Introduction

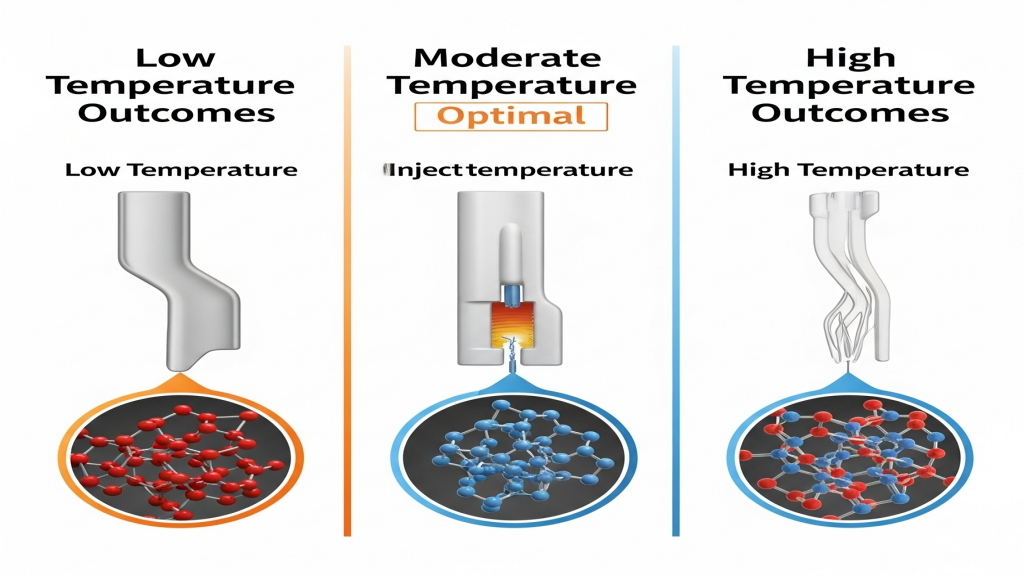

Mold temperature directly determines the crystallization rate and final crystallinity of polymers. A higher mold temperature allows molecular chains more time to align, thereby improving the physical performance of the part. In injection molding, mold temperature is a key factor in ensuring structural uniformity of parts.

On the other hand, excessively high or low mold temperature can cause uneven crystallization, leading to warpage or stress concentration. By precisely controlling mold temperature, a balance between production efficiency and quality can be achieved. Mold temperature control not only affects product appearance but also dictates long-term performance.

How does mold temperature affect crystallinity?

Changes in mold temperature influence molecular mobility and packing behavior. Proper mold temperature promotes better crystallization, while deviation from the optimal range may result in molding defects. A stable mold temperature environment is the foundation of consistent crystallinity.

- Standard Process Control: Keeping mold temperature in the recommended range ensures balanced crystallinity.

- Impact on Microstructure: Mold temperature changes the packing of polymer chains, directly affecting material strength.

- Energy and Efficiency Balance: Higher mold temperature may improve crystallinity but increases energy use and cycle time.

- Product Life Extension: Optimized mold temperature enhances durability and stability.

😊 Mold temperature control is essential for achieving uniform crystallinity and stable product performance.

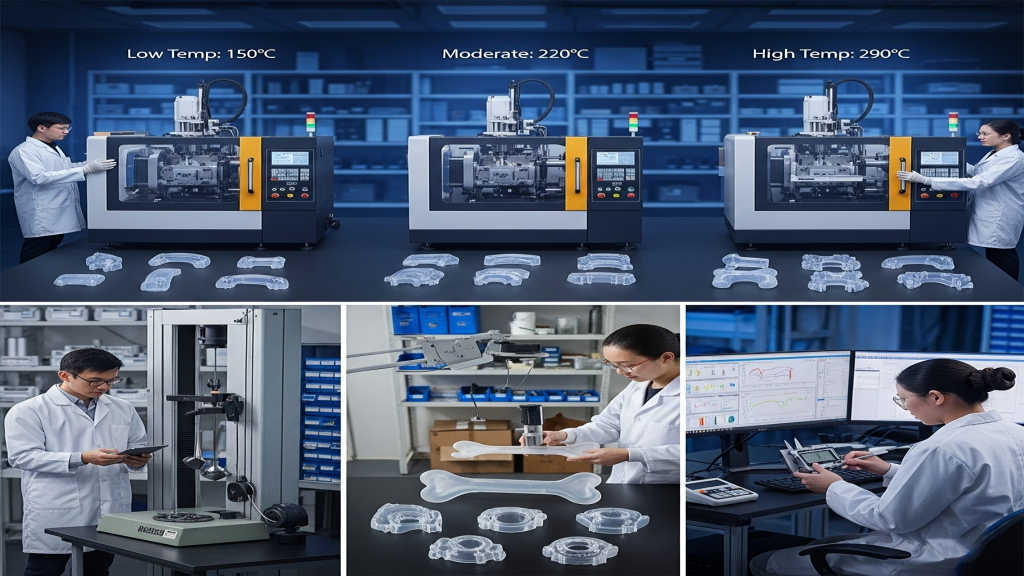

What differences do various temperature ranges bring to part performance?

At lower mold temperatures, parts cool too quickly, resulting in insufficient crystallinity and weaker strength. Moderate mold temperatures often yield optimal performance, while excessively high mold temperatures prolong cycle times and induce internal stresses. Performance differences stem from crystallization rate and molecular alignment.

- Low Temperature Risks: Rapid cooling reduces toughness and increases brittleness.

- Moderate Range Benefits: Balances production efficiency and stable mechanical performance.

- High Temperature Limitations: Longer cycle times increase unnecessary production costs.

- Structural Uniformity: Proper mold temperature ensures even property distribution.

⚙️ The choice of mold temperature range determines both performance and cost efficiency.

Can mold temperature control optimize crystallization defects?

Precise mold temperature regulation can correct uneven crystallization that causes stress or warpage. Adjusting mold temperature in critical zones minimizes weak points in the part. Mold temperature tuning is an effective method to improve crystallization defects.

- Localized Mold Temperature Control: Raising mold temperature in key areas reduces residual stress.

- Synchronized Temperature Systems: Advanced systems maintain uniform crystallization throughout the molding cycle.

- Surface Quality Improvement: Balanced temperature prevents weld lines and surface haze.

- Mechanical Performance Enhancement: Optimized crystallinity boosts impact and fatigue resistance.

🔧 Mold temperature control not only enhances crystallinity but also prevents defects and extends part life.

Comparison of Mold Temperature and Crystallization Performance

| Temperature Range | Crystallization Rate | Mechanical Strength | Cycle Efficiency |

|---|---|---|---|

| Low Temperature | Slow | Weak | High Efficiency |

| Moderate Temp | Balanced | Stable | Consistent |

| High Temperature | Fast | Strong | Longer Cycle |

| Unstable Temp | Uneven | Defect-Prone | Fluctuating |

Extension: Business Value of Mold Temperature Control

Mold temperature control is not only a technical matter but also a decisive factor in production efficiency and customer satisfaction. With smart temperature management systems, manufacturers can reduce defect rates and ensure consistent delivery. Strategic mold temperature control reduces costs while strengthening market competitiveness.

1.Efficiency Improvement: Precise mold temperature reduces rework.

2.Energy Optimization: Smart systems cut energy consumption.

3.Customer Confidence: Stable performance strengthens client trust.

4.Competitive Advantage: Advanced temperature control becomes a market differentiator.

Conclusion

The relationship between mold temperature and crystallinity is a core factor influencing injection-molded part performance. With scientific mold temperature control, manufacturers can achieve uniform crystallinity, stable properties, and efficiency at the same time. Mold temperature is the key to balancing quality and profitability.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!