Ignoring the heat deflection temperature (HDT) of materials at the design stage can result in deformation or cracking of plastic parts during use. HDT not only determines the upper heat limit of the material but also relates to the safety and reliability of the structure. Confirming HDT parameters is essential for stable performance under high-temperature conditions.

Different plastics behave differently under thermal load. In high-pressure or loaded conditions, choosing the wrong HDT level may lead to irreversible damage. HDT is not just a number, but a crucial metric in risk management.

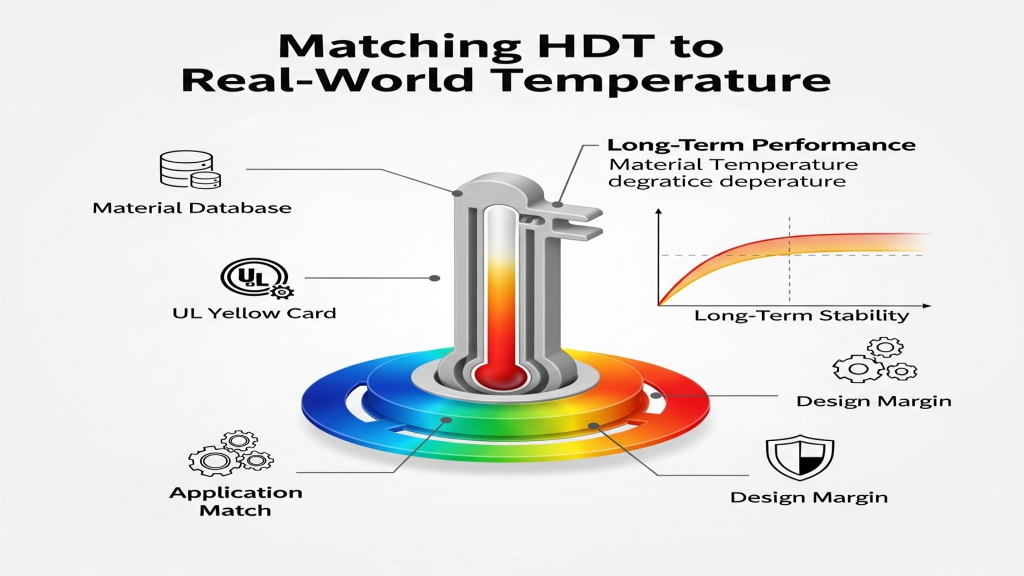

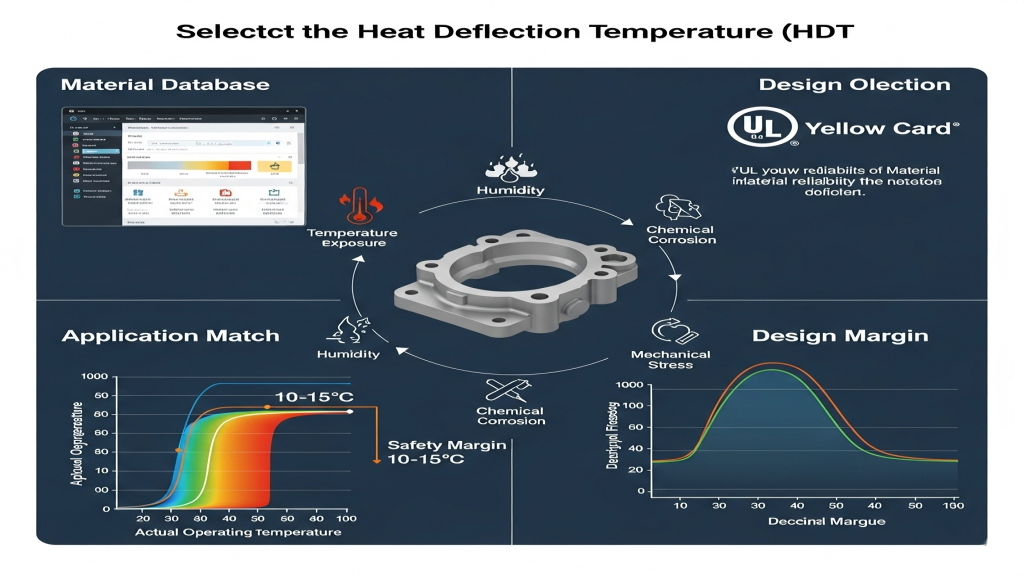

Can the HDT withstand real-world temperatures?

HDT should not be selected based on the highest value but rather matched with real application temperatures. Long-term thermal stability is the true test of qualification. Overlooking environmental factors leads to rapid performance degradation.

- Material Database: For quick HDT reference.

- UL Yellow Card: Reliable data for material selection.

- Application Match: HDT should exceed service temperature by 10–15°C.

- Design Margin: Consider stress and thermal fatigue over time.

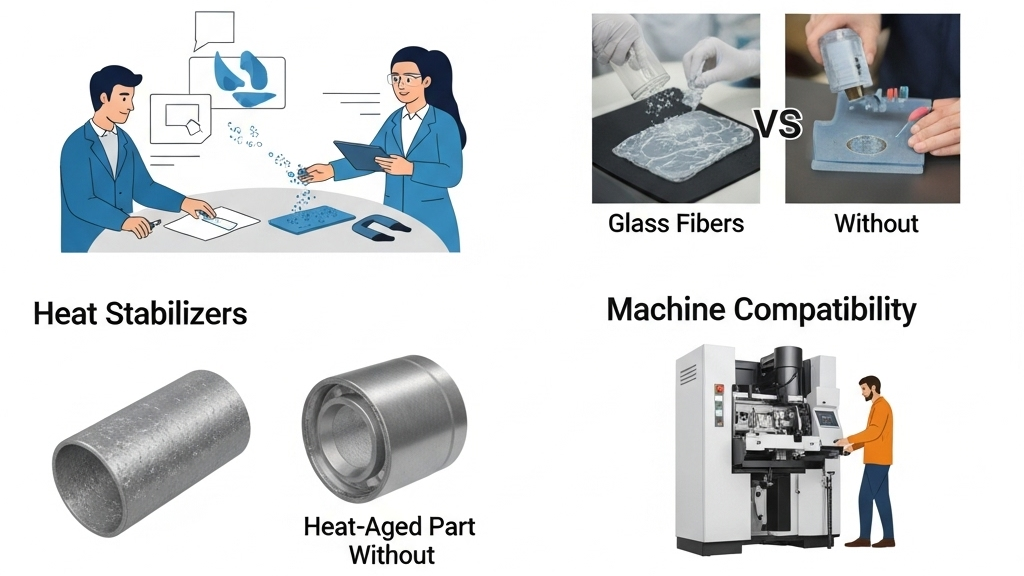

How much does HDT vary with the same thickness?

Even with the same thickness, HDT varies greatly depending on polymer structure, fillers, and crystallinity. Materials like ABS, PC, PPS, and PA perform vastly differently. Choosing the wrong material early in design impacts service life.

- Material Handbook: Compare HDT values across resins.

- Structural Reinforcement: Ribs help boost thermal stability.

- Material Modification: Fiber glass filling can improve HDT.

- Process Optimization: Molding temp and cooling rate affect HDT.

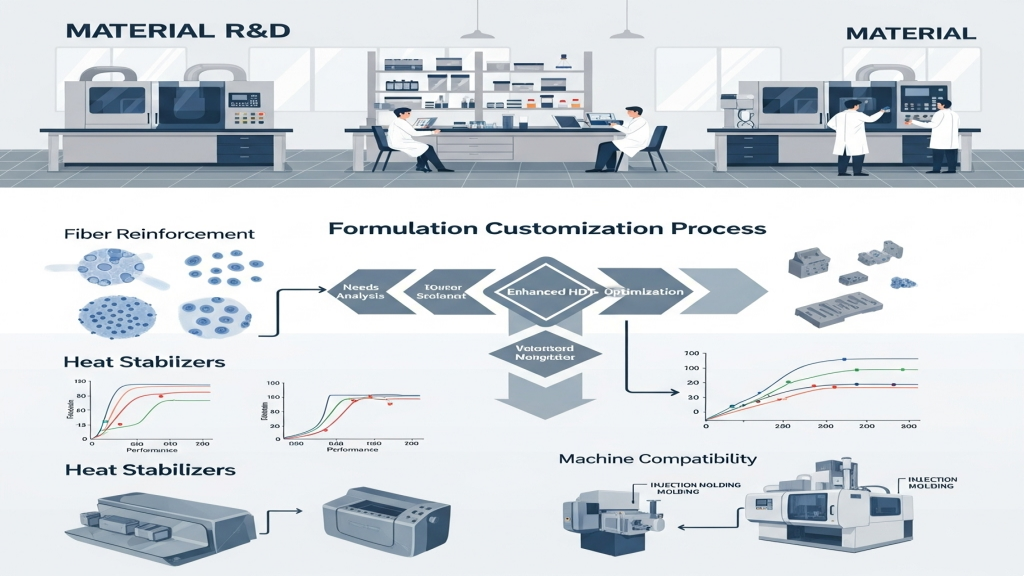

Can we customize the formulation to boost HDT?

If standard materials fall short, formulation customization via blending or additives is key. The challenge lies in balancing additives and dispersion techniques.

- Consult a Specialist: Get custom HDT solutions.

- Fiber Reinforcement: Glass fiber significantly improves HDT.

- Heat Stabilizers: Prevent aging under thermal load.

- Machine Compatibility: High-HDT resins require compatible injection machines.

Comparison Table of HDT for Common Engineering Plastics

| Material | HDT @1.8MPa(℃) | HDT @0.45MPa(℃) | Modifiable | Application | Thermal Stability | Cost Level | Processing Difficulty |

|---|---|---|---|---|---|---|---|

| ABS | 85 | 98 | No | Housings | Medium | Low | Low |

| PC | 130 | 140 | Yes | Lighting covers | High | Medium | Medium |

| PPS | 230 | 260 | Yes | Automotive engine area | Very High | High | High |

| PA66+GF | 250 | 265 | Yes | Structural parts | High | Medium-High | High |

Importance of HDT Testing and Validation

After material selection, HDT validation ensures final product reliability. For critical structures, theory alone is not sufficient. Testing is essential to prevent performance failure.

1.Standard Tests: Based on ISO 75 or ASTM D648.

2.Batch Testing: Prevent performance gaps from material differences.

3.Thermal Simulation: Evaluate structure under heat in simulations.

4.Prototype Validation: Mold and test real part response.

Conclusion

Confirming a plastic's HDT is not just part of material selection — it’s the foundation of reliable product design. HDT must align with the use environment, structural form, and load conditions. Every stage from design to validation should align with HDT logic.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!