Introduction

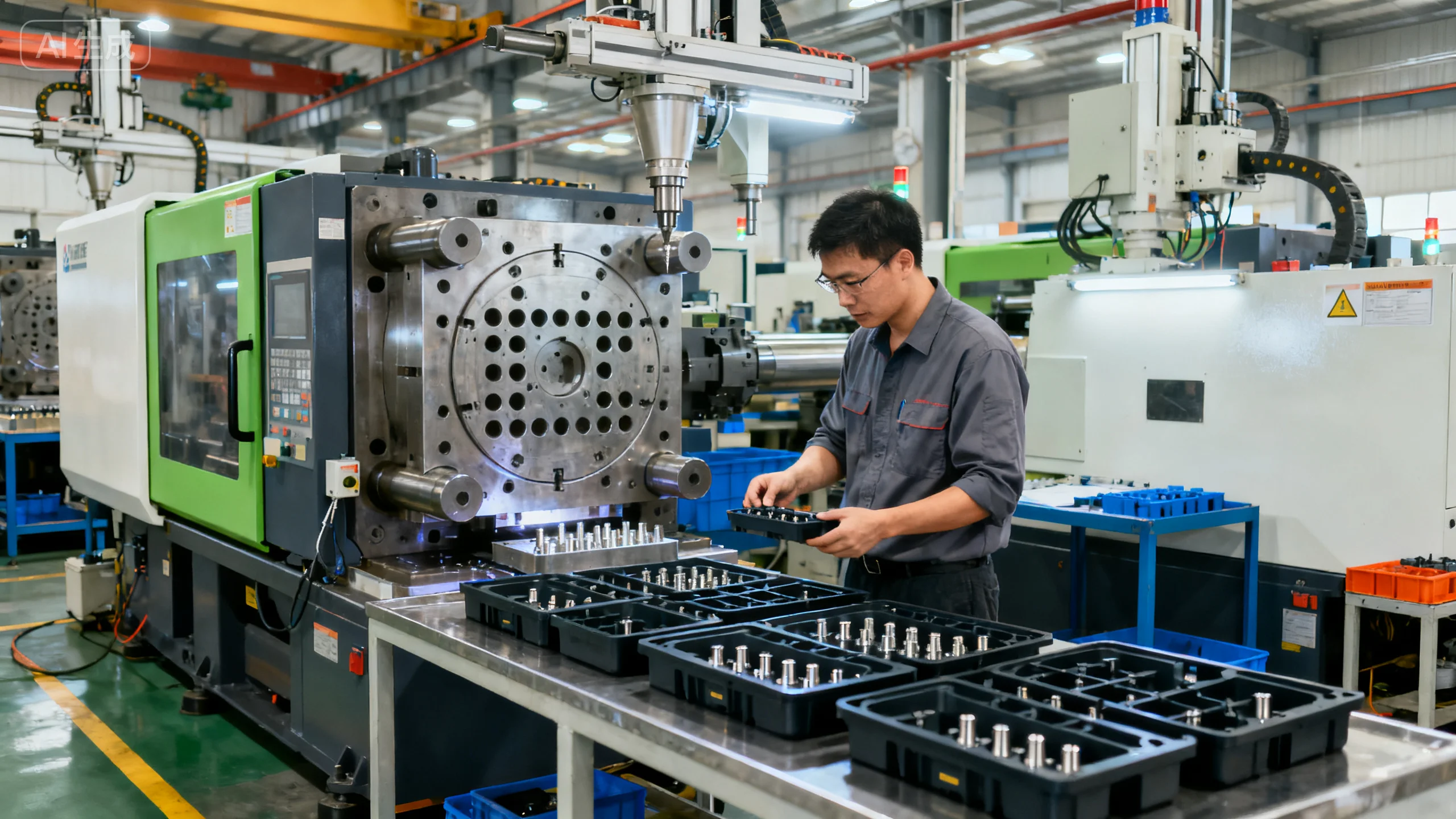

Micro nylon washers are widely used in electronics, electrical appliances, and automotive applications, but their molding process is full of difficulties. The miniaturization of parts makes processing accuracy and mold durability the core concerns. In precision parts production, stable quality output is the key for companies to win the market.

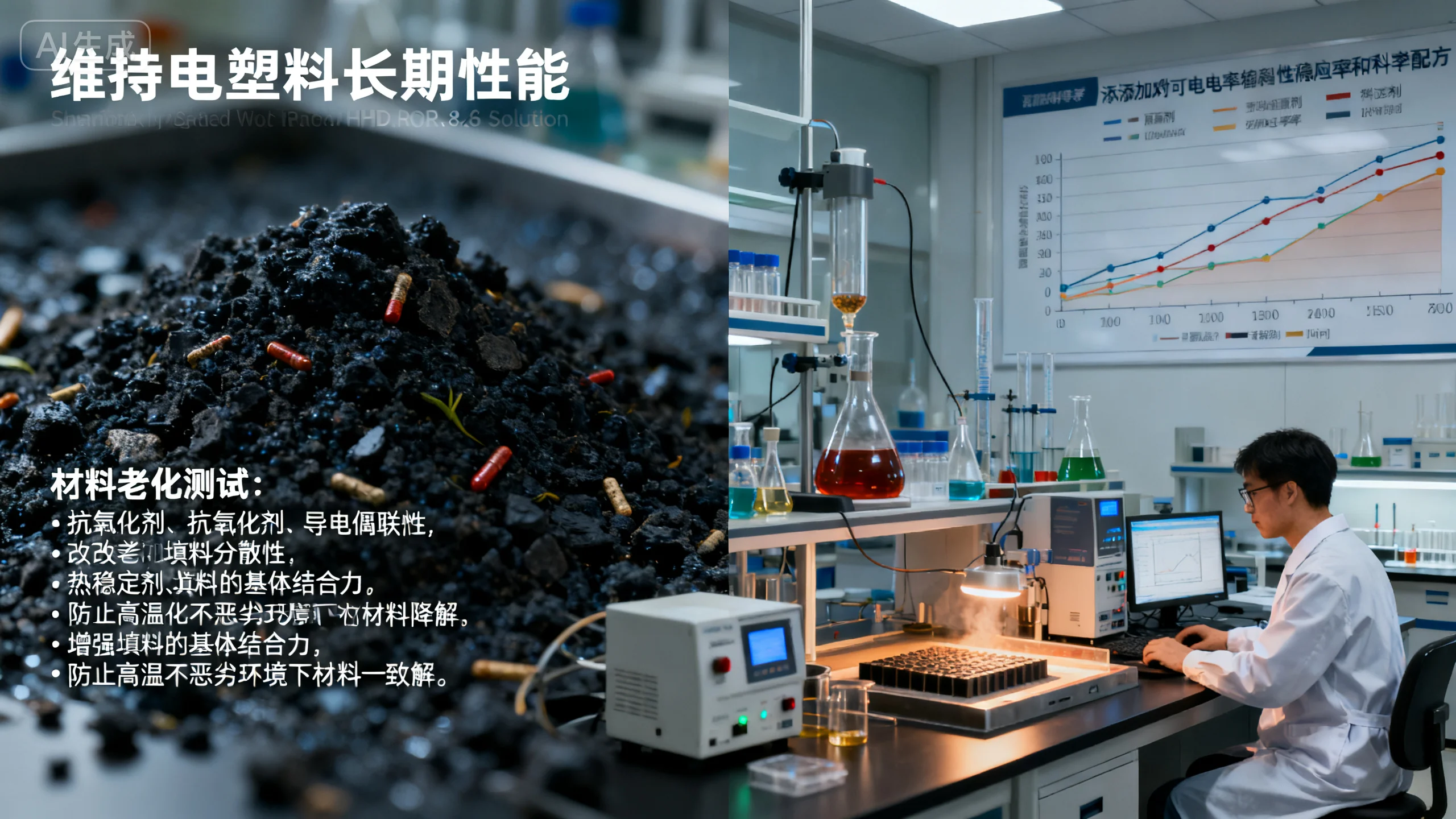

In addition, nylon’s hygroscopic nature, flow behavior, and cooling shrinkage make process control even more complex. Manufacturers must ensure cost-effectiveness while maintaining mass production capability. The reliability of these components directly affects the performance of downstream products.

Why do micro nylon washers deform easily?

During injection molding, nylon is highly susceptible to dimensional changes caused by temperature and pressure. Micro washers often deform due to uneven wall thickness, unstable cooling, or fiber orientation. Such dimensional deviation becomes a severe quality risk in mass production.

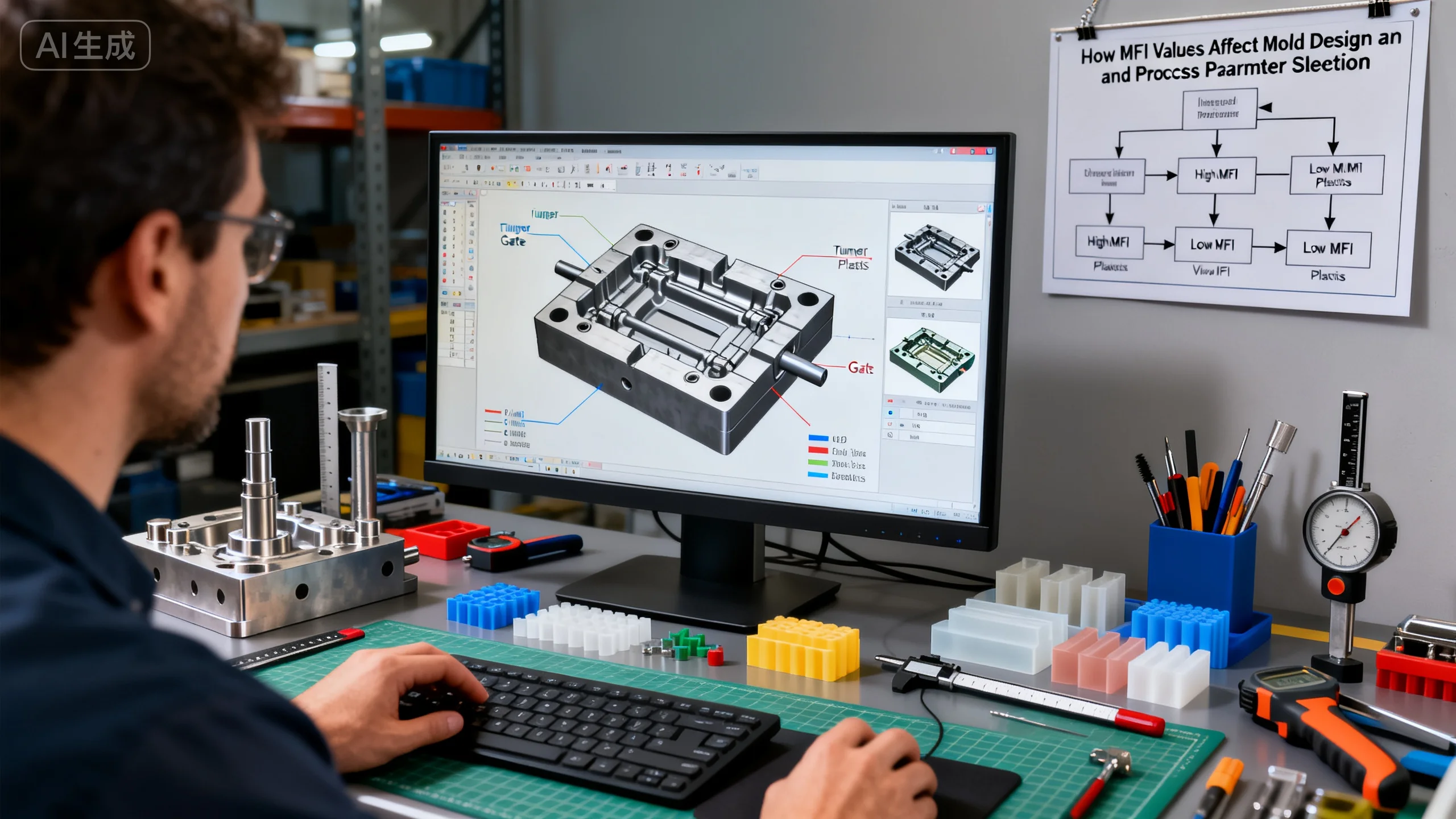

- Mold design optimization: Proper gate and runner design reduces deformation

- Material modification: Glass fiber reinforcement improves dimensional stability

- Cooling system adjustment: Accurate cooling minimizes shrinkage stress

- Process monitoring: Real-time control of injection parameters ensures consistency

😊 Deformation in micro nylon washers is mainly controlled through the synergy of material and process

Why do micro nylon washers often have burrs?

Nylon melt under high pressure tends to flash through mold parting lines. For micro parts, even tiny mismatches in mold fit can magnify into defects. Burrs not only affect appearance but also compromise assembly accuracy and service life.

- Mold precision control: Ensure parting line fit accuracy

- Clamping force optimization: Proper clamping force prevents flash

- Material drying: Lower moisture to avoid abnormal melt flow

- Process balance: Precisely set injection speed and holding time

🔧 Eliminating burrs requires dual control of mold precision and process parameters

Why is it difficult to ensure dimensional consistency of micro nylon washers?

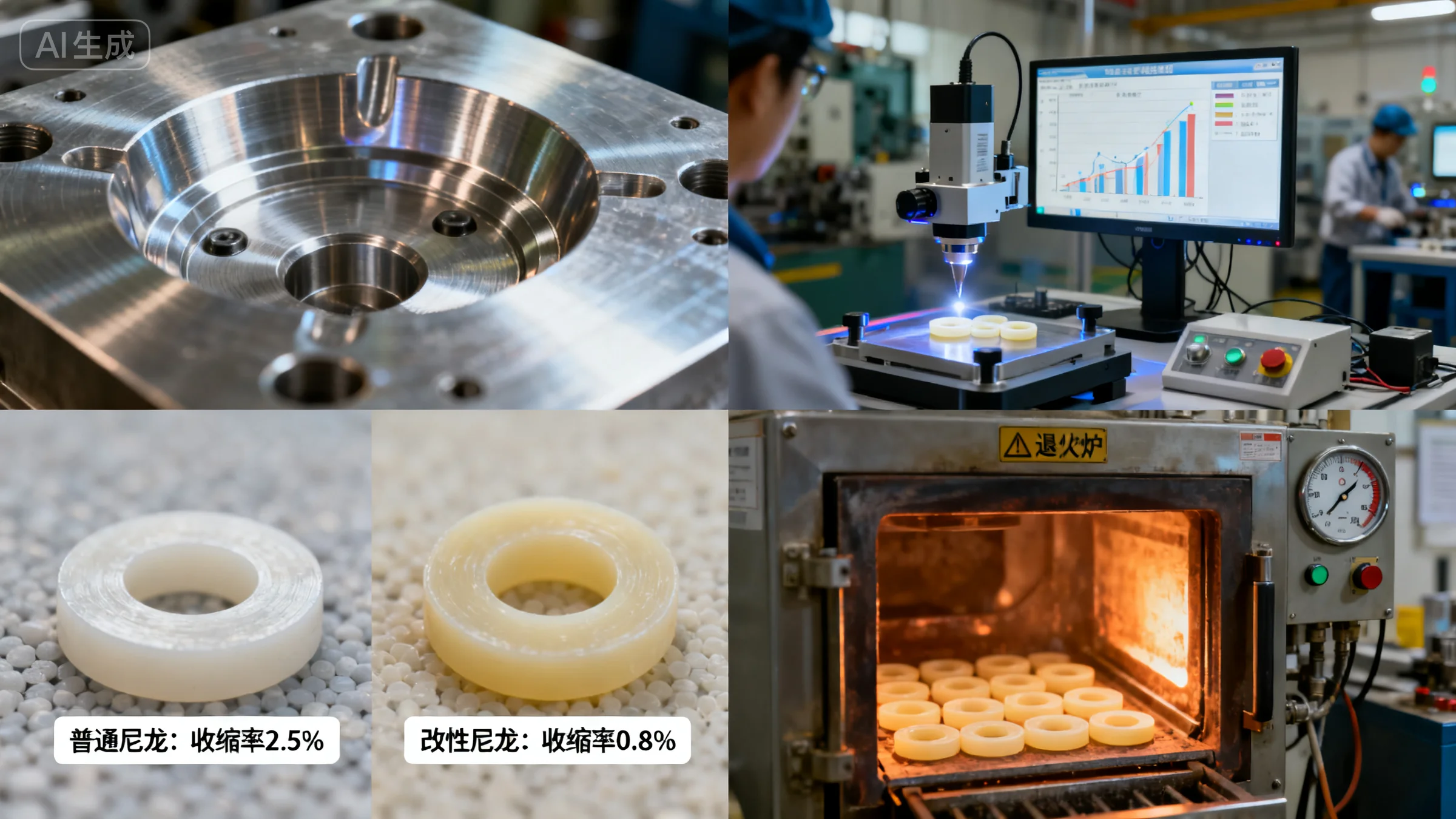

Due to nylon’s high shrinkage and hygroscopic nature, molded parts may experience size deviations during cooling and later use. Micro washers demand extremely tight tolerances, which is a great challenge for process capability. Dimensional consistency directly determines assembly efficiency and final product performance.

- Mold cavity optimization: Micron-level tolerance design ensures accuracy

- Online inspection: Real-time monitoring of product dimensions

- Material selection: Low-shrinkage modified nylon enhances stability

- Post-processing: Annealing reduces internal stress and deformation

📏 Dimensional consistency is the key to mass production of micro nylon washers

Production process comparison for micro nylon washers

| Process Type | Precision | Cost Level | Defect Rate | Production Scale |

|---|---|---|---|---|

| Conventional | Medium | Low-Medium | High | Large-scale |

| Micro Molding | High | High | Low | Small-Medium |

| Hot Runner | High | Medium-High | Low | Large-scale |

| Secondary Machining | Ultra High | Ultra High | Ultra Low | Small-scale |

Selecting the right process path is the key to balancing cost and performance. For more solutions please contact us.

Expansion

The demand for micro nylon washers is growing rapidly along with electronics and new energy industries. Customers are increasingly requiring lightweight, wear-resistant, and reliable parts. In this trend, injection molding technology must keep innovating to achieve higher precision mass production.

1.Smart manufacturing: Automation and AI improve consistency

2.New materials: Modified nylon improves properties

3.Green process: Reduces energy consumption and scrap rate

4.Customized service: Tailor-made molds and solutions

Conclusion

The key challenges in molding micro nylon washers are deformation, burrs, and dimensional control, which require integrated optimization of molds, materials, and processes. Only by achieving breakthroughs in process stability and innovation can companies stand out in a highly competitive market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!