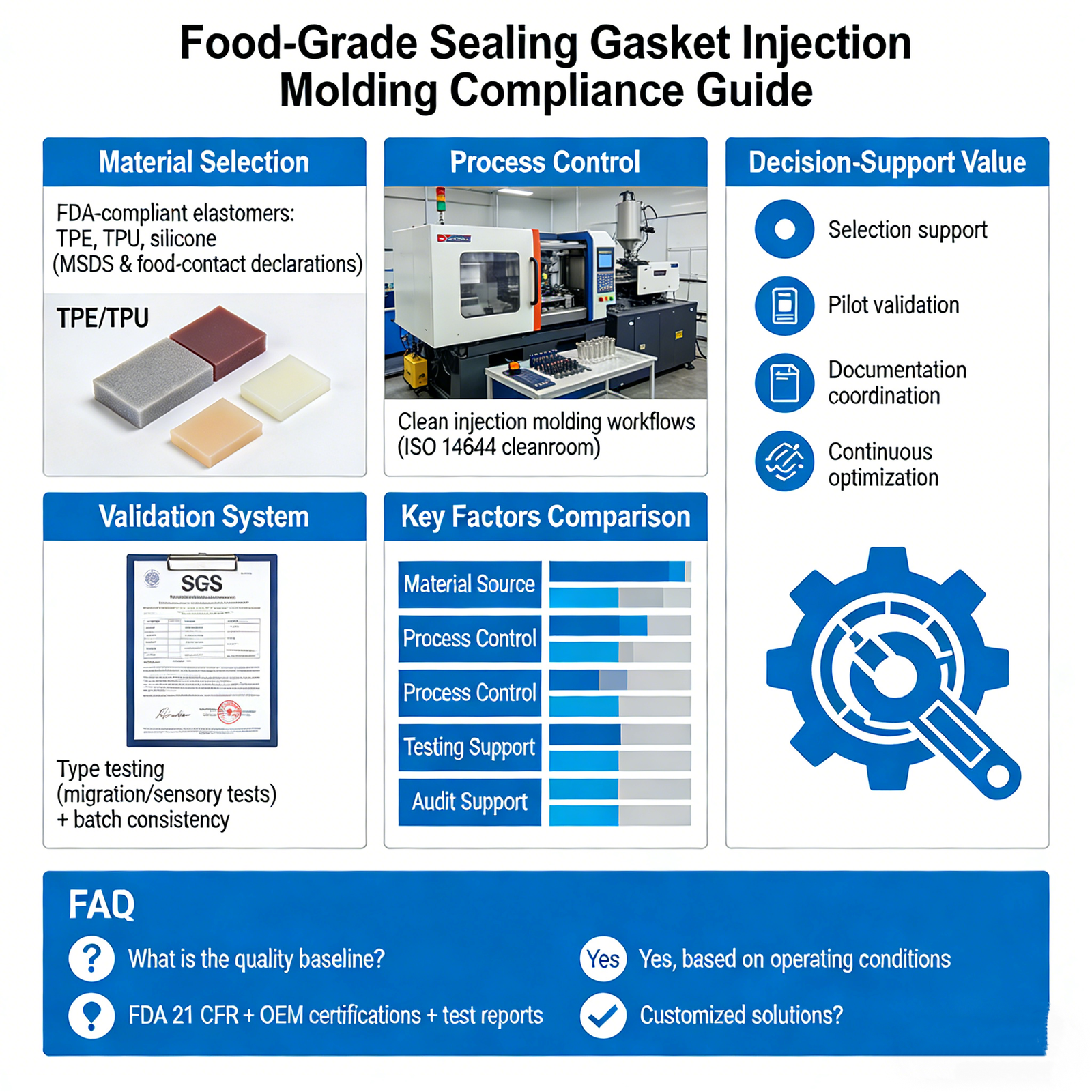

How does material selection impact weld line strength?

The material chosen directly impacts the appearance of the weld line. Some materials are more prone to weak points than others. Selecting the right injection molding material can significantly improve weld line strength.

- Choosing high-strength materials: Select materials with high tensile strength to increase product durability

- Optimizing material formulation: How to select the right formulation?

- Using reinforced plastics: Add reinforcing fibers to improve product strength

- Optimizing material flow: Adjust the formulation to ensure even material flow

💪 By selecting the right materials, we can effectively improve weld line strength and minimize future issues.

Table Title

| Mold Design Optimization Factor | Gate Position Optimization | Mold Temperature Control | Material Selection Optimization | Weld Line Strength Improvement |

|---|---|---|---|---|

| Gate Position Optimization | Excellent Design | - | - | High |

| Temperature Control | - | Precise Control | - | High |

| Material Selection | - | - | High-strength Materials | High |

| Cooling Design | - | - | - | High |

Key Techniques for Enhancing Weld Line Strength

Enhancing weld line strength is inseparable from proper mold design. By optimizing the mold structure, temperature control, and material selection, we can effectively improve weld line strength. Among these factors, reasonable mold design and precise temperature control are crucial. With these techniques, we can significantly improve product strength and quality.

1.Optimize gate position: Primary measure for enhancing weld line strength

2.Temperature control system design: Ensure uniform strength at weld lines

3.Material selection: Foundation for high-strength products

4.Cooling system design: Promote uniform cooling, minimize cracking

Conclusion

By optimizing mold design, we can significantly improve weld line strength, thus enhancing the overall quality of injection molded products. These optimization measures not only reduce product defects but also improve production efficiency.

For expert assistance in implementing these techniques for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!