Introduction

Automotive brackets play a critical role in supporting, positioning, and stabilizing vehicle systems, making material selection a decisive factor for long-term reliability and safety. As lightweighting becomes a core development direction in the automotive industry, glass fiber reinforced PP injection molding has gradually shifted from an “alternative option” to a mainstream engineering solution. When properly designed and processed, glass fiber reinforced PP can meet the load demands of most automotive bracket applications.

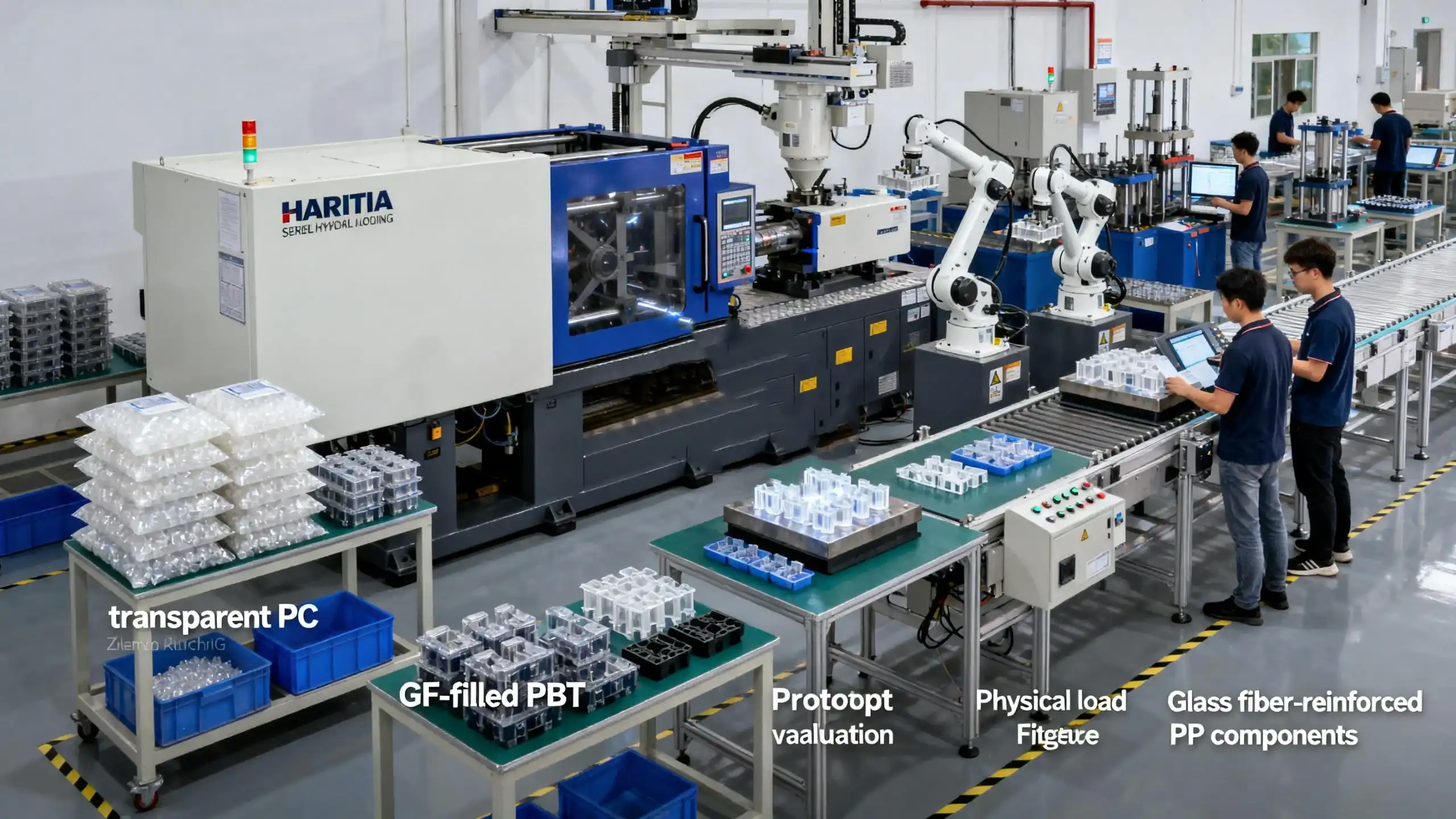

In real purchasing decisions, customers are no longer focused solely on material datasheets, but on how finished parts perform under real operating conditions, how consistent mass production can be, and whether supply risks are controllable. Xiamen Ruicheng translates the inherent advantages of glass fiber reinforced PP into verified, repeatable production results through integrated material and structural development. This capability determines whether a material is truly usable in production rather than theoretically suitable.

Can glass fiber reinforced PP really withstand the loads required for automotive brackets?

The load-bearing performance of glass fiber reinforced PP in automotive brackets is the result of combined effects from material stiffness enhancement, structural design coordination, and injection molding quality rather than a single mechanical value. By controlling fiber content and managing flow-induced orientation, stable load paths can be formed in critical stress areas while maintaining cost and weight advantages. What truly determines load capability is whether the material system and bracket structure are designed around real operating conditions. In Xiamen Ruicheng projects, material characteristics of glass fiber reinforced PP are always evaluated together with installation conditions of automotive injection molded brackets to avoid gaps between theoretical performance and real-world failure.

Load sources: Loads on automotive brackets mainly come from vibration superposition and long-term static stress rather than single extreme impacts.

Material contribution: Glass fiber reinforcement increases flexural modulus and creep resistance, keeping deformation under control during continuous loading.

Structural coordination: Rib layout and wall thickness transitions significantly amplify load performance without relying solely on higher fiber ratios.

Practical validation: Bench fatigue tests and vehicle road simulations give engineering-level confirmation of load capacity.

🚗 Load performance depends on correct application, not just material strength.

Does higher glass fiber content always mean higher safety?

In automotive bracket design, higher glass fiber content does not automatically translate into higher safety, as excessive fiber ratios often increase brittleness, molding defect risks, and overall cost. The optimal fiber range should be derived from target loads, installation methods, and failure modes rather than simply matching datasheet values. A truly safe design balances sufficient load capacity with adequate toughness and a stable processing window. At Xiamen Ruicheng, material selection typically integrates glass fiber ratio design with injection molding process evaluation to prevent situations where parameters appear safe but finished parts fail.

Toughness balance: Moderate fiber content delays crack propagation under impact and fatigue loads.

Processing window: Excessive fiber increases risks of uneven flow and fiber breakage during molding.

Cost control: Material and processing losses rise noticeably with higher fiber content.

Application matching: Different bracket positions require different safety margins.

⚖️ Safety comes from balance, not from stacking material content.

Will injection molding processes weaken the structural strength of glass fiber reinforced PP?

The final structural strength of glass fiber reinforced PP is not fixed at the raw material stage but is reshaped during the injection molding process. Flow direction, shear rate, and mold temperature directly affect fiber orientation and thus anisotropic load performance. Without proper process control, even high-performance materials may fail in critical directions. Therefore, Xiamen Ruicheng integrates fiber orientation control with mold flow analysis to predict and correct potential weak zones.

Orientation effects: Fibers aligned with flow direction may reduce transverse strength.

Mold design: Gate location and runner balance determine fiber distribution uniformity.

Process stability: Temperature and packing fluctuations amplify strength variability.

Batch consistency: Stable processes ensure every bracket meets load requirements.

🛠️ Processing is not a step—it is part of the performance.

Decision Comparison for Glass Fiber Reinforced PP Automotive Bracket Solutions

| Comparison Aspect | GF Reinforced PP | Pure PP | PA + GF | Metal Stamping |

|---|---|---|---|---|

| Part Weight | Low | Very Low | Medium | High |

| Load Stability | Stable | Insufficient | Very High | Very High |

| Cost Control | Excellent | Excellent | Moderate | Poor |

| Production Consistency | High | High | Medium | Medium |

There is no universally “best” material—only the most suitable solution for a specific bracket role. To identify the optimal option for your project, feel free to contact us

Load Assurance Path from Prototyping to Mass Production

In automotive bracket programs, load performance is not confirmed once but gradually locked in throughout development. Xiamen Ruicheng ensures consistent load performance of glass fiber reinforced PP brackets through prototype validation, process freezing, and mass production monitoring. This approach significantly reduces late-stage redesign and production risks.

1.Prototype validation: Physical load and fatigue tests verify structural assumptions.

2.Process freezing: Material grades and molding windows are fixed after performance confirmation.

3.Process monitoring: Key parameters are tracked during mass production to maintain consistency.

4.Continuous optimization: Structural or process refinements are made based on field feedback.

Frequently Asked Questions (FAQ)

Question: What is the core advantage of your glass fiber reinforced PP automotive bracket solution?

Answer: The solution balances load capacity, lightweight performance, and cost stability, supported by controlled material grades and standardized molding processes to ensure consistent long-term performance.

Question: What information is required to quickly evaluate and receive a quotation?

Answer: Providing bracket drawings, installation details, target load conditions, and estimated annual volume allows Xiamen Ruicheng to perform a rapid feasibility review and propose a suitable solution.

Question: How are delivery timelines handled for different order volumes?

Answer: Small-batch validation can be completed within weeks, while large-scale programs follow tooling development and capacity scheduling, with support for phased deliveries.

Question: How are performance gaps handled if load tests do not meet expectations?

Answer: Material selection, structural design, and process assumptions are reviewed and optimized through fiber ratio adjustment, rib redesign, or process tuning until requirements are met.

Question: Do you support customization for special operating conditions?

Answer: Yes, detailed operating data such as temperature, vibration frequency, and installation constraints are required to develop tailored material and structural solutions.

Conclusion

Glass fiber reinforced PP injection molding is no longer merely a substitute material for automotive brackets but a mature and controllable engineering solution. Through coordinated material selection, structural design, and process control, its load performance can reliably cover most application scenarios. The true differentiator lies in the capability to convert material properties into stable mass production results. Choosing an experienced and systematic partner significantly reduces overall project risk.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!