Material Flow Issue Case Study

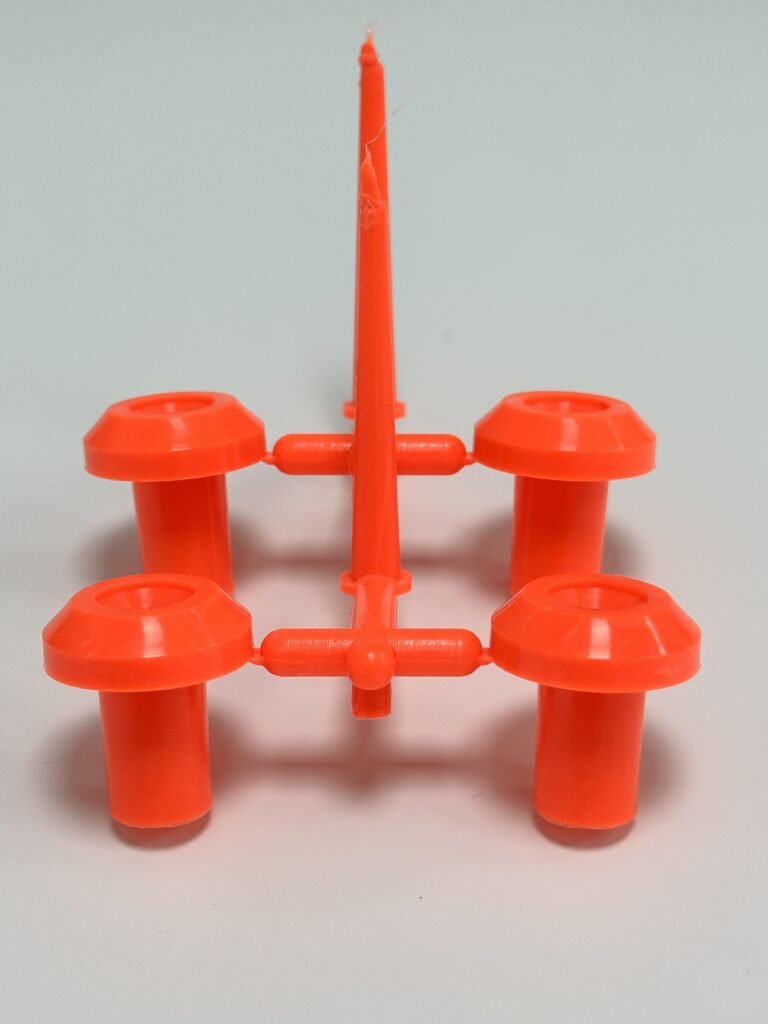

In the injection molding process, material flow marks are a common surface defect, typically manifested as streaks or irregular patterns on the surface of the product, impacting its appearance quality. Below is a case study where we resolved the material flow issue, demonstrating our professional techniques and solutions.

Project Background

One of our clients, a large home appliance manufacturer, was producing a new type of plastic casing. However, during the trial production phase, they discovered noticeable flow marks on the product surface. This issue severely affected the product's appearance, and the client hoped we could quickly identify and resolve the problem.

Problem Analysis

To identify the cause of the flow marks, our engineering team conducted a detailed analysis and testing. By thoroughly inspecting the production process, we identified several possible causes:

Raw Material Issues: Impurities or uneven mixing in the plastic pellets used could lead to the formation of flow marks.

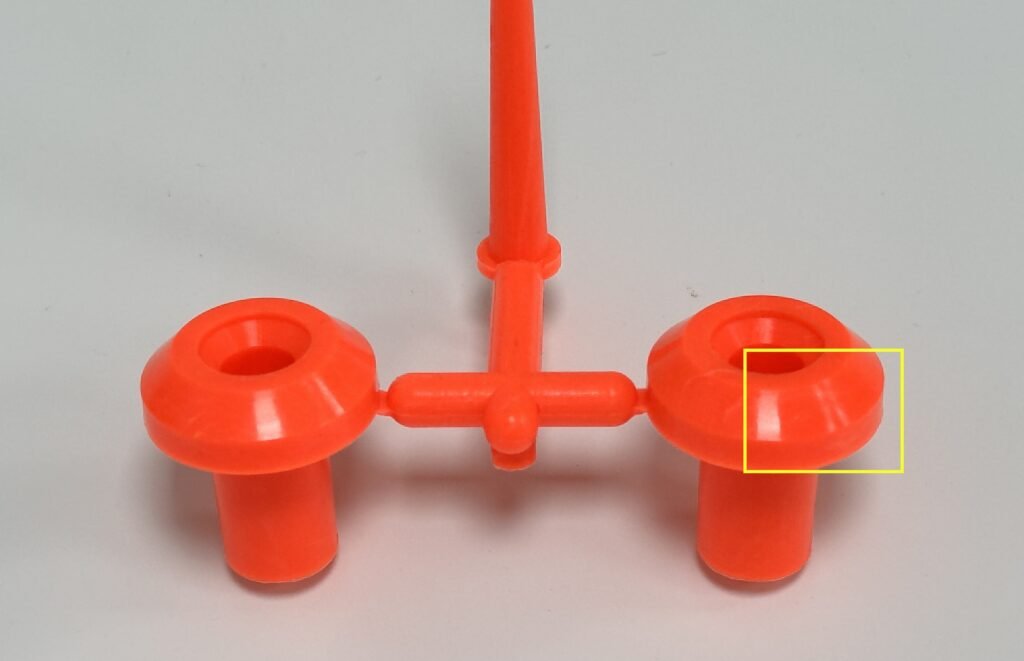

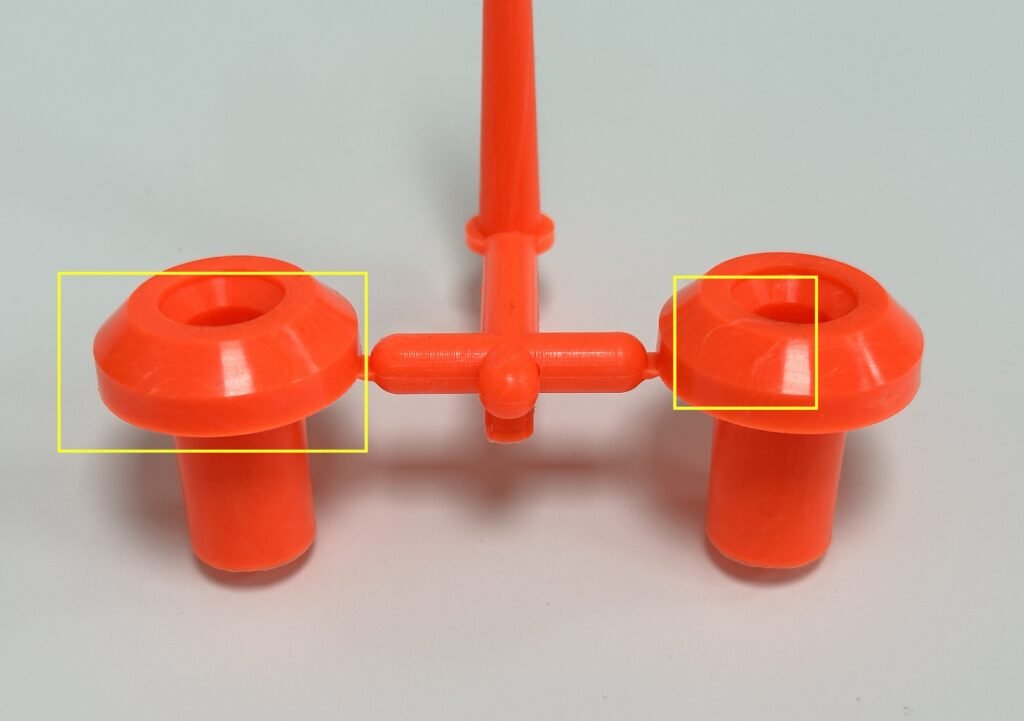

Mold Design: An uneven mold surface or an improperly designed flow channel could affect the flow of molten plastic, resulting in flow marks.

Injection Parameters: Improper settings for injection pressure, speed, and temperature could also cause flow mark issues.

Solution

Based on the analysis results, we implemented the following measures to resolve the flow mark issue:

Material Replacement: We recommended the client use high-purity, impurity-free plastic pellets, ensuring the materials were fully mixed and dried before use.

Mold Design Optimization: Our mold design team polished the mold surface and redesigned the flow channel to ensure smooth flow of the molten plastic within the mold.

Injection Parameter Adjustment: Through a series of experiments, we identified the optimal combination of injection parameters, including appropriately reducing injection pressure and speed, and optimizing melt and mold temperatures.

Result Verification

After these adjustments, the client's new plastic casing successfully eliminated the flow mark issue during trial production. The product surface became smooth and flawless, meeting the client's high standards. The client expressed high satisfaction with our rapid response and professional solution, further strengthening our collaborative relationship.

Conclusion

Flow marks are a common surface defect in injection molding, but through proper analysis and systematic solutions, this issue can be effectively resolved. At Ruicheng, with our extensive experience and advanced technology, we can help clients quickly diagnose and resolve various injection molding issues, ensuring high quality and aesthetic appeal of the products.

If you encounter similar issues in the injection molding process or have any technical needs, please feel free to contact us. We are dedicated to providing you with the best service and solutions.