Resin 3D printing is favored for its ability to manufacture complex and high-precision parts. However, overhanging structures and complex curved surfaces require support structures to assist in printing. Support design directly affects printing success rates and model quality. In-depth exploration of the design and removal of supports in resin 3D printing is crucial and can provide technical guidance for the industry.

Support structures are essential in resin 3D printing. Next, we will discuss the core principles and strategies of support design. An excellent support system needs to comprehensively consider model geometry, stress, material, and post-processing. From support type selection to parameter optimization and software-intelligent generation, each step requires careful consideration. Understanding and applying these design elements is the key to improving printing quality and efficiency.

The Necessity and Role of Supports?

Support structures play a crucial role in resin 3D printing. Like scaffolding in construction, they provide the necessary physical support for overhanging geometries and fragile structures, ensuring that the model does not fail due to gravity or deformation during the layer-by-layer curing process. Without solid supports, many complex designs would be impossible to achieve, and the printing quality would be greatly reduced.

- Supports are key to achieving complex shapes: Support structures, like bones, support complex geometries and prevent deformation and collapse during printing.

- Supports solve overhanging structure problems: For overhanging, bridging, or steep-angle designs, supports resist gravity and ensure correct layer-to-layer connections.

- Supports ensure printing accuracy and quality: Supports provide a stable base for uncured resin layers, directly affecting model accuracy and surface quality.

- Supports break through design physical limitations: Support structures overcome physical limitations, enabling complex designs that surpass traditional manufacturing processes.

Main Support Types and Their Characteristics?

In resin 3D printing technology, various types of support designs have been developed to cope with various complex model structures. These supports are not all the same. Instead, they exhibit their own unique characteristics based on their shape, function, and contact method with the model to adapt to different printing needs and optimize the final printing effect.

- Diversity of Main Support Types: Resin 3D printing mainly includes point supports, linear supports, block supports, and raft supports to address different printing challenges.

- Refined Characteristics of Point Supports: Point supports have a small contact area, reducing surface impact. They are suitable for areas requiring high surface finish, but their stability may be slightly weaker.

- Stability of Linear Supports: Linear supports are columnar or grid-like, providing more stable support force and are often used for larger overhanging areas or connecting model parts.

- Strong Load-Bearing Capacity of Block Supports: Block supports have a large contact area, providing strong support. They are suitable for parts that bear gravity or require extra stability, but removal marks may be more obvious.

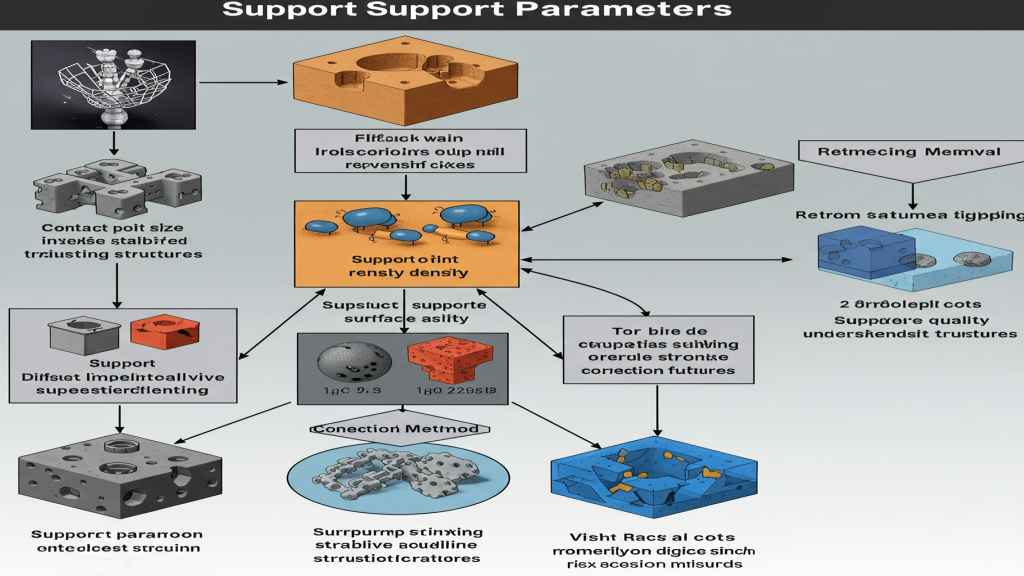

Relationship Between Support Parameters and Printing & Removal?

Fine-tuning support parameters is a crucial part of resin 3D printing, directly affecting the stability of the printing process and the quality of the final model. Reasonable support parameter settings can not only ensure successful printing of the model but also significantly reduce post-processing difficulty, improve the efficiency of support removal, and enhance the integrity of the model surface.

- Trade-off between contact point size and stability, removal difficulty: Smaller contact points are easier to remove but may be unstable, while larger contact points are stable but more difficult to remove.

- Relationship between support density and strength, cost: High-density supports have high strength but consume more material, while low-density supports are the opposite.

- Influence of support angle on stability and surface quality: A reasonable support angle reduces the stepping effect, but excessive inclination may lead to unstable supports.

- Connection method affects support strength and removal convenience: Connecting beams and bases enhance support strength but also affect the convenience of removal.

Types and parameters of resin 3D printing support

| Feature/Parameter | Point Support | Linear Support | Block Support | Raft Support |

|---|---|---|---|---|

| Main Features | Small contact point, thin pillar | Line-shaped or grid-like | Large contact area, blocky | Large base, connects model bottom |

| Applications | Rich details, high surface finish | Large overhangs, connects model parts | Large load-bearing, requires extra stability | Improves adhesion, uneven bottom surface |

| Support Strength | Relatively weak | Good | Strong | Stronger |

| Material Usage | Low | Medium | High | High |

| Removal Difficulty | Relatively easy | Medium | Difficult | Difficult, bottom may be uneven |

| Surface Impact | Minimal | May have line marks | Obvious marks | Model bottom may have marks |

| Key Parameters | Contact point size, support density | Support density, line width, spacing, angle | Contact area size, thickness | Thickness, edge width, connection method |

| Impact on Printing | Small point easy to break, low density insufficient support | Low density insufficient support, improper angle easily deformed | Small area insufficient support, insufficient thickness easily deformed | Insufficient thickness poor adhesion, improper connection difficult to separate |

| Impact on Removal | Large point difficult to remove | High density difficult to separate, large line width obvious marks | Large area difficult to remove, large thickness difficult to remove | Tight connection difficult to separate, large thickness difficult to remove |

Efficient Removal Methods and Future Development

Efficient support removal is a critical step in the post-processing of resin 3D printing, directly affecting the quality of the final product and production efficiency. Currently, easy-to-peel support materials, soluble support materials, and more precise tools and automated removal solutions are constantly emerging, aiming to reduce manual labor and minimize model damage.

1.Easy-to-Peel and Soluble Materials: Researching and applying easy-to-peel and soluble support materials can significantly reduce removal difficulty and minimize model damage.

2.Precision Tools and Automation: More precise tools and automated solutions aim to improve the accuracy and efficiency of support removal, replacing manual operations.

3.Intelligent Support Design: Intelligent support design will generate fewer, easier-to-remove structures and optimize collaboration with printing parameters.

4.New Post-Processing Technologies: Exploring new post-processing technologies, such as chemical dissolution and automated control, will build a more intelligent removal process.

Conclusion

The widespread application of resin 3D printing technology is inseparable from a deep understanding and continuous optimization of support design and removal. As a key auxiliary means for printing complex geometric shapes, the necessity of support structures cannot be ignored. They can effectively solve forming problems such as overhangs and bridging, ensuring the success rate of printing and the quality of the model.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!