Introduction

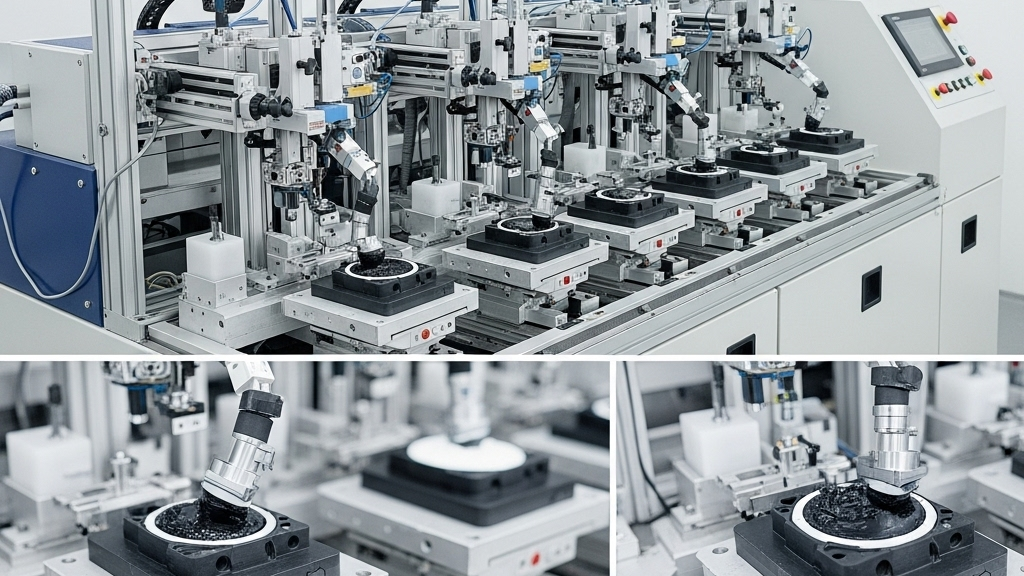

Pad printing has evolved beyond traditional decorative applications and is now being used for functional coating on injection molded parts. It has become a cost-effective and flexible method for surface treatment in industries like automotive, electronics, and medical devices.Its flexibility makes it ideal for diversified, small-batch production.

In achieving properties such as anti-static, UV resistance, and conductivity, pad printing offers precise multilocation coating and controlled thickness. This method provides an alternative to spraying and allows for more freedom in product design. Especially for complex 3D surfaces, pad printing holds a natural advantage.

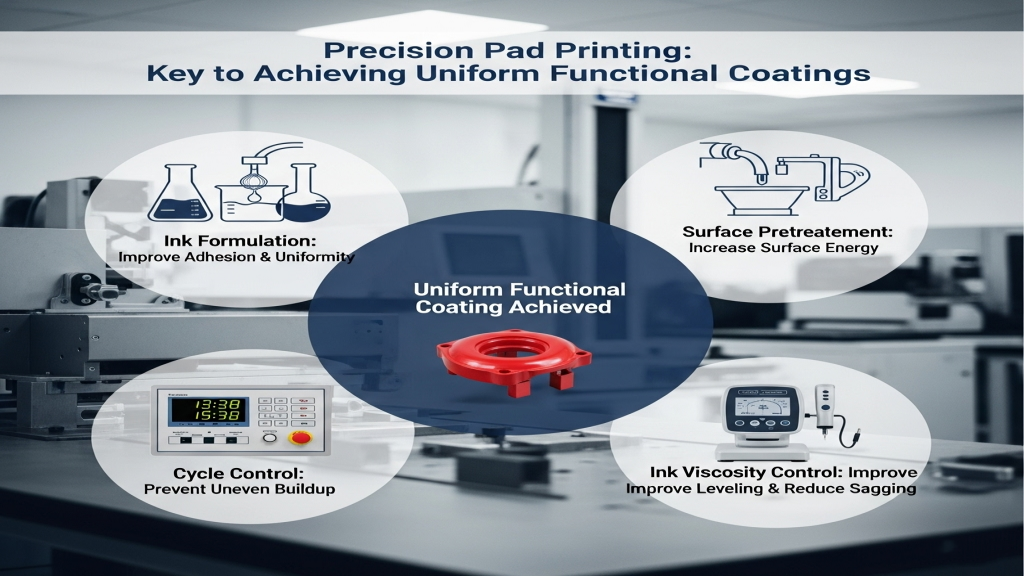

Can Pad Printing Deliver Uniform Functional Coatings?

Functional coatings require a high level of uniformity, and the efficiency of ink transfer in pad printing depends heavily on pad hardness and cliché structure. By optimizing pad hardness and ink viscosity, functional coatings can be applied with good consistency. Additives or special inks can further enhance distribution.

- Ink formulation techniques: Proper ratios improve adhesion and uniformity.

- Surface pretreatment: Increases surface energy for better coating.

- Cycle control in printing: Prevents uneven buildup.

- Ink viscosity control: Improves leveling and reduces sagging.

🎯 With process tuning, pad printing can meet uniformity demands for many functional coatings.

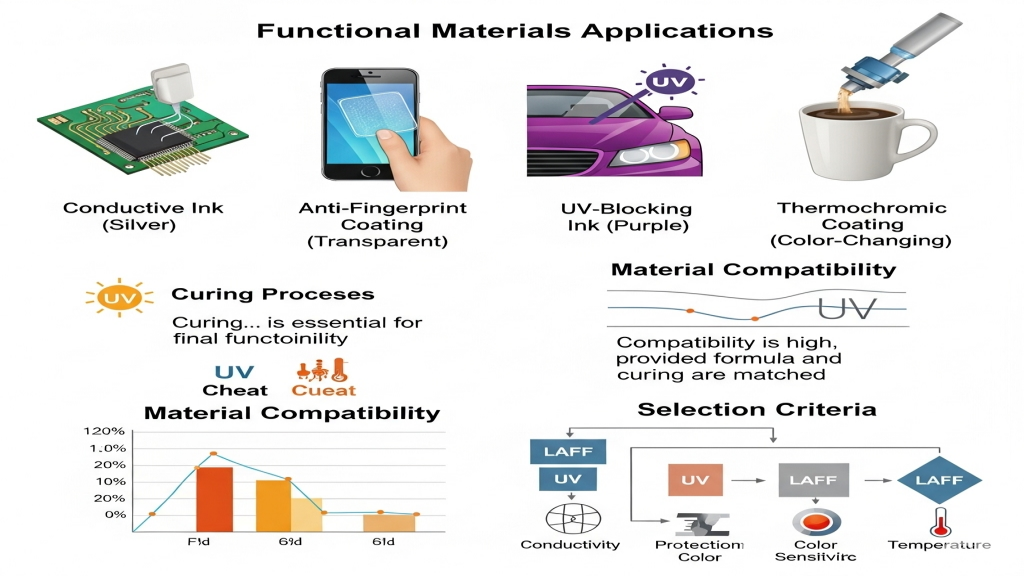

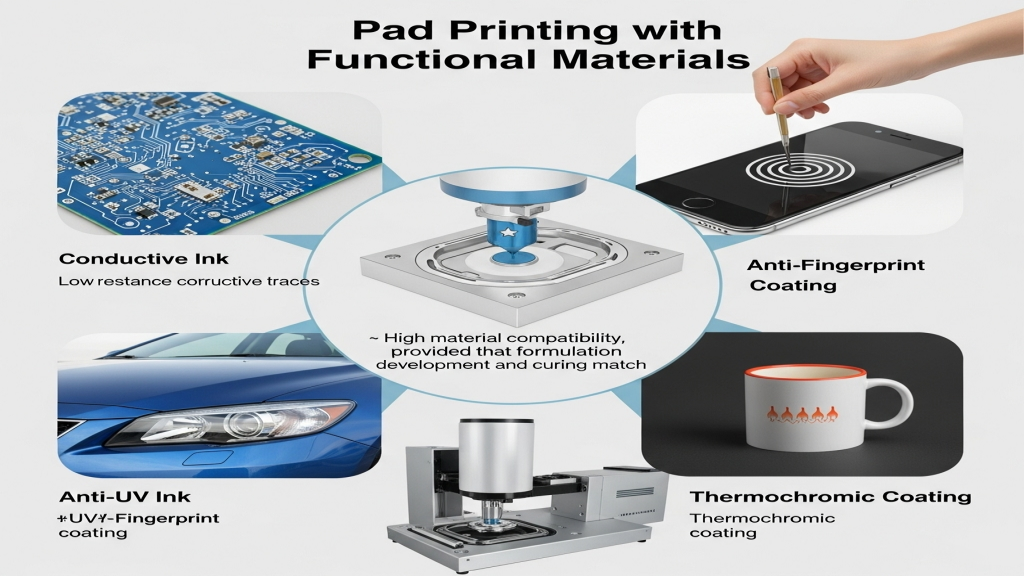

What Types of Functional Materials Are Suitable for Pad Printing?

Not all functional coatings are suitable for pad printing, but UV-resistant, conductive, and water-based flame-retardant inks are proven options. The key is whether the ink system supports both transfer and curing while maintaining desired properties. Curing via UV or heat is essential for final functionality.

- Conductive inks: Ideal for low-resistance trace printing.

- Anti-fingerprint coatings: Used on consumer electronics surfaces.

- UV-blocking inks: Suitable for automotive lights and housings.

- Thermochromic coatings: Enable temperature-sensitive surface reactions.

🧪 Material compatibility is high, provided formula development and curing are matched.

How to Ensure Strong Adhesion of Pad-Printed Coatings?

Adhesion strength is critical for successful functional pad printing. Treatments such as corona, flame, or plasma are commonly used to increase surface energy and improve adhesion. Ink selection tailored to the plastic substrate also plays a crucial role. For crystalline or low-polarity plastics, primers or adhesion promoters are necessary.

- Plasma surface treatment: Boosts surface activation for bonding.

- Primer systems: Acts as an intermediary layer.

- Surface cleaning: Removes mold release agents and dust.

- Ink crosslinking additives: Strengthens physical bonding.

🧷 Adhesion is best achieved through synergy of pre-, mid-, and post-processing.

Functional Pad Printing vs Other Coating Methods

| Feature / Method | Pad Printing | Screen Printing | Spraying | Dipping |

|---|---|---|---|---|

| Complex Surface Handling | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | ★☆☆☆☆ |

| Coating Thickness Control | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ |

| Functional Ink Support | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| 3D Surface Compatibility | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | ★☆☆☆☆ |

| Small Batch Efficiency | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | ★★☆☆☆ |

Which Industries Benefit Most from Functional Pad Printing?

Functional pad printing is widely adopted in automotive electronics, smart devices, and medical plastics where advanced surface performance is required. Especially for irregular shapes, precise locations, and multifunctional surfaces, pad printing offers a unique combination of efficiency and performance.

1.Automotive electronics: For scratch resistance, anti-fingerprint, and conductive paths.

2.Smart consumer products: Touch areas, buttons, and printed indicators.

3.Medical equipment: Anti-bacterial, dustproof, and ESD-safe surfaces.

4.Industrial controllers: UV and flame-resistant housing coatings.

Conclusion

Pad printing has evolved from labeling to becoming a technical method for functional surface applications. With optimized materials and process engineering, functional coatings can be precisely and stably applied on injection molded parts. This makes it highly attractive in customized, high-value manufacturing.Pad printing bridges structural design with surface engineering efficiently. As materials and machines evolve, its market potential in injection molding continues to grow.

For expert assistance in implementing functional pad printing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!