Introduction

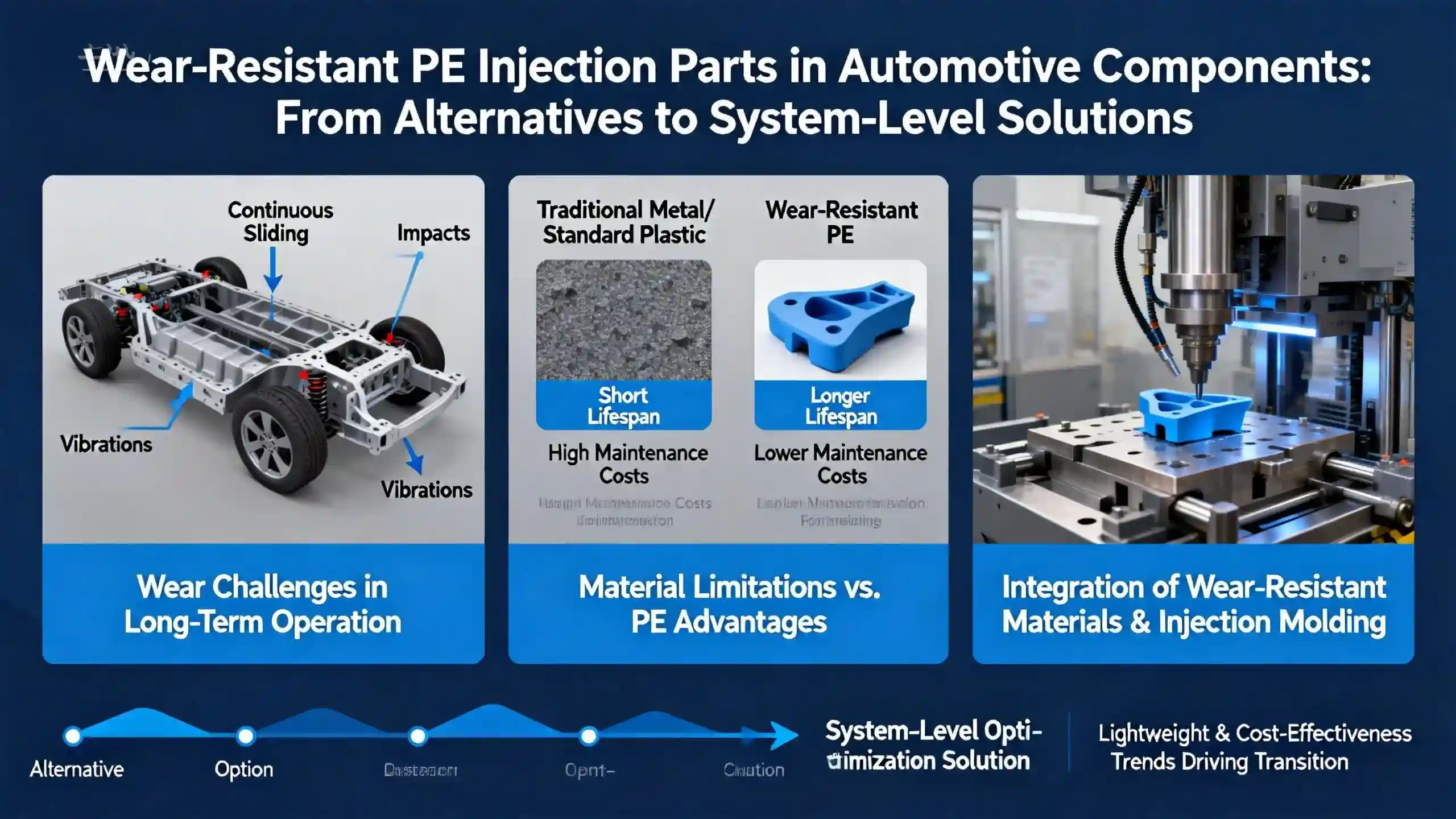

During long-term vehicle operation, continuous sliding, impact, and vibration gradually amplify wear on key components, while traditional metal or standard plastic solutions often fall short in service life and maintenance cost control. The integration of wear-resistant materials with injection molding technology is becoming an indispensable pathway in modern automotive component design.

Driven by trends toward lightweight structures and cost efficiency, wear-resistant PE injection molded parts are shifting from being an “alternative option” to a “system-level optimization solution.” Only when material selection and manufacturing capability form a closed loop can the total lifecycle wear cost of automotive components be truly reduced.

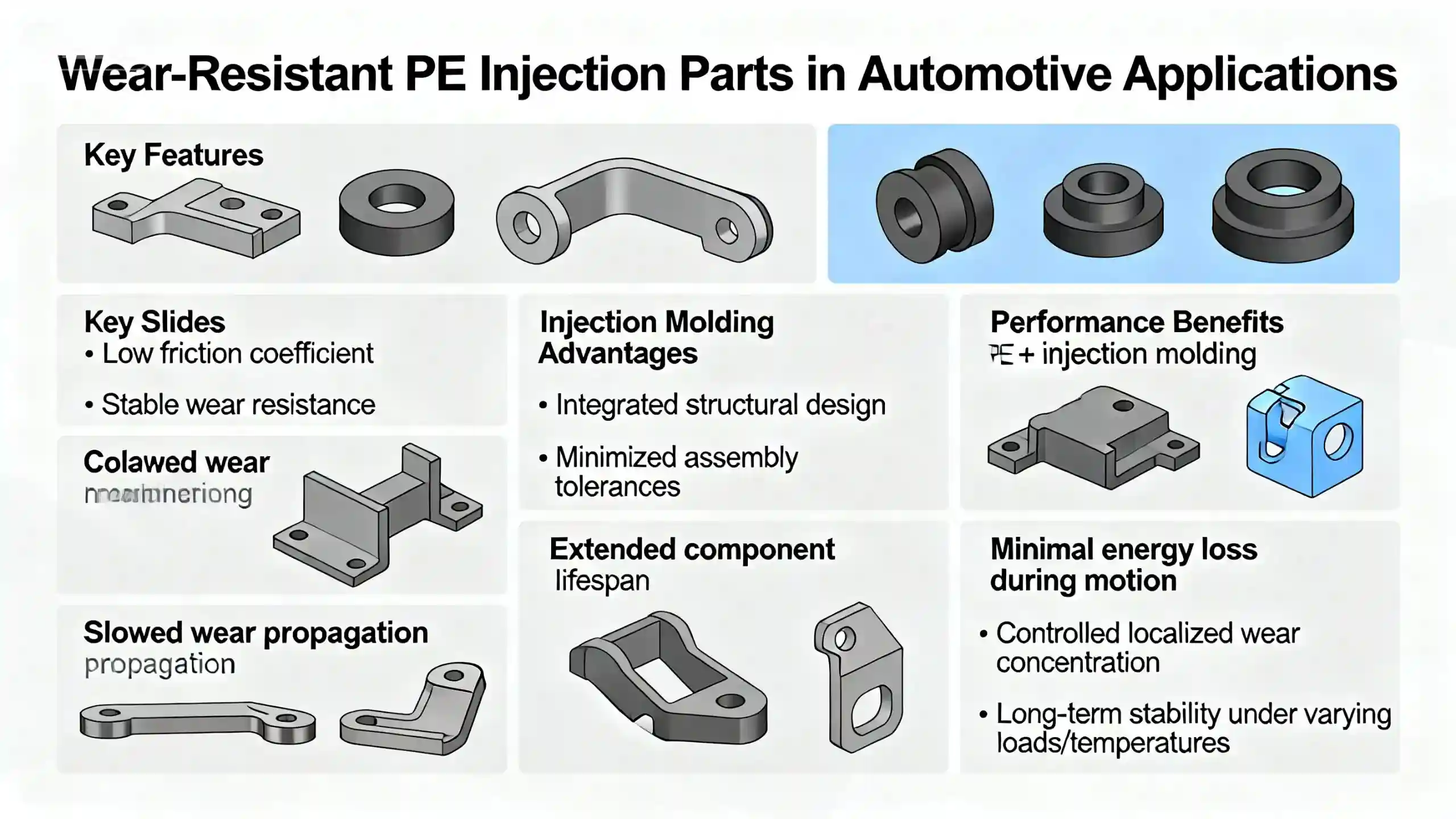

Can wear-resistant PE injection molded parts truly reduce automotive component wear?

In practical applications, wear-resistant PE injection molded parts demonstrate clear advantages in low friction coefficients and stable abrasion resistance, particularly in sliding rails, bushings, and protective components. Injection molding enables integrated structural designs that reduce assembly tolerances while slowing down wear propagation. In automotive applications, the proper use of Polyethylene (PE) combined with Injection molding effectively addresses high-frequency contact and repetitive friction scenarios, significantly extending component service life.

Friction characteristics: Low-friction surfaces continuously reduce energy loss during motion.

Integrated structures: Injection molding minimizes joints and interfaces, helping control localized wear concentration.

Long-term stability: Wear-resistant PE maintains consistent performance under varying loads and temperatures.

Automotive suitability: It offers excellent cost-performance balance in non-load-bearing yet high-wear positions.

🚗 Wear-resistant PE injection molded parts help automotive components achieve more controllable and predictable wear management.

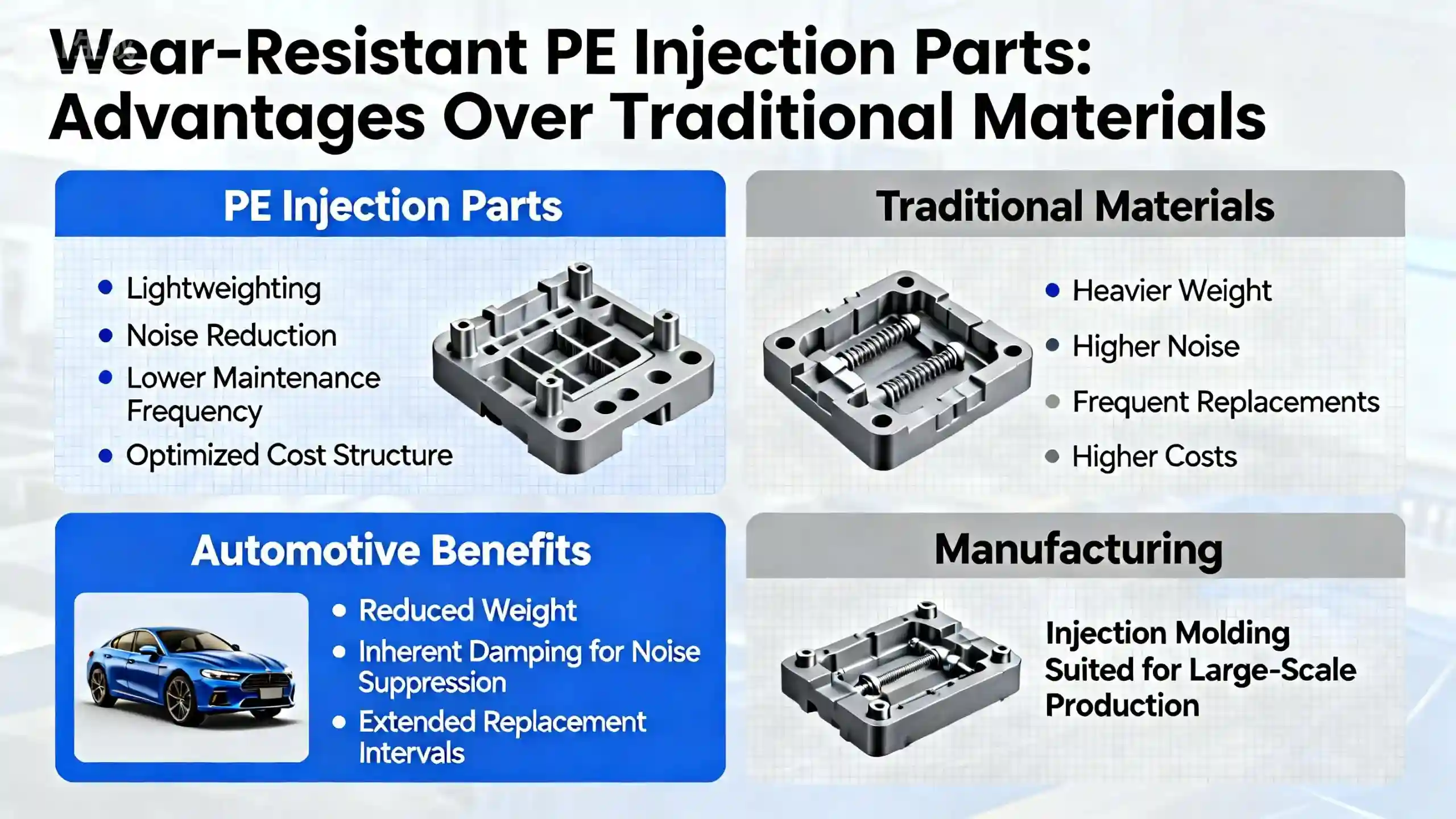

Where do wear-resistant PE injection solutions truly outperform traditional materials?

Compared with metals or conventional engineering plastics, wear-resistant PE injection molded parts offer a more balanced performance profile in automotive applications. Their advantage lies not in a single wear index, but in system-level benefits such as weight reduction, noise control, and extended maintenance cycles. In real projects, replacing traditional solutions with wear-resistant plastics often results in lower total lifecycle costs for automotive components.

Lightweight contribution: Significantly reduces vehicle weight compared with metal solutions.

Noise reduction: Inherent damping properties help minimize operational noise.

Reduced maintenance frequency: Enhanced wear resistance extends replacement intervals and reduces downtime.

Optimized cost structure: After mold investment, injection molding is more suitable for scalable production.

⚙️ The value of wear-resistant PE injection solutions is reflected in long-term system benefits rather than isolated performance metrics.

How can procurement avoid selection risks when choosing wear-resistant PE injection molded parts?

In automotive procurement decisions, focusing solely on material labels often fails to prevent downstream risks. The reliability of wear-resistant PE injection molded parts depends more on formulation control, mold design, and manufacturing expertise than on nominal material grades. By partnering with experienced injection molding manufacturers and referencing abrasion testing and quality management systems, buyers can significantly reduce mismatches between selection and real-world performance.

Formulation consistency: Stable raw material sourcing ensures batch-to-batch performance consistency.

Mold compatibility: Proper runner and cooling designs reduce internal stress.

Verification processes: Sample testing and condition simulation reveal potential issues early.

Manufacturing synergy: Experienced suppliers better understand real automotive usage scenarios.

🛠️ A correct selection strategy is more critical than simply pursuing higher wear resistance values.

Comparative value of wear-resistant PE injection molded parts in automotive applications

| Comparison Dimension | Wear-resistant PE Injection Parts | Standard Plastic Parts | Metal Parts | Composite Materials |

|---|---|---|---|---|

| Wear performance | Stable and controllable | Easily degrades | High but lubrication-dependent | Inconsistent |

| Weight | Light | Light | Heavy | Medium |

| Noise control | Excellent | Average | Poor | Average |

| Maintenance cost | Low | Medium | High | Medium |

Want to evaluate which solution best fits your vehicle platform and operating conditions? Feel free to contact us for tailored recommendations.

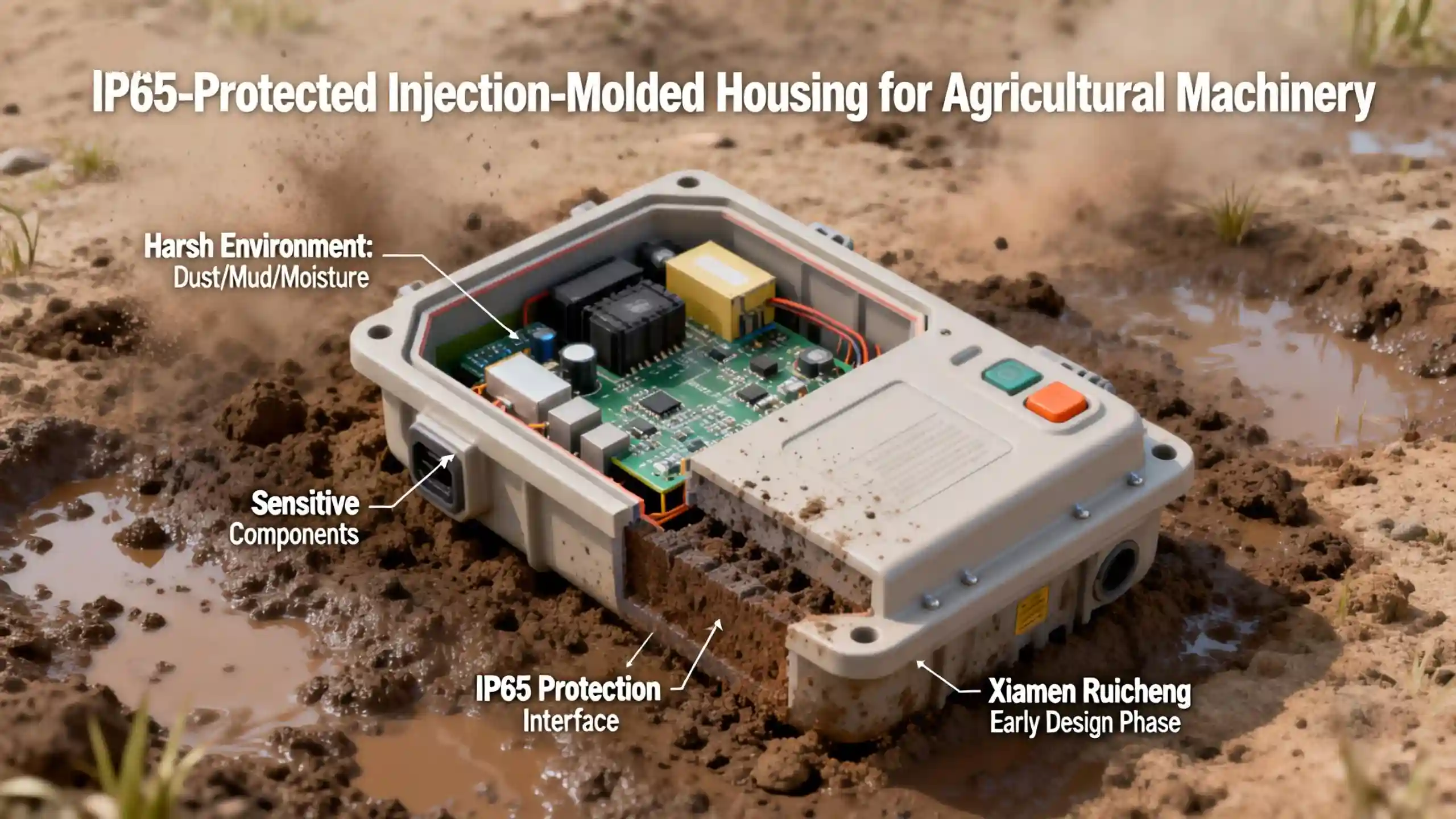

The critical path from material selection to mass production

Introducing wear-resistant PE injection molded parts into automotive projects is not merely a material replacement, but a systematic optimization from design to mass production. Only when material performance, mold development, and production capacity form a closed-loop process can the commercial value of wear-resistant solutions be fully realized. Xiamen Ruicheng supports automotive customers through upfront evaluation, sample validation, and scalable production, reducing trial-and-error costs while accelerating decision-making.

1.Preliminary evaluation: Analyze operating conditions to define wear grades and structural concepts.

2.Sample validation: Verify real wear performance through pilot injection runs.

3.Mass production planning: Align molds and capacity with long-term demand.

4.Ongoing support: Provide continuous process and material optimization throughout the project lifecycle.

Frequently Asked Questions (FAQ)

Question 1: What are the core advantages of your wear-resistant PE injection molded parts?

Answer: We define wear targets and structural requirements based on real application scenarios, supported by stable material systems and process control to ensure consistent in-use performance that meets buyers’ durability expectations.

Question 2: What information is required to initiate a procurement inquiry?

Answer: Basic drawings, operating condition descriptions, and estimated purchase volumes help us quickly evaluate feasibility and provide quotations with process recommendations through dedicated communication channels.

Question 3: How do delivery terms vary by purchase volume?

Answer: Different MOQ and lead-time structures are applied for pilot runs versus mass production, supported by flexible capacity planning to ensure stable delivery aligned with project schedules.

Question 4: How are quality or delivery issues handled after purchase?

Answer: Clear evaluation criteria and response workflows enable timely reinspection, adjustment, or replacement within agreed timelines, supported by defined quality assurance commitments.

Question 5: Can you provide customization for special operating conditions?

Answer: Yes, formulations and structural designs can be adapted based on specific environments. Detailed operating data is required, with customization timelines and cost impacts clarified during the proposal stage.

Conclusion

Wear-resistant PE injection molded parts represent more than a material substitution in automotive applications; they are a system-level solution focused on durability, cost control, and reliability. Through informed selection and experienced manufacturing support, companies can reduce wear-related losses while improving overall project certainty. When procurement decisions shift from parameter comparison to full lifecycle value assessment, the true advantages of wear-resistant injection solutions become evident.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!