Introduction

LSR (Liquid Silicone Rubber) injection molding is a highly precise manufacturing process widely used in medical, electronic, and automotive industries. By simplifying the process, significant improvements can be made in production efficiency and product quality. Reducing unnecessary steps in the production process not only improves efficiency but also cuts costs.

LSR injection molding requires precise control over material flow, ensuring the durability and consistency of the final product. Optimizing mold design and increasing automation levels can make the production process more efficient and cost-effective.

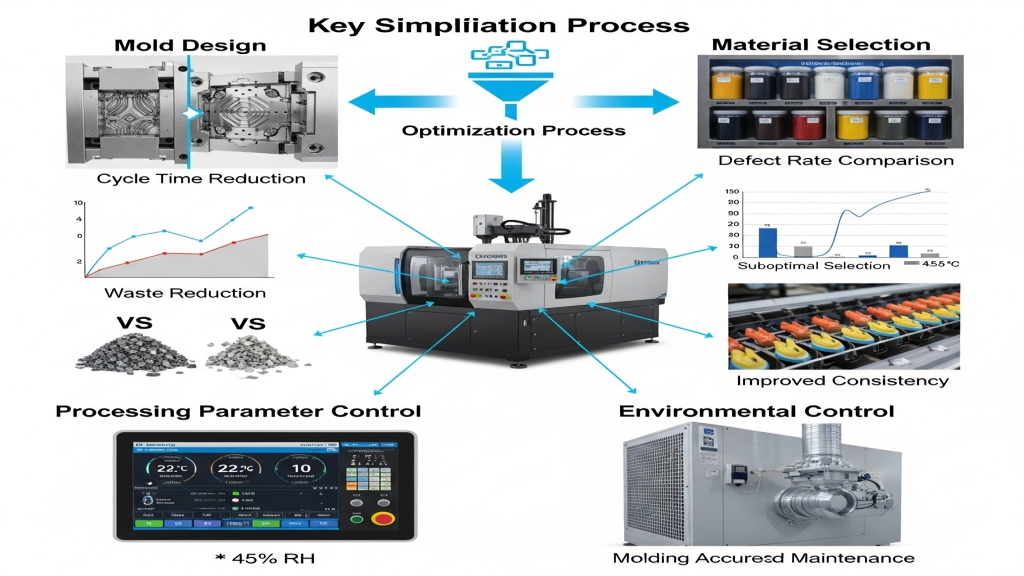

What are the key factors in LSR injection molding that affect the simplification process?

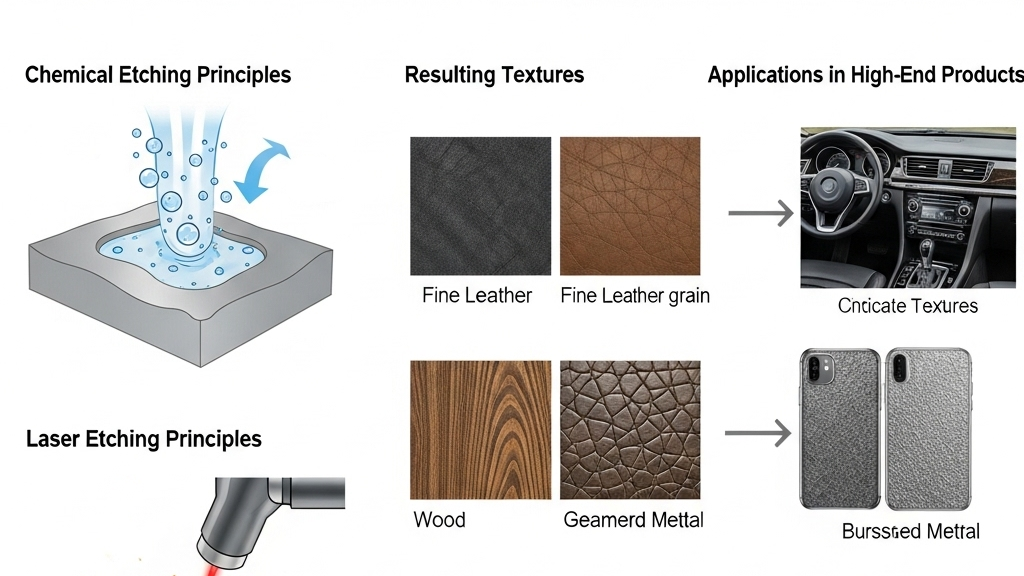

In LSR injection molding, the key factors for simplifying production include mold design, material selection, and processing parameter control. Accurate mold design and appropriate material selection can reduce waste and defects during production, making the process more streamlined. Proper mold design and optimized processing parameters can greatly improve production efficiency.

- Mold Design: A well-designed mold can reduce cycle time and eliminate unnecessary steps.

- Material Selection: Choosing the right LSR materials reduces defect rates and improves consistency.

- Processing Parameter Control: Increasing automation levels allows precise control over the manufacturing process.

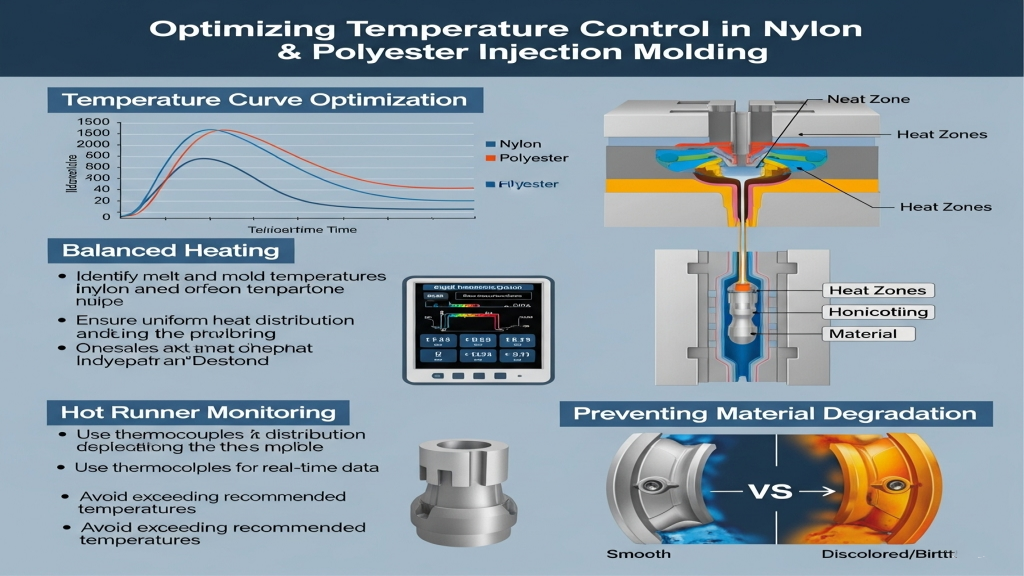

- Environmental Control: Temperature and humidity control is crucial for maintaining molding accuracy.

😎 The key to simplifying production lies in optimizing each step of the process.

How can optimizing injection machine parameters simplify the production process?

By adjusting the parameters of the injection molding machine, such as injection pressure, speed, temperature, and cooling time, production processes can be greatly simplified. These parameters directly affect the quality and cycle time of the molded products, so fine-tuning them can significantly increase efficiency. Precise injection machine settings ensure smooth and efficient production at every stage.

- Injection Pressure: Proper pressure control reduces material waste and ensures uniform mold filling.

- Injection Speed: Adjusting speed based on product complexity prevents overfilling or underfilling.

- Temperature Control: Mold temperature is crucial for ensuring material flowability.

- Cooling Time: Optimizing cooling time reduces cycle time and increases throughput.

🔥 Optimizing injection machine parameters is a direct method to simplify production.

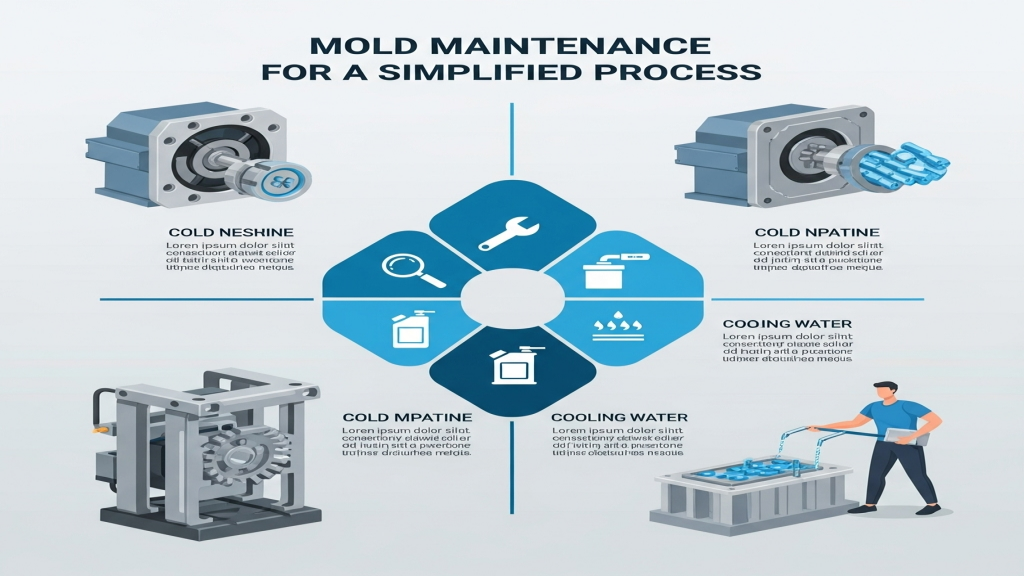

How does mold maintenance contribute to simplifying LSR injection molding?

Mold maintenance is essential for simplifying LSR injection molding. Regular maintenance prevents mold wear, extends mold life, and reduces downtime during production. Proper mold maintenance not only improves product precision but also reduces failure rates.

- Regular Inspection: Periodic mold surface checks prevent wear or damage that can disrupt production.

- Cleaning and Lubrication: Keeping the mold clean and lubricated reduces friction and extends mold life.

- Cooling System Maintenance: Maintaining cooling systems ensures product quality during molding.

- Replacing Worn Parts: Timely replacement of damaged parts prevents production delays.

🛠 Maintaining molds in good condition is foundational for simplifying the production process.

Table Title

| Item | Description | Optimization Focus | Impact Factors |

|---|---|---|---|

| Mold Design | Precise design reduces waste | Simplified design, higher efficiency | Material, structure, runner design |

| Material Selection | Choosing the right LSR material | Improved consistency, less waste | Material formula, curing time |

| Injection Machine Parameters | Precise settings improve efficiency | Fine control, faster production | Injection pressure, speed, temperature |

| Mold Maintenance | Regular checks and maintenance | Longer mold life, fewer failures | Cleaning, lubrication, part replacement |

Optimizing LSR Injection Molding Process for Production Simplification

Optimizing the LSR injection molding process can significantly improve efficiency and product quality. A simplified process reduces time waste and lowers production costs. In LSR injection molding, every detail of process optimization leads to more efficient production.

1.Mold Optimization: Ensuring efficient and precise mold design boosts production efficiency.

2.Material Control: Choosing the right materials reduces defect rates.

3.Automation Enhancement: Boosting automation simplifies the production process.

4.Maintenance Management: Regular maintenance and inspection extend mold life and reduce downtime.

Conclusion

Simplifying the LSR injection molding process can significantly increase production efficiency while lowering costs. Implementing these simplification measures allows businesses to enhance overall production capacity while maintaining product quality.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!