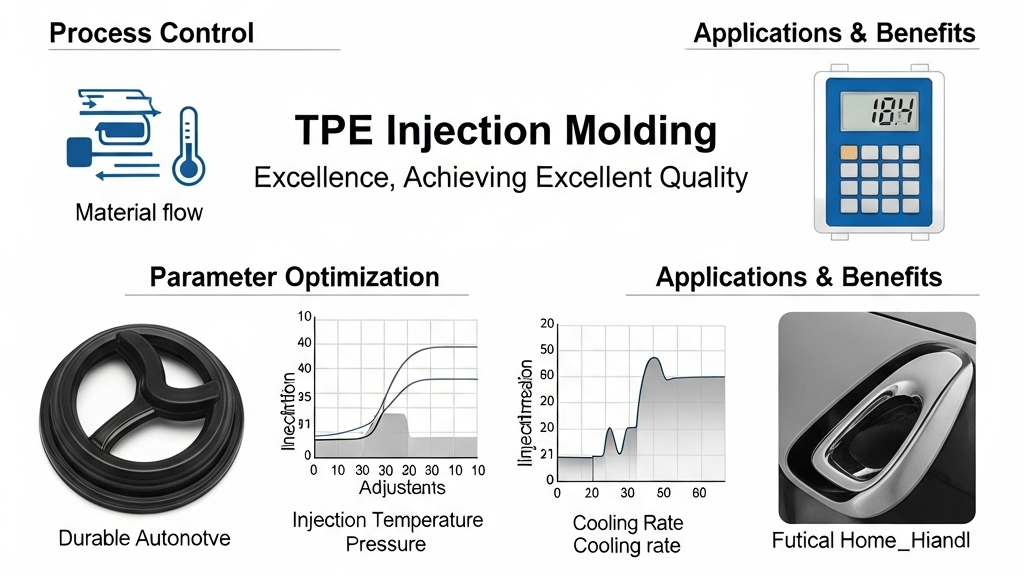

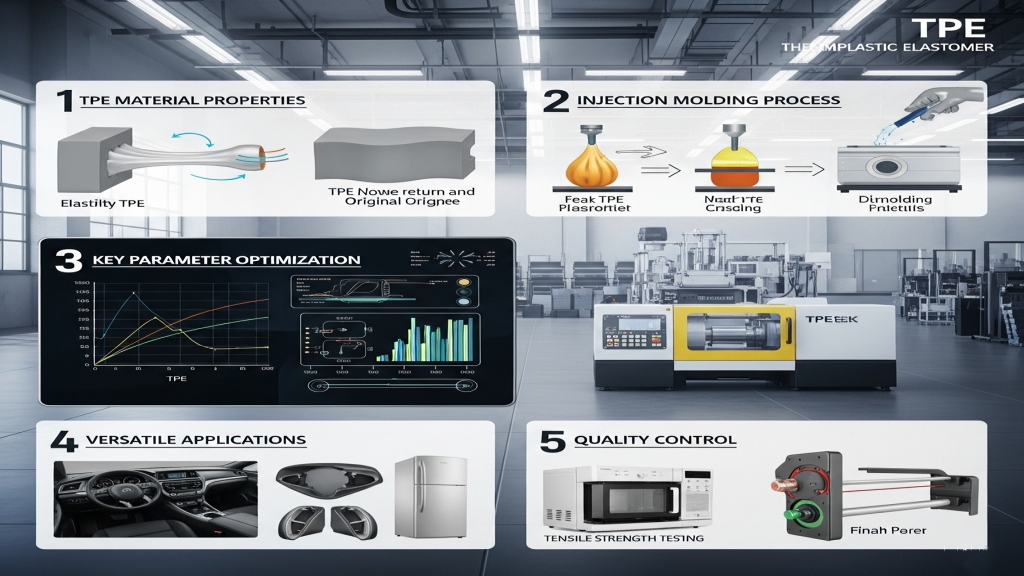

TPE (Thermoplastic Elastomer) is a material widely used in injection molding due to its unique elasticity and durability, making it suitable for applications in industries such as automotive and home appliances. Through precise injection molding processes, TPE not only maintains its elasticity but also enhances the material's mechanical properties and durability. The injection molding process is key to achieving TPE properties, as it effectively regulates factors such as material flow and temperature control, ensuring the final product's quality and stability.

In the molding process, adjusting the physical properties and processing parameters of TPE is crucial. Choosing the right injection temperature, pressure, and cooling speed allows for maximizing TPE's advantages and meeting the functional requirements of various applications.

How Does Injection Molding Affect TPE's Elasticity and Durability?

Injection molding significantly impacts TPE's elasticity and durability. By controlling molding parameters, the material's flowability, molding pressure, cooling speed, and other factors can be adjusted, influencing its elasticity and durability. Fine control of these processes ensures TPE achieves optimal elasticity and durability, making it suitable for various application needs.

- Injection Temperature Control: Affects TPE's flowability and final physical properties.

- Molding Pressure: Injection Pressure and TPE Performance is crucial.have a significant relationship.

- Cooling Rate: Cooling speed directly affects TPE's mechanical properties.

- Mold Design: Proper mold design can enhance product structural stability.

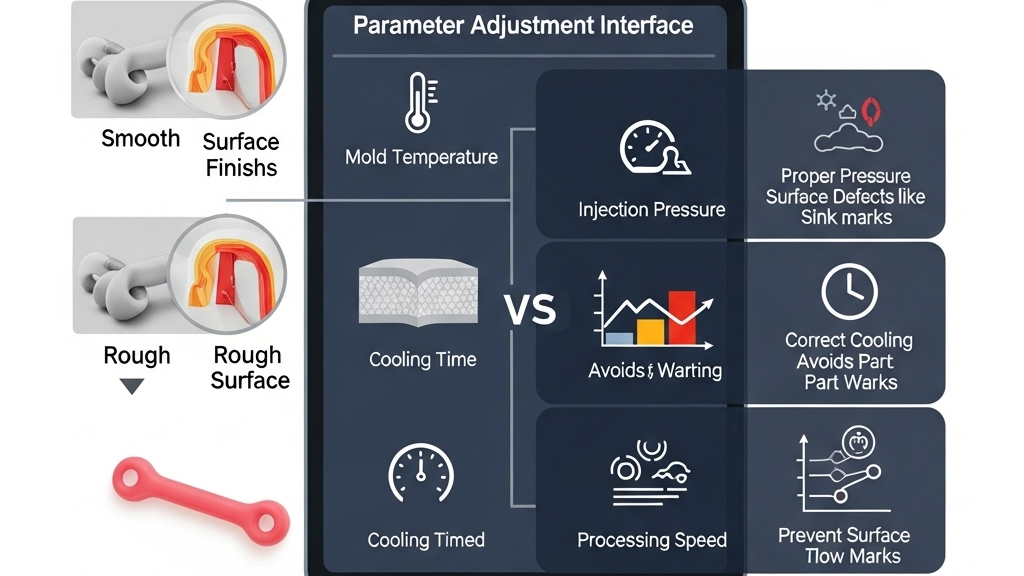

How to Control TPE's Surface Smoothness Through Injection Molding?

The surface smoothness of TPE is a key factor affecting its appearance and tactile feel. By adjusting molding parameters such as temperature, pressure, and cooling speed, TPE's surface smoothness can be effectively controlled. Appropriate injection parameters can improve TPE's surface quality, enhancing the product's aesthetics and functionality.

- Mold Temperature: Temperature extremes can affect surface quality.

- Injection Pressure: The Effect of Pressure on Surface Smoothness is crucial.

- Cooling Time: Cooling time controls the final surface effect.

- Processing Speed: Faster injection speeds can impact surface smoothness.

Common Issues in TPE Injection Molding and Solutions

Common issues in TPE injection molding include air bubbles, flow marks, and shrinkage. These issues can be effectively prevented by adjusting molding parameters. Applying appropriate solutions to different problems can significantly enhance production efficiency.

- Air Bubble Issue: Adjusting injection speed and temperature to avoid air entrapment.

- Flow Mark Issue: Optimizing runner design to reduce flow resistance.

- Shrinkage Issue: Solutions to Shrinkage Issues include controlling temperature and cooling.

- Short Shot Issue: Increasing injection pressure to ensure full mold filling.

TPE Injection Molding Process Parameter Comparison Table

| Parameter | Temperature Control | Pressure Control | Cooling Control | Mold Design |

|---|---|---|---|---|

| Elasticity Impact | High temperature aids flow | High pressure enhances elasticity | Rapid cooling improves elasticity | Precise design improves stability |

| Durability Impact | High temperature lowers durability | Moderate pressure increases durability | Cooling rate affects durability | Optimized mold prevents defects |

| Surface Effect | High temperature aids smoothness | High pressure improves surface quality | Cooling rate determines surface quality | Mold design improves appearance |

| Common Issues | High temperature causes bubbles | Low pressure causes shrinkage | Slow cooling leads to surface issues | Inaccurate molds lead to defects |

How to Optimize TPE Properties Through Injection Molding?

By precisely controlling the injection molding process, TPE materials' elasticity, durability, and appearance can be effectively optimized. Proper process adjustments enhance overall TPE performance, ensuring that products meet expected standards and functional requirements.

1.Control Injection Temperature: Temperature adjustments prevent bubbles and flow marks.

2.Optimize Injection Pressure: Ensure moderate pressure to avoid shrinkage and surface issues.

3.Cooling Control: Proper cooling rate improves material uniformity.

4.Fine Mold Design: Mold design is crucial for ensuring final product quality.

Conclusion

Optimizing TPE injection molding not only enhances its elasticity and durability but also improves surface quality. Fine-tuning process parameters ensures that TPE performs excellently in practical applications, meeting diverse production needs. Injection molding plays an irreplaceable role in achieving TPE properties, and with advancements in technology, TPE applications will become even more widespread.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!