Introduction

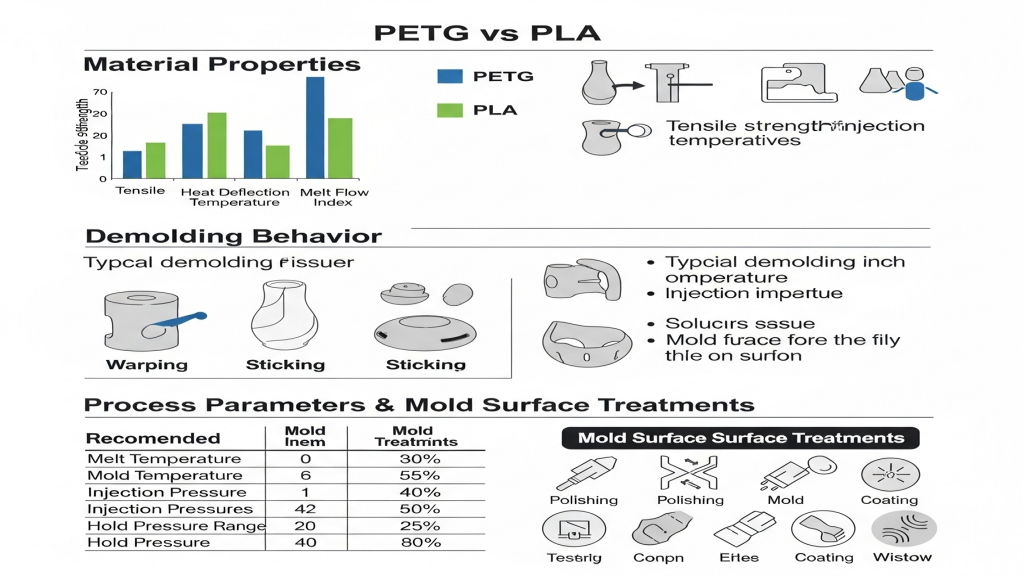

PETG and PLA exhibit distinct demolding behaviors in injection molding, driven by their physical properties and processing conditions. Selecting the right process parameters can significantly reduce defects during demolding, improving production efficiency and product consistency. Matching mold surface treatment with material characteristics is a critical factor in this process.

In mass production, PETG offers greater stability during demolding due to its toughness and heat resistance, while PLA requires precise temperature control because of its brittleness and lower melting point. This means that material properties directly determine the demolding plan. Understanding these differences is crucial for optimizing injection molding operations.

What are the key precautions when demolding PETG?

PETG relies heavily on mold surface smoothness and temperature control during demolding, as poor control can lead to surface scratches or sticking. Properly adjusting mold temperature and using suitable release agents can greatly reduce scrap rates. Uniform cooling during the process also affects demolding smoothness.

- Zoned Temperature Control: Helps minimize internal stress through targeted heating and cooling.

- Mold Polishing: High-gloss polishing reduces friction.

- Specialized Release Agents: Use PETG-compatible formulas to prevent chemical reactions.

- Optimized Cooling Channels: Ensure even cooling and prevent localized sticking.

😊 The essence of PETG demolding is balancing temperature and surface control

How to reduce breakage risk during PLA demolding?

Due to its high brittleness, PLA is prone to edge cracking or deformation during demolding if temperature or force control is improper. Low-temperature demolding combined with flexible ejection systems effectively protects product integrity. Mold venting design also affects the smoothness of the molded surface.

- Low-Temperature Rapid Cooling: Reduces stretching stress from thermal expansion.

- Flexible Ejector Pins: Prevent stress concentration leading to cracks.

- Precision Venting Grooves: Minimize defects caused by trapped gases.

- Material Dryness Control: Keep PLA dry to reduce brittleness.

🔍 PLA demolding requires gentle yet precise mechanical and thermal control

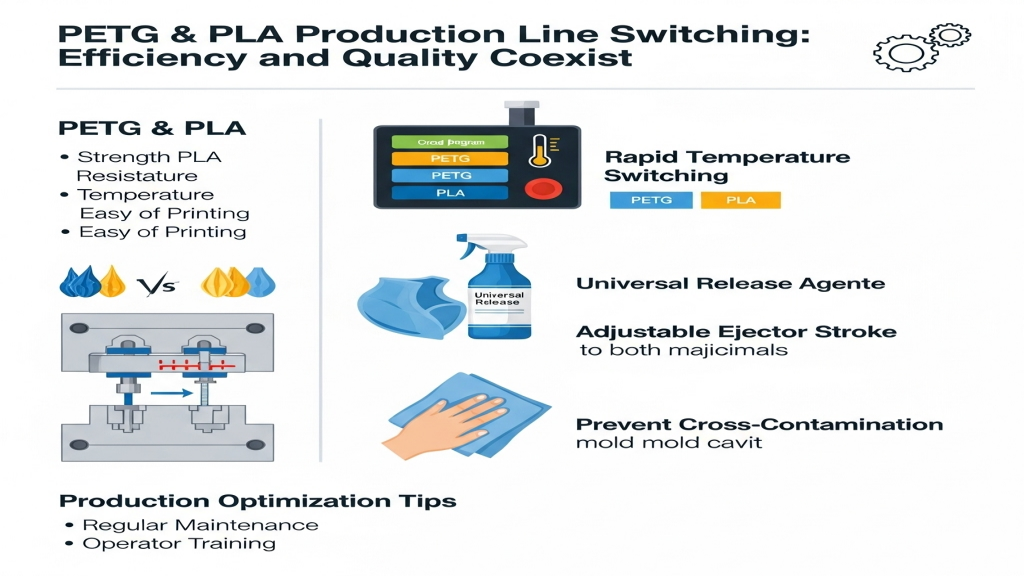

How to switch between PETG and PLA demolding processes on the same production line?

Switching between PETG and PLA on the same production line requires considering differences in temperature, cooling rate, and surface friction. Quickly changing mold temperature settings and release agent formulas ensures smooth transitions while maintaining stable product quality. Proper scheduling also minimizes downtime.

- Rapid Mold Temperature Switching: Pre-set temperature programs to reduce idle time.

- Universal Release Agents: Lower changeover frequency and inventory costs.

- Adjustable Ejector Stroke: Adapt to varying ejection force requirements.

- Cross-Contamination Prevention: Clean molds to avoid residue issues.

⚙️ The core of same-line switching lies in fast adaptation of temperature and formulas

PETG vs. PLA Demolding Performance Comparison

| Performance Metric | PETG Performance | PLA Performance | Adjustment Difficulty | Release Agent Dependency |

|---|---|---|---|---|

| Temperature Sensitivity | Medium | High | Medium | High |

| Surface Finish Requirement | High | Medium | Medium | Medium |

| Cooling Time | Long | Short | High | Medium |

| Breakage Risk | Low | High | Medium | High |

Process Adaptation Strategies

The adaptation strategy for PETG and PLA demolding affects not only production stability but also mold lifespan and product yield. By developing differentiated temperature, cooling, and surface treatment plans, defect rates can be effectively reduced. In commercial production, flexible process switching is a competitive advantage.

1.Optimized Temperature Profiles: Ensure ideal molding conditions for each material.

2.Precise Cooling Time Control: Avoid residual stress affecting demolding.

3.Improved Surface Coatings: Extend mold life and enhance surface quality.

4.Pre-Set Equipment Parameters: Enable fast changeovers with minimal downtime.

Conclusion

The differences in demolding requirements between PETG and PLA mean that production planning must be based on material characteristics. Flexible adjustments in temperature, cooling, and release agent selection allow consistent high-quality output in multi-material production. The ultimate goal is to optimize processes and mold design to achieve both capacity and quality targets.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!