What is Tackling Shrinkage

In the injection molding process, shrinkage refers to the phenomenon where the volume of plastic products decreases due to changes in material density during cooling and solidification. Shrinkage is a common issue in injection molding, primarily affecting the dimensional accuracy and surface quality of the product.

The Impact of Shrinkage

1.Dimensional Changes: Shrinkage causes the actual dimensions of the product to deviate from the design specifications, affecting assembly and usage.

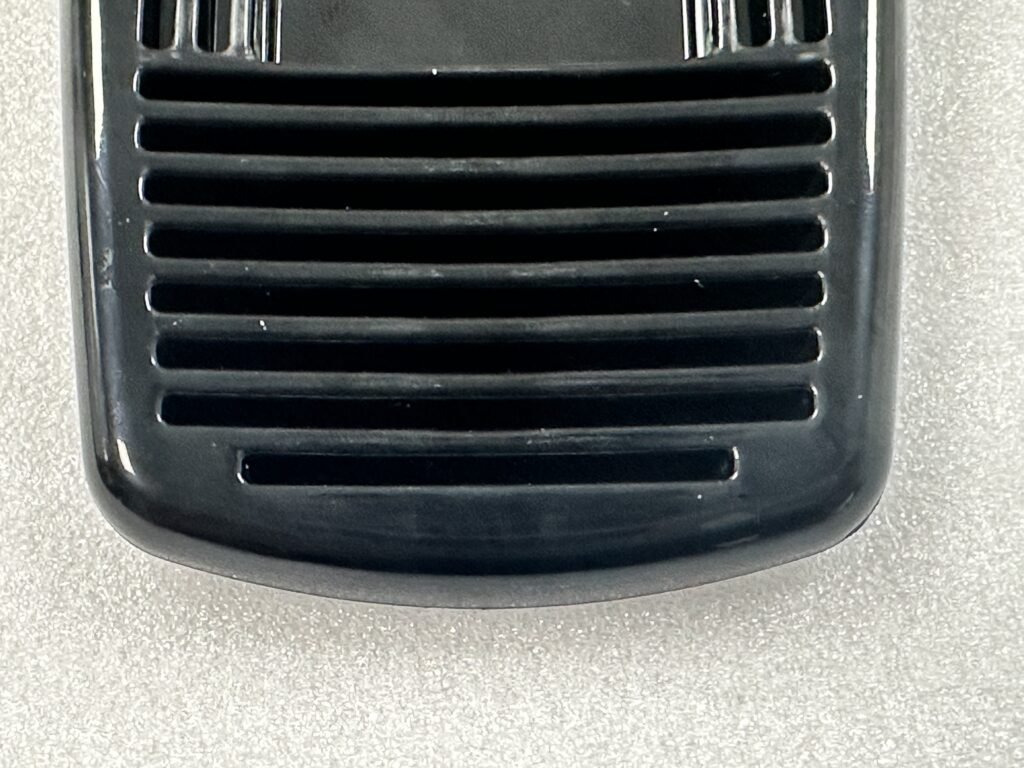

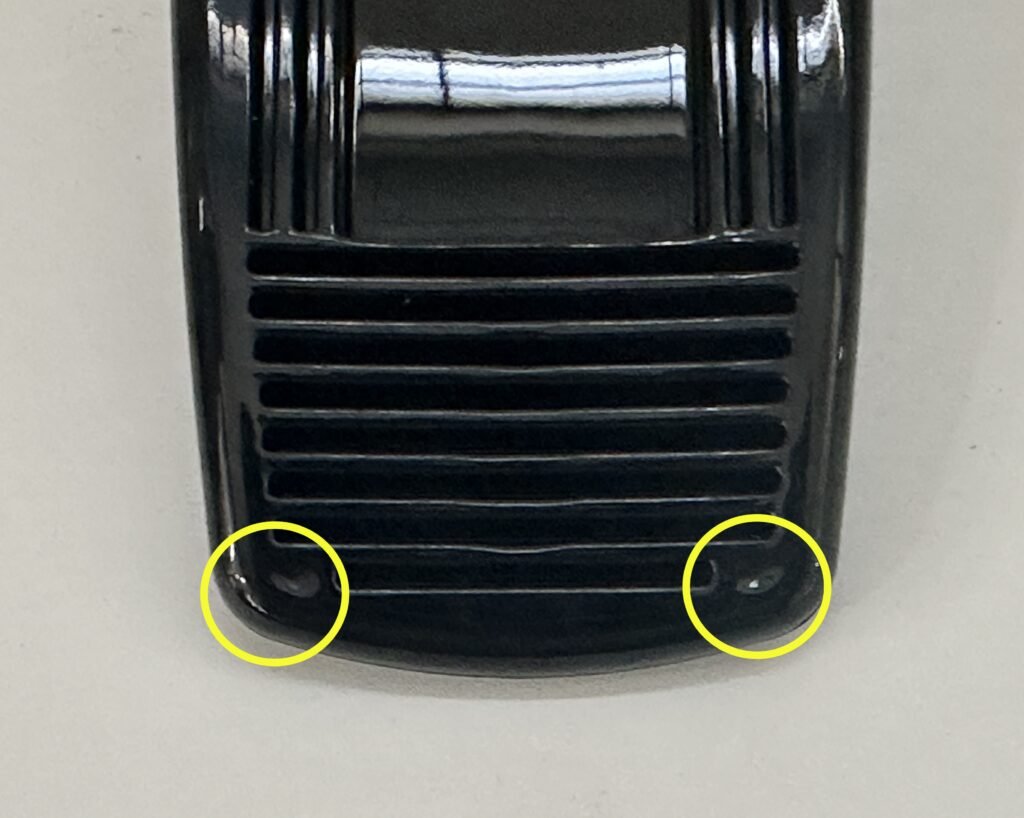

2.Surface Defects: It may lead to the formation of dents, ripples, or other irregularities on the product surface, impacting aesthetic quality.

3.Mechanical Properties: Shrinkage can affect the mechanical properties of the product, such as strength and rigidity.

Causes of Shrinkage

Material Properties: Different plastic materials have varying shrinkage rates. For example, thermoplastics like PP and PE have relatively high shrinkage rates, while engineering plastics like ABS and PC have lower shrinkage rates.

Mold Design: Inadequate mold design, such as an incomplete cooling system or a mismatch between mold cavity size and product design, can lead to shrinkage issues.

Processing Parameters: Injection molding process parameters, such as injection pressure, injection speed, cooling time, and mold temperature, significantly affect shrinkage.

Solution

To address shrinkage issues in the injection molding process, we have implemented a series of comprehensive measures.

First, we carefully select appropriate plastic materials, prioritizing those with lower shrinkage rates, or modify materials to reduce shrinkage. At the same time, we optimize mold design to ensure the cooling system provides even cooling, and set the mold cavity size to account for the material's shrinkage characteristics.

To further minimize shrinkage, we determine the optimal injection molding process parameters through experimentation, including adjusting injection pressure, extending cooling time, and modifying mold temperature.

By combining these measures, we effectively control and reduce shrinkage in molded products, enhancing dimensional accuracy and surface quality. With this systematic approach, Ruicheng not only overcomes shrinkage challenges but also ensures the delivery of high-quality plastic products to our clients.