Rapid prototyping technology is advancing quickly, providing new possibilities for high-performance materials. The demand for processing PEEK and other specialty plastics is increasing, posing higher requirements for material suppliers and manufacturers. By optimizing process parameters, high-precision manufacturing of complex structures can be achieved, improving product development efficiency and market responsiveness.

At the same time, rapid prototyping is no longer limited to lab models and is increasingly applied to functional verification parts and small-batch production. The high heat resistance and mechanical performance of specialty plastics make them widely used in aerospace, medical devices, and industrial components. Proper process design and material selection are key to ensuring final product performance.

Can rapid prototyping process PEEK?

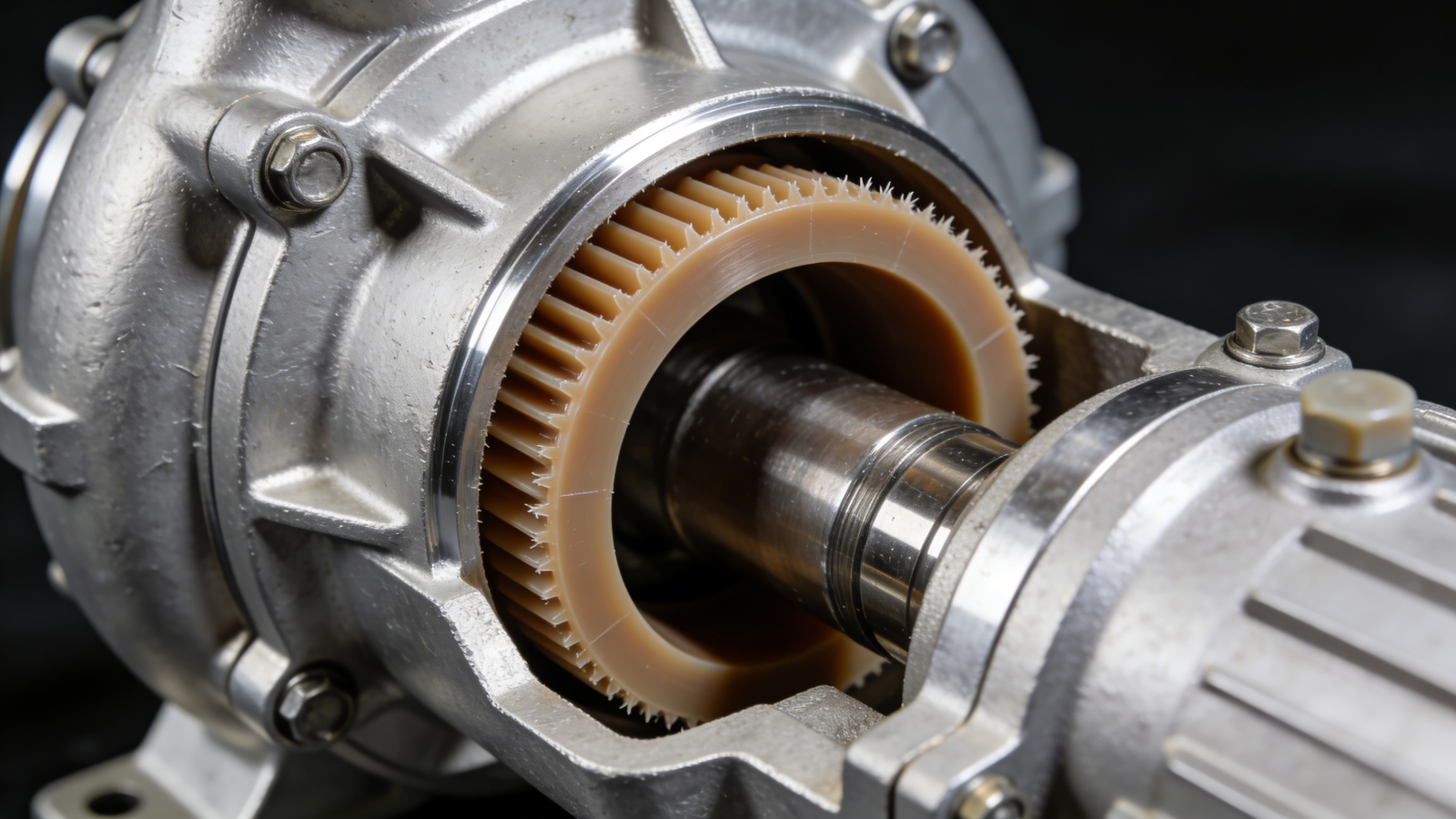

When prototyping PEEK, the material's high melting point and thermal stability must be considered. Controlling temperature and extrusion speed is key to ensuring part accuracy. Additionally, fixture design and cooling strategy significantly affect dimensional stability. With precise process parameters, PEEK parts can meet functional verification and performance testing requirements.

Material Compatibility: PEEK and Rapid PrototypingPEEK can be processed in rapid prototyping with specific techniques.

Temperature Control: High-temperature extrusion equipment ensures material stability during processing.

Dimensional Accuracy: Precision Fixture DesignFixtures ensure accuracy for complex parts.

Production Efficiency: Optimized process parameters can shorten prototyping time.

🛠 Rapid prototyping can meet functional verification requirements for PEEK parts.

Are other specialty plastics feasible?

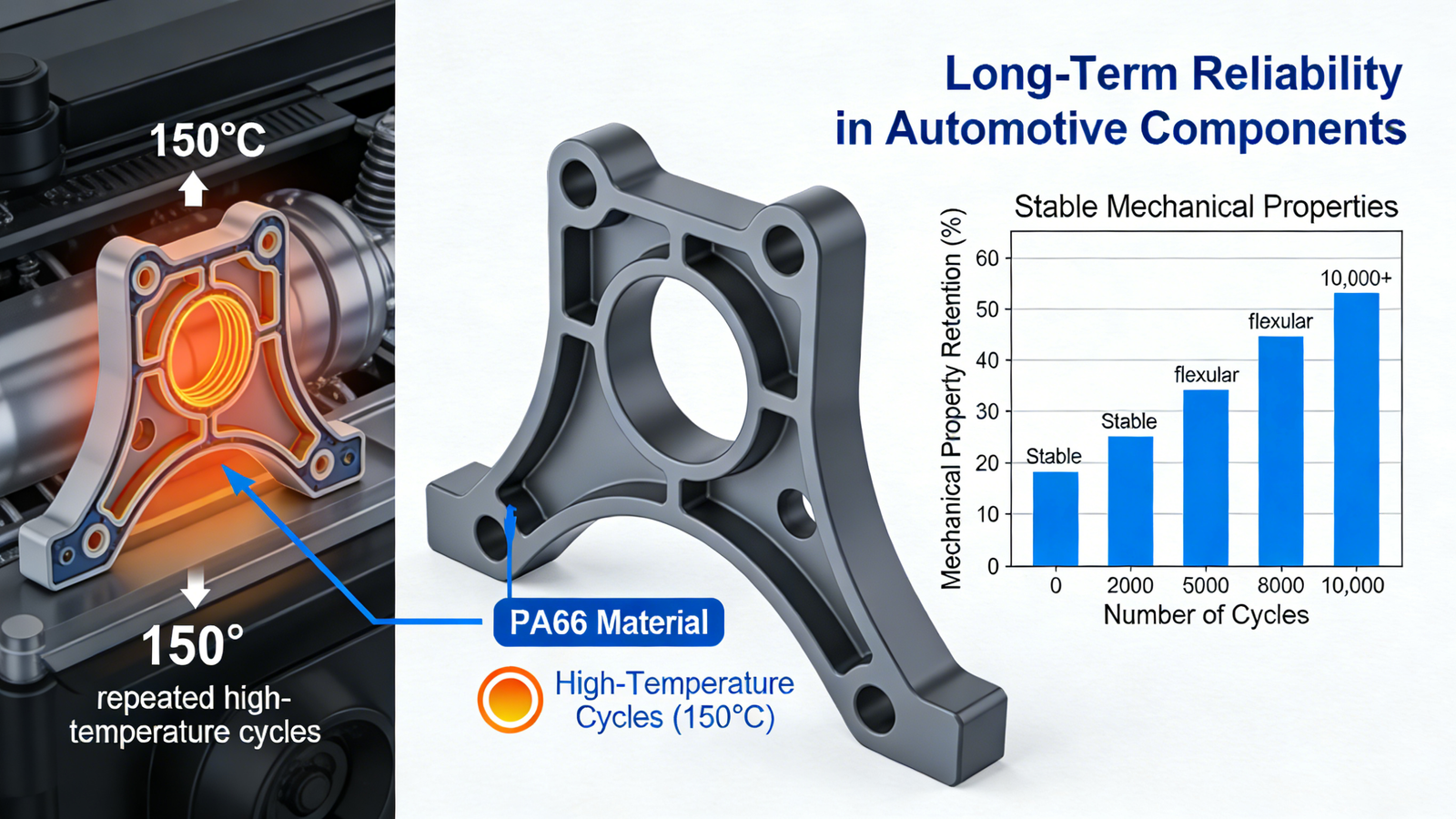

Besides PEEK, rapid prototyping can handle high-performance engineering plastics like PPS and PEI. The heat deflection temperature and mechanical strength of these materials determine process feasibility. Material and process combinations should consider part complexity and functional requirements. Customized extrusion parameters can ensure part performance and surface quality.

Material Selection: High-Performance Plastics ListSuitable specialty plastics for rapid prototyping.

Process Optimization: Controlling temperature and speed improves part quality.

Structural Adaptation: Complex Structure DesignEnsures reliability of specialty plastic parts.

Functional Verification: Guarantees that finished parts meet usage conditions.

🔧 Rapid prototyping is also suitable for processing various specialty plastic parts.

Is rapid prototyping suitable for small-batch production?

Rapid prototyping can directly support small-batch production, especially for complex or customized parts. Reducing mold development time allows rapid response to market and customer demands. Combined with precision machining and quality control, high-quality delivery of small-batch parts is achievable. This approach is particularly effective for functional verification and limited-supply parts.

Quick Response: Small-Batch Production Strategy : Accelerates product launch cycles.

Customized Processing: Supports production of parts with special materials and structures.

Quality Assurance: Process monitoring and inspection ensure reliability.

Cost Control: Reduces mold and inventory expenses.

📦 Rapid prototyping is an ideal solution for small-batch customized production.

Comparison of Rapid Prototyping Suitability for Different Plastics

| Material | Processing Difficulty | Thermal Stability | Mechanical Performance | Surface Quality | Recommended Use |

|---|---|---|---|---|---|

| PEEK | High | High | High | Excellent | Aerospace, Medical, Industrial Components |

| PEI | Medium | Medium-High | High | Good | Functional Verification, Small-Batch Parts |

| PPS | Medium | High | Medium-High | Good | Engineering Prototypes, Small-Batch Production |

| Ultem | Medium | High | High | Excellent | Functional Verification, High-Temperature Applications |

💡 To learn more about material adaptation solutions, click contact us for a custom consultation.

Expansion

Rapid prototyping is not just a design verification tool; it can extend to functional testing and small-batch production. Proper material and process selection can significantly shorten development cycles, reduce cost waste, and improve market responsiveness. By integrating CAD/CAE technology with advanced equipment, parts can transition seamlessly from design to delivery.

1.Functional Verification: Ensure parts meet design requirements.

2.Process Integration: Use CAE analysis to optimize part molding.

3.Batch Scaling: Transition from prototype to small-batch production.

4.Cost Control: Reduce mold development and material waste.

FAQ

Question 1: What are the core quality standards for rapid prototyping PEEK?

Answer: Key dimensional tolerance ±0.02mm, with high-temperature extrusion + CMM inspection, full-process quality control ensures mechanical performance.

Question 2: How to connect with rapid prototyping suppliers and get quotes?

Answer: Submit CAD/STEP drawings; receive DFM assessment and quote within 24 hours, with free sample confirmation support.

Question 3: What are the MOQ and delivery lead time for rapid prototyping PEEK and specialty plastics?

Answer: Small-batch MOQ starts at 50 pcs, batch production available; prototyping 3-5 days, batch 7-12 days, rush orders can be expedited.

Conclusion

Rapid prototyping technology is increasingly expanding into high-performance plastics, and PEEK and other specialty plastics can achieve high-precision processing through optimized processes. This approach is suitable for both functional verification and small-batch production, significantly improving R&D efficiency and market responsiveness. With professional techniques and process management, part performance and delivery quality can be reliably ensured.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!