Introduction

Nylon materials are widely applied in automotive steering system bushings due to their wear resistance, toughness, and molding flexibility. Xiamen Ruicheng ensures stable performance under complex working conditions through precise injection molding and mold optimization. Structural stability under continuous mechanical stress is a key indicator to evaluate whether the material meets automotive-grade standards. Nylon bushings maintain dimensional and functional consistency across various temperature and humidity environments, satisfying the requirements of multiple vehicle platforms.

Additionally, the lightweight advantage and cost efficiency of nylon make it a preferred choice over some metal bushing solutions. Xiamen Ruicheng enhances batch manufacturing consistency and reliability through material modification, wall thickness optimization, and precise injection parameters. Batch production consistency determines if the material truly meets automotive-grade requirements.

Do nylon bushings have the capability to pass automotive-grade durability tests?

Nylon bushings maintain excellent performance under high-frequency vibration, continuous friction, and temperature fluctuation. Xiamen Ruicheng ensures uniform wall thickness and optimized stress distribution via injection molding, allowing bushings to maintain structural stability under complex working conditions. The crystallinity of the material improves service life through wear-resistant materials, and process compensation at high-load zones reduces fatigue cracking fatigue. Durability performance in full-vehicle environmental simulation is critical for evaluating automotive-grade capability.

Structural stability: Nylon bushings maintain controlled deformation under repeated friction and high-load cycles.

Wear performance: Material preserves surface integrity under dry and lubricated conditions.

Thermal cycling tolerance: Bushings maintain geometric precision during long-term thermal alternation.

Load response: Fatigue life remains stable under localized high-load environments.

🙂 Nylon bushings meet automotive-grade durability standards.

Can nylon bushings satisfy steering system precision and NVH requirements?

Through precision injection molding and mold compensation, Xiamen Ruicheng ensures nylon bushings achieve high repeatable dimensional accuracy. The intrinsic damping properties of the material help reduce NVH in steering systems, and lubrication-optimized structures enhance low-frequency noise control noise and vibration transmission vibration. Precision and NVH performance are core indicators of automotive-grade bushings.

Dimensional accuracy: Mold temperature control and shrinkage compensation ensure stable fit tolerances.

Noise control: Material damping effectively reduces operational noise.

Vibration attenuation: Bushing structure minimizes vibration transmission to the steering wheel.

Steering feedback: Consistent handling feel is maintained for drivers.

🔧 Nylon bushings fully adapt to automotive-grade precision and NVH requirements.

Can nylon materials meet the full lifecycle temperature, chemical, and fatigue requirements?

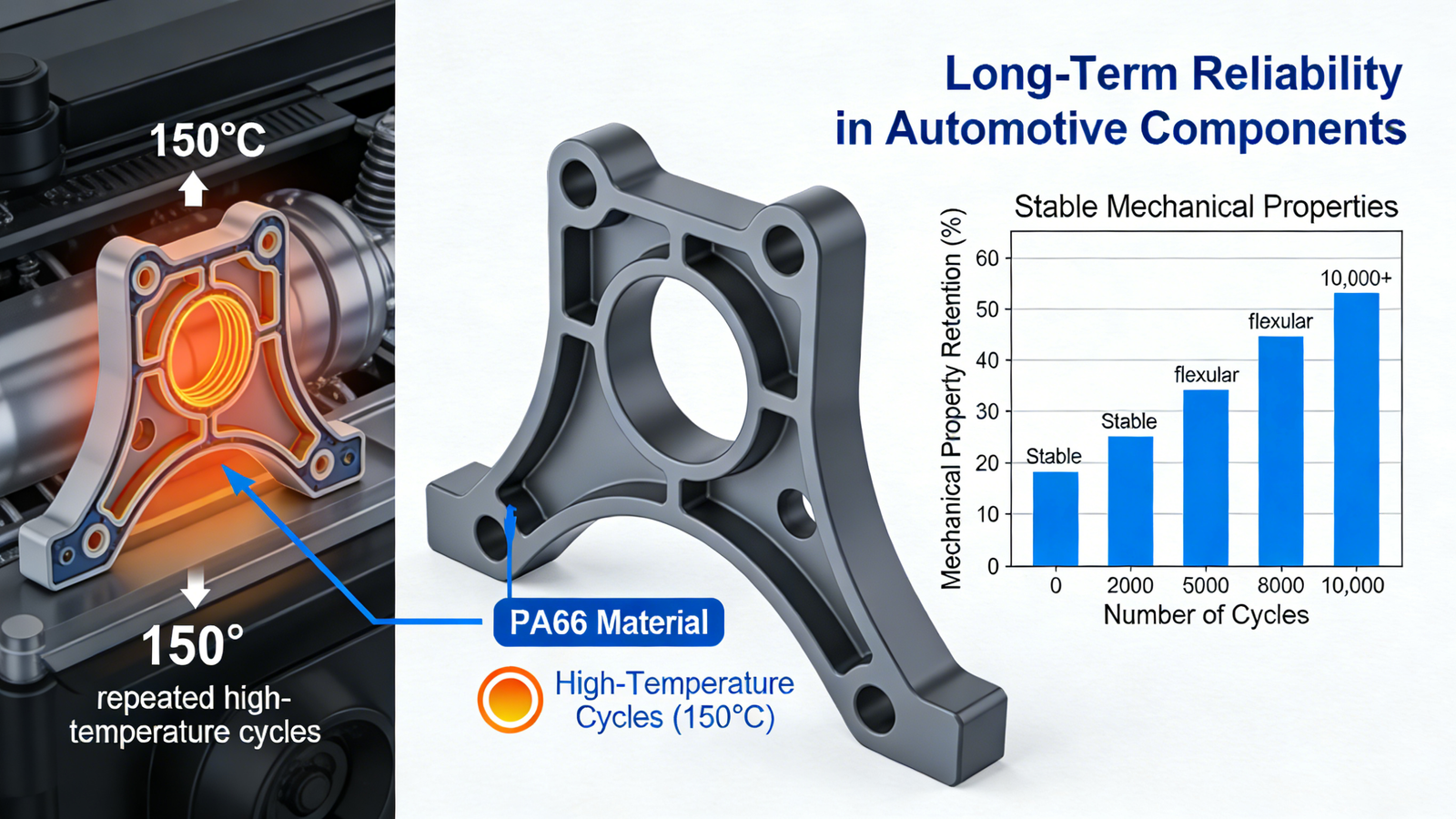

Nylon exhibits high- and low-temperature resistance, and glass fiber reinforcement and anti-aging formulations improve long-term stability. Xiamen Ruicheng designs chemical-resistant bushings to withstand lubricants, cleaning agents, and moisture, while fiber reinforcement ensures fatigue life. Automotive-grade thermal shock, immersion, and load fatigue tests show maintained strength and controlled deformation polyamide aging. Full lifecycle performance determines automotive-grade eligibility.

Thermal stability: Maintains dimension and strength under extreme temperature cycles.

Chemical resistance: Adapts to common vehicle fluid environments.

Fatigue life: No cracks or deformation under long-term stress.

Long-term consistency: Retains fit and surface integrity.

🚗 Nylon bushings demonstrate reliable performance across multi-dimensional aging scenarios.

Nylon Bushing Automotive-Grade Adaptability Comparison Table

| Feature | Nylon Bushing | Metal Bushing | Rubber Bushing | POM Bushing |

|---|---|---|---|---|

| Wear resistance | High | Very High | Medium | High |

| NVH performance | Medium-High | Medium | High | Medium |

| Weight | Very light | Heavy | Medium | Light |

| Cost | Low | Medium-High | Medium | Medium |

| Temperature tolerance | High | Very High | Medium | High |

| Lifetime consistency | High | Very High | Medium | High |

Explore more automotive-grade solutions contact us

Engineering Expansion Applications of Nylon Bushings in Vehicle Platforms

Nylon bushings are favored for multi-vehicle steering systems due to their lightweight and high injection molding repeatability. Xiamen Ruicheng applies material modification, mold optimization, and CAE simulations to predict life performance, enhancing structural stability. Engineering verification determines bushing automotive-grade pass rate and reliability. Bushings can be shared across platforms, reducing development costs and shortening validation cycles.

1.Structural optimization: Reinforcement ribs improve load-bearing capability.

2.Material enhancement: Glass fiber or modifiers improve temperature and fatigue performance.

3.NVH matching: Damping parameters adjusted based on vehicle vibration tests.

4.Life prediction: CAE fatigue and aging simulations guide design.

FAQ

Q1: What is the quality baseline of your nylon bushings?

A: Xiamen Ruicheng provides automotive-grade material certification, ensuring wear, fatigue, and dimensional accuracy meet standards, with batch verification to guarantee long-term consistency, satisfying steering system durability indicators.

Q2: What information is needed to quickly get a quote for nylon bushings?

A: Provide mating part drawings, load conditions, annual demand, and environmental info. Xiamen Ruicheng screens in 2 hours and delivers full process analysis and quote within 12 hours, with sample testing support.

Q3: How do lead times differ for different purchase quantities of nylon bushings?

A: Trial production MOQ is 50 pieces, bulk orders enjoy pricing optimization; standard lead time 7–10 days, peak season flexible production ensures stable delivery, urgent orders can be scheduled within 48 hours.

Q4: What if there are quality or delivery issues after purchasing nylon bushings?

A: 7-day quality recheck, confirmed issues handled with replacement within 48 hours, key parts guaranteed 12–18 months, contract clearly defines responsibilities.

Q5: Can nylon bushings be customized for specific working conditions?

A: Supports customization for temperature, load, and life scenarios, adjusting formulations, structures, surface treatment, and assembly fit, with sample verification and engineering collaboration.

Conclusion

Nylon bushings demonstrate excellent performance in durability, precision, NVH, and full lifecycle, supported by toughness, wear resistance, and injection repeatability. Xiamen Ruicheng ensures bushings meet automotive-grade requirements through material modification and mold optimization. Their lightweight and cost advantages make them a reliable alternative to metal bushings, suitable for multi-platform vehicle applications, reducing development cycles and cost while providing robust decision support for automakers.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!