Introduction

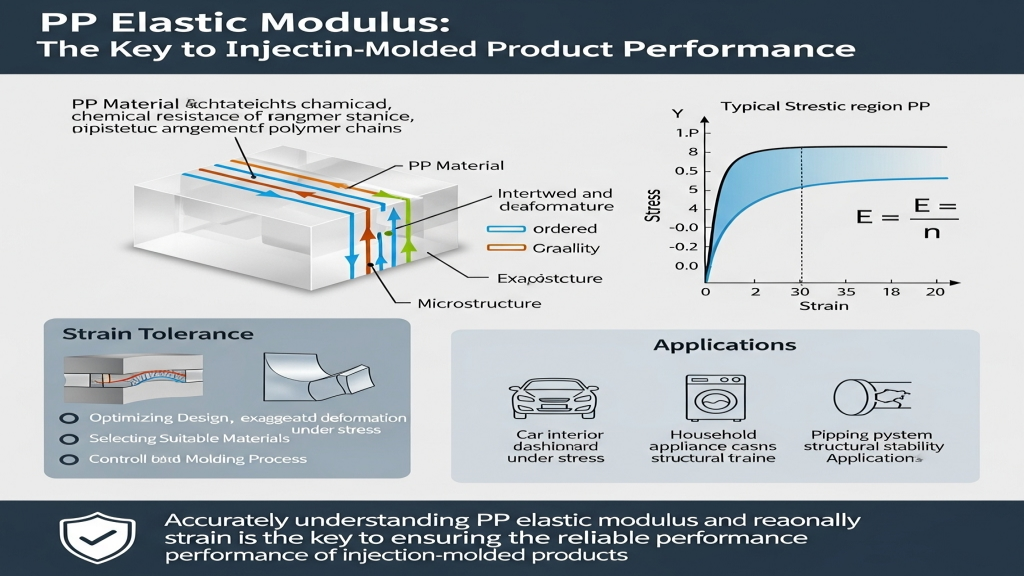

Polypropylene (PP), as a widely used thermoplastic, relies on its elastic modulus to define the rigidity and durability of the end product. In injection-molded components for automotive, appliances, and piping systems, deformation capacity affects both structural stability and service life.Accurate understanding of the modulus is critical to achieving dependable product performance.

Meanwhile, the strain tolerance of PP determines its resistance under peak loads. This is influenced not only by material properties but also by stretching, bending, or impact during the molding process.Controlling strain is key to preventing early failure of injection-molded products.

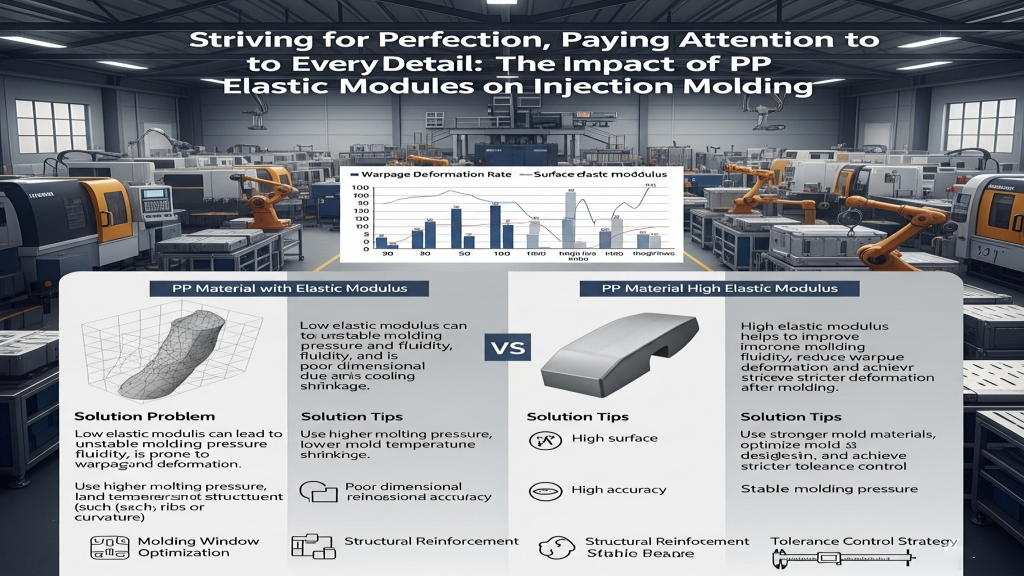

How does PP’s elastic modulus affect injection molding?

Elastic modulus influences how PP deforms under force during the injection process, impacting dimensional stability and mechanical properties of the molded parts. A lower modulus can lead to warpage during cooling and shrinkage, reducing assembly accuracy.Modulus levels also dictate the design strategy for thickness and rib placement.

- Molding Window Optimization: Modulus affects molding pressure and flow.

- Mold Steel Selection: High modulus demands stronger mold materials.

- Structural Reinforcement: Ribs or curvature are required for low modulus parts.

- Tolerance Control Strategy: Higher modulus enables tighter tolerances.

🔧 Mastering modulus is the foundation of strong structural design in injection molding.

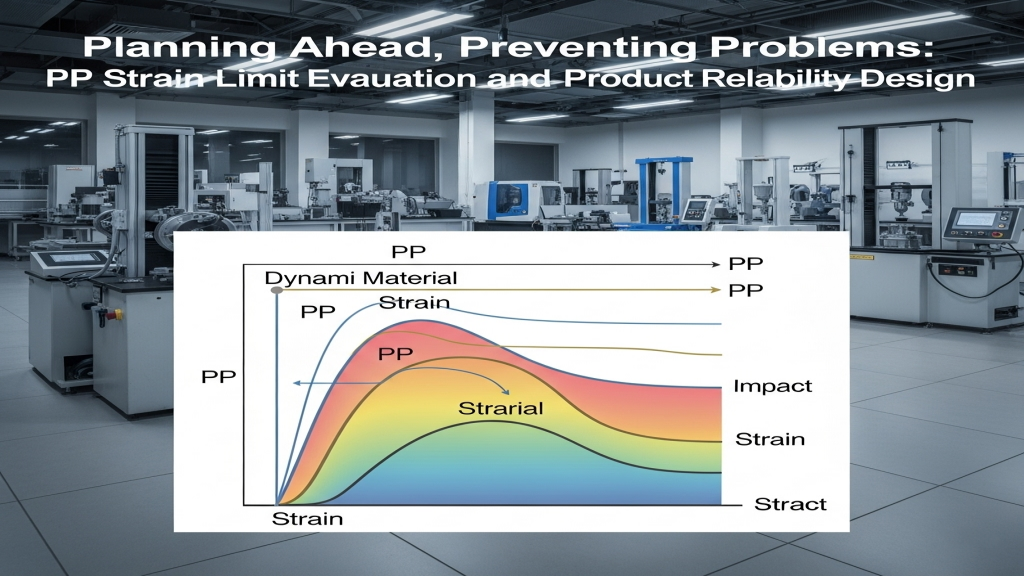

How to evaluate if PP’s strain limit meets your product requirements?

The strain limit of PP depends on the grade, formulation, and actual service load. Exceeding this limit can cause permanent deformation or cracks, especially under dynamic or impact loading.Accurate strain assessment is essential for reliable product performance.

- High-Strain Application Recognition: Thin-walled containers and living hinges require high strain.

- Fatigue Life Prediction: Repeated stress calls for strain-based safety design.

- Pre-Failure Safety Margins: Set conservative limits to prevent failure.

- Lab Strain Testing: Tensile tests define true material limits.

📈 Understanding PP’s strain ceiling helps avoid stress-induced product failures.

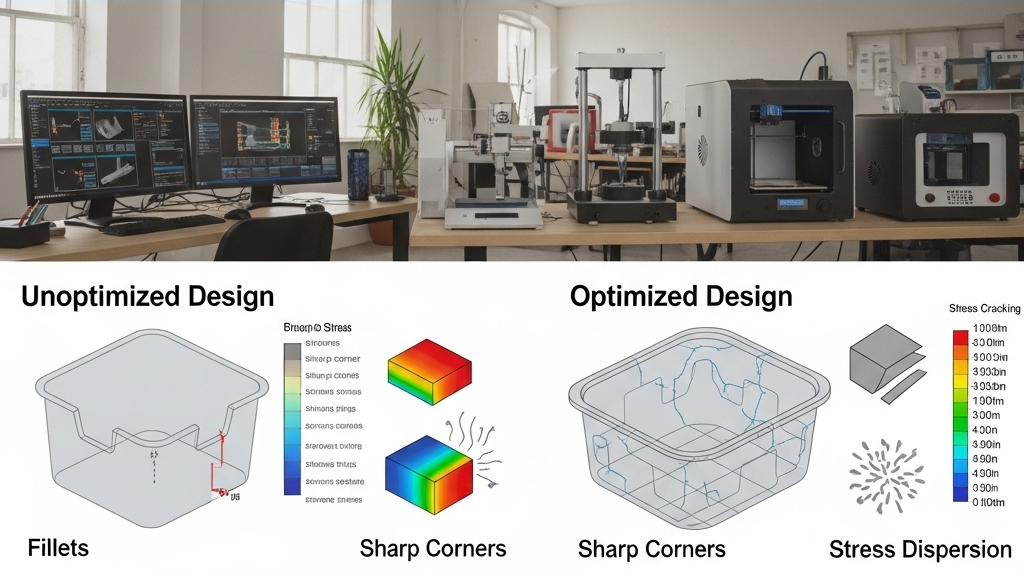

How can design be optimized to balance modulus and strain in PP parts?

Balancing stiffness and flexibility is key in product design. PP has low modulus but good elongation, which can be improved by adding glass fiber or using copolymer blends.Material selection, use environment, and molding process must work together for optimal results.

- Blending Optimization: Copolymer or filler modifications adjust modulus.

- Stress Distribution Design: Use fillets and ribs to avoid stress points.

- Wall Thickness Transitions: Smooth variations reduce strain risk.

- Flow Simulation Tools: Predict stress/strain concentrations before production.

🛠️ Reliable structure begins with thoughtful material and geometry integration.

Modulus and Strain Performance of PP

| Material Type | Modulus (MPa) | Strain at Break (%) | Glass-Filled | Shrinkage Rate | HDT (°C) | Toughness | Application Use |

|---|---|---|---|---|---|---|---|

| Homo PP | 1400 | 12 | No | 1.5% | 90°C | Good | Daily-use housings |

| Co-PP | 1100 | 30 | No | 1.8% | 85°C | Excellent | Living hinges, auto trims |

| Glass-Filled PP | 5000 | 3 | Yes | 0.7% | 125°C | Fair | Automotive structures |

| High-Rigidity PP | 3200 | 8 | Yes | 1.0% | 110°C | Medium | Appliance frames |

Extended Analysis

The balance between rigidity and flexibility makes PP essential in many industries. By modifying formulations and additives, modulus and strain can be tailored to meet diverse mechanical and design needs.Especially in automotive and appliance injection parts, PP offers versatile structural freedom.

1.Rigidity Boosting: For load-bearing and structural components.

2.Flexibility Utilization: Great for thin-walled or living hinge applications.

3.Mature Blending Techniques: Widely applied in dual-function parts.

4.Lightweight Advantage: Supports sustainability and weight reduction goals.

Conclusion

PP demonstrates outstanding capability in balancing stiffness and flexibility for injection-molded applications. Its elastic modulus and strain tolerance allow designers to create parts that are lightweight, cost-effective, and durable.Material engineers must choose the right PP formulation based on application-specific requirements.A solid understanding of these two parameters guides both design and tooling optimization.This leads to reliable, high-performance, and scalable product solutions.

For expert assistance in implementing PP-based solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!